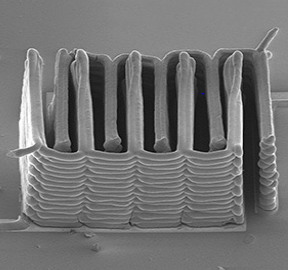

Harvard material scientist, Jennifer Lewis, is pioneering a new method capable of 3D printing lithium-ion batteries as tiny as a one millimeter square, yet as effective as commercial batteries significantly larger. Her technique uses an array of “functional inks that can solidify into batteries and simple components, including electrodes, wires, and antennas,” as well as high-pressure extruders that squeeze out the components from an industrial grade 3D printer. The batteries render microscale architecture and position with 100-nanometer accuracy in order to match the effectiveness of batteries 100 times larger.

The special inks are made from suspended nanoparticles of either lithium titanium oxide for batteries, or silver for wires, mixed with a vial of deionized water and ethylene glycol; the ensuing substance is nearly solid but flows when a certain amount of pressure is applied from an accurate extruder. Printing a single battery from one nozzle takes a few minutes; however, the Lewis’ custom 3D technology can equip hundreds of nozzles to multiply production.

The technique is revolutionary in that it can change the way electronics are manufactured, by 3D printing high-performing electronics and accompanying battery simultaneously. Hearing aids, and other devices that use a 3D-printed exterior shell, use separately manufactured electronics that are later inserted into the device, but printing them together will result in faster, cheaper and more effective production that should subsequently reduce consumer cost of acquisition.

Unlike traditional methods of 3D printing electronics reliant on high-temperatures, Lewis’ technique performs at room temperature, allowing it to print materials on plastic without causing any damage. The end results themselves aren’t unique per say, Lewis tells Technologyreview, but “this is really more of a revolution in the way things are manufactured.”

How are they made

Step 1: Nanoparticles of lithium-ion batteries oxide are combined with deionized water and ethylene glycol.

Step 2: Ceramic balls are added to the mixture to prevent any clumping of particles.

Step 3: The ink is spun for a total of 24 hours before the balls and any residual large particles are removed using filters.

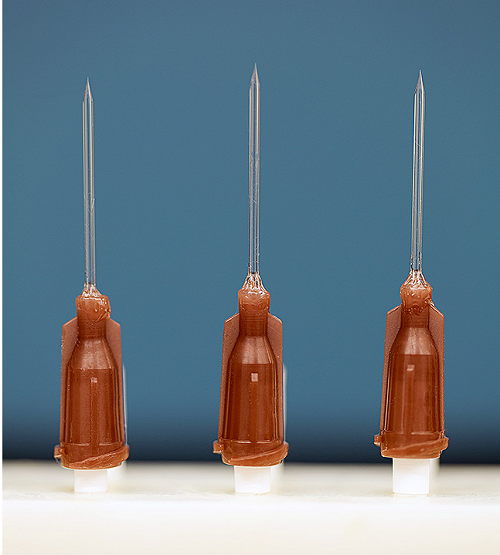

Step 4: Custom-made syringes with nozzles as small as one micrometer allow for precise patterning. The ink is placed into these syringes before they are inserted into a high-pressure dispenser (added to a conventional 3D printer).

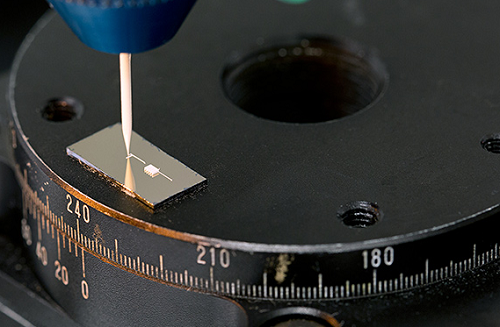

Step 5: Anode ink is extruded on a gold current collector patterned on a glass substrate.

Step 6: The printer extrudes layers upon layers of ink to form the battery’s cathode.

Step 7: End result shows a printed battery the size of a one millimeter block. Anodes and cathodes are arrange in a snake-like formation.

Story via Technologyreview

Advertisement

Learn more about Electronic Products Magazine