Using 3D printing and silicon carbide (SiC) semiconductors, researchers at the Department of Energy’s Oak Ridge National Laboratory have created a power inverter that could make electric vehicles lighter, more powerful, and even more efficient. The wide bandgap SiC material offers qualities superior to standard semiconductor materials and provides power inverters that convert direct current into the alternating current for powering the vehicle.

The researchers then took the design to the next level by using something called additive manufacturing. This is the official industry standard term (ASTM F2792) for all applications that use the process of joining materials to make objects from 3D model data, usually layer upon layer. This process helped researchers explore complex geometries, increase power densities, and reduce weight and waste while building the 30-kW prototype inverter.

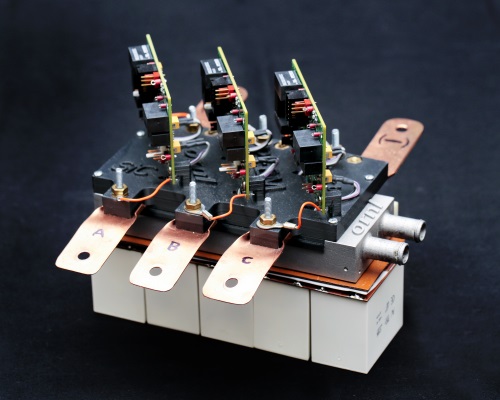

The Oak Ridge National Lab 30-kW power prototype inverter offers reliability and power in a compact package

Using 3D printing, researchers optimized the inverter’s heat sink, allowing for better heat transfer throughout the unit. This construction technique allowed them to place lower-temperature components close to the high-temperature devices, further reducing the electrical losses and reducing the volume and mass of the package.

Another key to the success is a design that incorporates several small capacitors connected in parallel to ensure better cooling and lower cost compared to fewer, larger and more expensive brick type capacitors.

The first prototype, a liquid-cooled all-SiC traction drive inverter, features 50% printed parts. Initial evaluations confirmed an efficiency of nearly 99%, surpassing DOE’s power electronics target and setting the stage for building an inverter using entirely additive manufacturing techniques.

Researchers are working on an inverter with an even greater percentage of 3D printed parts that’s half the size of inverters in commercially available vehicles. Researchers think that an inverter with four times the power density of their prototype is possible. For more information, go to http://science.energy.gov/

Advertisement