A group of engineers at UC Berkeley, working in collaboration with colleagues at Taiwan’s National Chiao Tung University, has introduced a possible solution to an issue we’ve all dealt with at one point or another: spoiled milk.

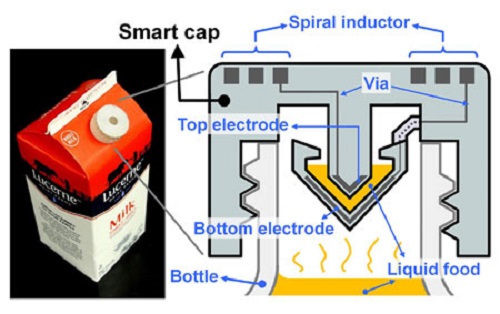

Their solution involves a 3D printed cap for milk bottles that is embedded with electronics for the purpose of wirelessly monitoring the freshness of the beverage. They describe their findings in Nature Publishing Group’s Microsystems & Nanoengineering open-access journal.

“Our paper describes the first demonstration of 3D printing for working basic electrical components, as well as a working wireless sensor,” said senior author Liwei Lin, a professor of mechanical engineering and co-director of the Berkeley Sensor and Actuator Center. “One day, people may simply download 3D-printing files from the Internet with customized shapes and colors and print out useful devices at home.”

Now, while this idea of creating a bottle cap embedded with microelectronics might sound simple enough, the road in getting there proved a bit complicated. Start with the fact that most of today’s 3D printed objects use polymers. This material is the primary choice among designers because it is very flexible which, in turn, allows it to be formed into all sorts of shapes and objects. It does come with a catch, though — it’s a poor conductor of electricity.

To overcome this hurdle, the team built a system using polymers and wax. When printed, they would remove the wax, leaving hollow tubes into which liquid metal was injected and cured (for those curious, silver was used in the team’s experiments).

The shape / design of the metal determined the function of different electrical components; for example, thin wires served as resistors, flat plates were made into capacitors, and so on.

At the time, this was all proof of concept work. When they reached the point that things were proving functional, they wondered — can all these pieces of metal do anything that’s actually useful?

Enter the milk cap idea.

The team integrated the electronic components into a 3D printed milk carton cap for the purpose of monitoring the beverage as it spoiled. This “smart cap” was outfitted with a capacitor and an inductor to form a resonant circuit. By doing a quick flip of the carton, some of the milk got trapped in the cap’s capacitor gap; after doing that, the entire carton when left unopened at room temperature (71.6 degrees Fahrenheit) for 36 hours.

During this time, the circuit was able to detect changes in electrical signals that accompany increased levels of bacteria.

Periodically, the team recorded the changes using a wireless radio-frequency probe; this was done at the start of the experiment and then once ever twelve hours thereafter.

Now, before we get into the results, it’s worth noting that the property of the milk changes as the beverage’s quality degrades; this leads to variations in its electrical characteristics. These changes were detected wirelessly using the smart cap, which found that the peak vibration frequency of the room temperature milk dropped by 4.3 percent after 36 hours.

For comparison purposes, a cart of milk kept at 39.6 degrees Fahrenheit in the refrigerator saw just a 0.12 percent drop in frequency over the same time period.

“This 3D-printing technology could eventually make electronic circuits cheap enough to be added to packaging to provide food safety alerts for consumers,” said Lin. “You could imagine a scenario where you can use your cellphone to check the freshness of food while it’s still on the store shelves.”

The team believes that this solution is representative of the bigger picture of things — that as 3D printers become cheaper and more accurate, the options for electronics will expand ten-fold. That’s not to say we’ll be printing out our own smartphones and tablets any time soon, though.

“That would be very difficult because of the extremely small size of modern electronics,” Lin said. “It might also not be practical in terms of price since current integrated circuits are made by batch fabrication to keep costs low. Instead, I see 3D-printed microelectronic devices as very promising for systems that would benefit from customization.”

Looking ahead, Lin and his team will be working on developing their technology for health applications; this includes implantable devices with embedded transducers that can monitor things like blood pressure, muscle strain, and drug concentrations.

Via UC Berkeley

Advertisement

Learn more about Electronic Products Magazine