By Gina Roos, editor-in-chief

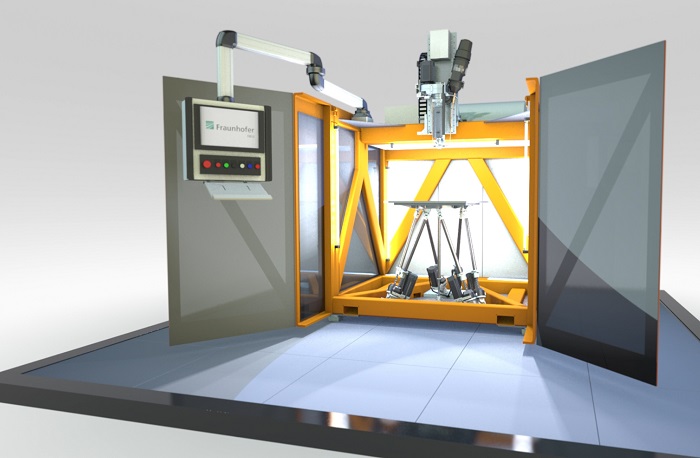

A new additive manufacturing system and process developed by researchers at the Fraunhofer Institute for Machine Tools and Forming Technology IWU produces plastic components eight times faster than conventional 3D printing while reducing materials costs. The new Screw Extrusion Additive Manufacturing (SEAM) system and process takes only 18 minutes to produce a plastic component that is 30 cm high, according to the researchers.

Fraunhofer IWU developed the technology for the additive manufacture of large-volume resilient plastic components. Up to 7 kg of plastic can be pressed through the hot nozzle with a diameter of 1 mm per hour using the SEAM system. In comparison, using 3D-printing processes like fused deposition modeling (FDM) or fused filament modeling (FLM) typically achieves only 50 grams of plastic per hour, said Fraunhofer IWU.

Another benefit is lower cost. SEAM processes standard plastic granules (instead of expensive FLM filament) into resilient, fiber-reinforced components that are several meters in size. Researchers said that this process lowers materials costs by a factor of 200.

In addition, this method can handle materials that previously couldn’t be processed by 3D printing. Fraunhofer researchers have tested a variety of plastics that are typically used in industrial applications, ranging from thermoplastic elastomers to polypropylene and polyamide-6 with a 40% content of carbon fibers (PA 6 CF). These materials are characterized by high stiffness and strength, or high elasticity, that can’t be processed by conventional 3D printers, said researchers.

The SEAM process can also generate various wall thicknesses within one printed path. As an example, the process generates strand widths between 1.2 and 3.1 mm for PA 6 CF using a 1-mm nozzle, depending on table speed and extrusion performance.

Watch the video:

The SEAM process “is highly significant for future further development of additive manufacturing technologies for industrial applications and constitutes a decisive step for increasing efficiency of 3D-printing processes,” said Fraunhofer. Markets that can leverage the new 3D printer include tool manufacturers and automotive and aerospace industries.

Fraunhofer plans to demo the ultra-fast 3D printer at Hannover Messe, Booth C22, Hall 2.

Advertisement

Learn more about Electronic Products Magazine