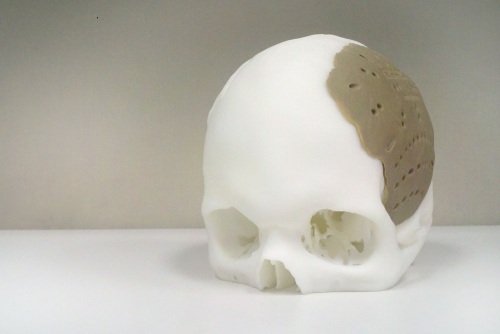

In a first of its kind procedure, an un-named patient has successfully had 75% of his skull replaced with a specially crafted plastic prosthetic that was made using a 3D printer.

A patient has had three-quarters of his skull replaced with a prosthetic produced via 3D printing.

Oxford Performance Materials received permission from the U.S. Food and Drug Administration for its skull implant on February 18, which led to the surgical operation being performed on March 4.

With the FDA's approval, the company says that it can now provide patients with 3D printouts to replace bone damaged by trauma or disease. The way it works is pretty straightforward: The company simply takes a 3D scan of the patient’s affected area and then prints out a matching 3D object layer by layer.

The printouts themselves, it should be noted, are much more than simple pieces of plastic: Each one features small surface details etched into the polyetherketoneketone to encourage the eventual growth of cells and bone atop the plastic.

Looking ahead, Oxford representatives say that about 500 people in the U.S. per month could make use of this technology, and that they can produce an implant within two weeks of obtaining 3D scans of the affected area.

Experts anticipate the market could be worth as much as $50 million to $100 million for each bone replacement type.

Story via: technewsdaily.com

Advertisement