In what could be a major telecommunications breakthrough, an engineer has developed a method for splicing together multicore optical fibers (MCFs) that could take the time consuming practice out of the lab and onto production lines.

Wenxin Zheng, manager of splice engineering at AFL, developed the technique and will be presenting it at the Optical Fiber Communication Conference and Exposition / National Fiber Optic Engineers Conference next week.

Why splice?

To understand why this is a big deal, it’s important to first understand why telecommunication engineers splice more than one optical fiber together into an MCF.

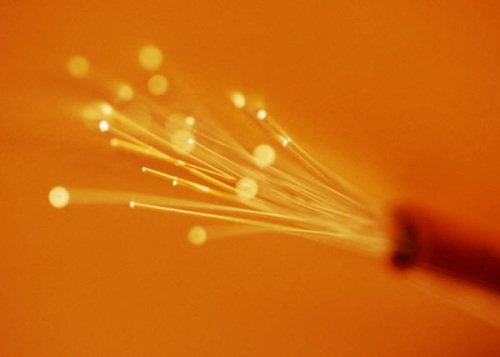

A single digital phone line uses 64 kilobits per second of bandwidth. To get more out of the fiber, an engineer introduces a method called “wavelength multiplexing” which, in layman’s terms, allows the core to send up to 200 different wavelengths of light at the same time. This method increase the capacity of the core up to 10 terabits per second, which, in real world functionality, allows it to serve about 200 million phone lines and support close to 1.5 million calls simultaneously.

Since these lines are so small, it makes sense to bunch / splice them together to increase a telecommunication company’s overall coverage in an area. At most, 19 multiplexed fibers can be spliced together to form an MCF. Doing this allows a telecommunications company to provide an area with up to 19 times the signal-carrying capacity.

The problem with splicing MCFs today

According to Zheng, the issue with today’s approach to splicing together MCFs is that the work is done mostly in the lab, where researchers have their own preferred manual process for aligning and connecting the fibers. He argues that the process should be perfected now to the point that it can be automated and moved to production lines instead.

“Although the manual way may be good for a skilled operator in a lab environment for research purposes,” Zheng says, “automation is the only path that can push MCF to factories and production lines.”

The Zheng solution

Zheng’s solution comes in the form of the Fujikura FSM-100P+ fusion splicer.

Fujikura FSM-100P+ fusion splicer is used for the automated alignment and splicing of MCF with PC control software developed by AFL.

To use it, fibers are stripped and then loaded into the splicer. Next, they are rotated and imaged with two video cameras that (approximately) align the cores together using a pattern-matching algorithm. After that, the machine uses power-feedback and image processing to finely align pairs of corresponding cores together. Once that step’s complete, the cladding around the cores is aligned and all of the cores are heat-spliced together.

“To align the multiple cores simultaneously is a big challenge,” Zheng says. “If two fibers to be spliced have random core locations, there is no way to align the entire core.” There is, however, a solution to this minor headache — the component cores of MCFs can be aligned if they are created using the same design standard, and if the cores are distributed symmetrically in the MCF. If this is the case, Zheng notes, “we can fine-align one side-core in an MCF and its cladding at the same time. Based on the geometric specifications of the fiber, the rest of the cores will be automatically aligned.”

Presentation

If you’re planning on attending the event, Zheng’s presentation “Automated Alignment and Splicing for Multicore Fibers,” is on Monday, March 18, at 5 p.m in the Anaheim Convention Center.

Via: opticsinfobase.org

Advertisement