Energy efficiency is one of the most misunderstood aspects of fractional horsepower motors and gearmotors. It normally does not receive much attention; however, efficiency can be critically important to an application. By examining motor and gearmotor efficiency from several different angles, it becomes clear that efficiency concerns affect, and are affected by, the other characteristics of an application. We will take a deeper look at the effects of efficiency and requirements and tradeoffs of an application.

Of course: Power In × Efficiency = Power Out

When discussing efficiency as it relates to fractional horsepower motors and gearmotors most engineers primarily think about how it relates to cost. While this relationship is important, efficiency is also intertwined with many other critical design considerations.

Costs

So, cost is the most obvious considerations. Many designers do not stop to consider the whole picture, when it comes to cost and efficiency. Often efficiency is only thought of in terms of energy cost but efficiency also affects the purchase cost. Many engineers do not stop to consider the increased system cost related to powering a low efficiency gearmotor. Almost every component of an electrical system must be sized based on current draw. Higher current means heavier gage wires to the motor, larger relays, etc.

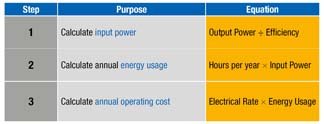

Fig. 1: Determining operation costs.

Operating costs (see Fig. 1 ) are determined by, first, using efficiency and output power to calculate input power and then multiplying the hours/year and input power to establish the energy usage. Then your electrical rates are used for the annual operating cost.

Let's take a look at an example (see Fig. 1 ). Let's say we have a ½-hp motor (373 W) that is 70% efficient. This would require an input power of 533 W. If this motor were to be run 8 hours a day, 7 days a week, the yearly number of hours would be 2,912. The annual energy usage at this duty cycle would be 1552 kW-hrs. At an electrical rate of 12 cents/kW-hr, annual operating cost would be $186.24.

Energy usage

Typically, when designing an application, the gearmotor's output power is calculated based on what is needed in terms of mechanical output. Unfortunately, many designers fail to take the next step, which is to calculate the electrical energy needed to drive the gearmotor. An electrical energy value is required to ensure that the power supply is sufficient for the application. This will also give an idea of the efficiency needed for the gearmotor. In an application where there is barely enough power to supply the motor, special attention is needed.

General design

Consideration needs to be given to all aspects of the system that are affected by the efficiency of the components, as efficiency is intertwined with all the parts. For example, efficiency can be affected by the size and weight of the motor. One of the primary factors driving gearmotor size is heat dissipation. A gearmotor's ability to dissipate enough heat is dependent in part on its surface area. Since heat is the primary form of energy loss in motors, increasing efficiency will decrease heat and allow the use of a smaller gearmotor.

Environmental factors and regulations

Often, only the environmental impact of the energy the gearmotor uses is considered. However, if you really want to take into account all the environmental perspectives, the energy to manufacture the gearmotor should also be considered. For that you need to request information from the manufacturer.

There are not many regulations that pertain directly to fractional horsepower motor energy usage. However, there are many different regulations, such as the 1992 Energy Policy Act (EPAct) and Energy Independence and Security Act of 2007 (EISA), that apply to various end products where fractional horsepower motors are used, and gearmotor efficiency must be accounted for in order to help meet regulations.

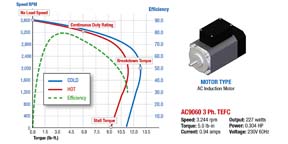

Fig. 2: Speed, torque, and efficiency curve for an ac induction motor.

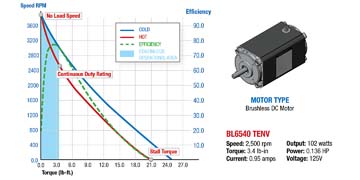

Finally, it is important to understand how a motor or gearmotor's efficiency depends on its load. Efficiency is often thought of as a single number, but in reality a motor's efficiency varies with the load. By definition, the efficiency will always be zero with no load and also when a motor is stalled. For example, notice in Fig. 2 , between those two points the efficiency will increase, reach a maximum value and then decrease. Because of this we can see the importance of properly sizing a motor. Both undersized and oversized motors can be inefficient. Gearbox efficiency also varies with load. Because of this it is important to properly size the gearbox to the motor in a gearmotor application. Figure 3 shows a similar curve for a brushless dc motor.

Fig. 3: Speed, torque, and efficiency curve for a brushless dc motor.

Advertisement

Learn more about Groschopp