Pressure sensors have gotten more capable and are tackling a wide variety of applications in which measuring pressure doesn't seem to be the point. Among the following sampling of pressure sensing devices from major suppliers, you'll find devices that serve as altimeters and replacements for ultrasonic and radar devices, as well as ones who tackle pressure measurement in novel ways.

Measurement Specialties (www.meas-spec.com ) recently released the MS5805a miniature altimeter, actually a low-power digital barometric pressure sensor. The sensor's high precision — it integrates a 24-bit delta-sigma ADC — suits it for portable, battery-operated devices such as fitness gadgets, bike computers, adventure or multimode watches, variometers, and dataloggers. The sensor interfaces to virtually any microcontroller to optimize design flexibility.

Measurement Specialties' MS5805a miniature altimeter

With a conversion time down to 0.5 ms via an I²C interface, the device works from a 1.8 to 3.6-V supply, consuming just 0.6 μA in operation and less than 0.1 μA in standby mode at 25°C. The fast conversion time includes an oversampling selection of up to 8192, allowing exceptionally low noise performance. With resolution of 0.02 mbar (equivalent to a 20 cm change in elevation), the integrated digital pressure sensor has a pressure accuracy of ±4 mbar for pressures ranging from 300 to 1,200 mbar and temperatures of −20° to 85°C. Further, it is splashproof down to 40 m and includes temperature measurement capabilities with an accuracy of ±2°C and a temperature resolution less than 0.01°C. It is priced at $5.25 per unit in quantities of 10,000.

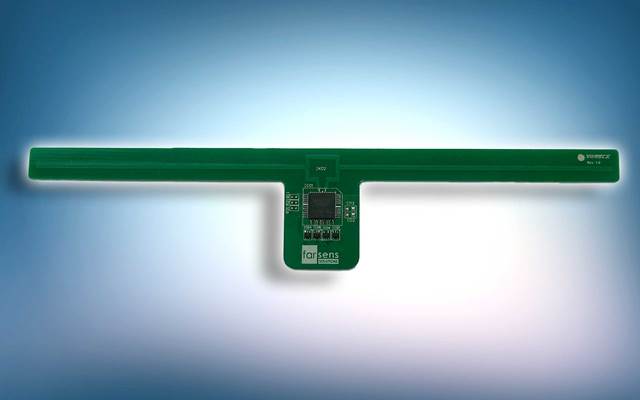

The Vortex1 from Farsens (www.farsens.com) is a battery-free RFID sensor tag capable of transmitting pressure data along with a unique identifier to a commercial EPC C1G2. The device features a LPS331AP pressure sensor from ST Microelectronics with an absolute pressure range from 260 to 1,260 mbar. The tag comes in a variety of antenna designs and sizes to adapt the performance to the required application. The reading distance for the battery free pressure sensor tag is around 1.5 m and it can be embedded in a wide variety of materials, such as plastics or concrete. Evaluation kits are available.

Farsens' Vortex1

The tag is designed for monitoring pressure-sensitive assets and process management. That it needs no wiring simplifies retrofitting piping systems, gas/liquid containers, or similar assets and processes due to the low installation investment required and the savings associated to sensor maintenance due to battery changes.

American Sensor Technologies (AST, www.astsensors.com) has released the AST46DS explosion-proof pressure transducer with display. Available for pressures from 1 to 20,000 PSI, the sensor is price-competitive, and offers zero function capability, voltage or 4 to 20-mA output signals, and all 316L stainless steel sensor materials.

American Sensor Technologies' AST46DS explosion-proof pressure transducer with display

The voltage output signal suits oil and gas well site applications. With many SCADA / RTU sites powered by solar panels in remote locations, a pressure transducer with low current consumption can have an extended operating life; the AST46DS can operate as low as 8 Vdc and has current consumption as low as 2 mA. For offshore platforms, the transducer housing has a special layered paint suitable for NEMA 4X environments and salt spray conditions. Using 316L stainless steel, the $825 transducer is compliant to NACE MR0175/ISO 15156.

AST has also introduced the AST4530 PVDF / PTFE submersible pressure transducer with measurement ranges from 0 to 2.5 psi up to 30 psi. Intended for liquid-level measurement of corrosive liquids in which stainless steel or titanium cannot survive, the AST4530 is designed to offer excellent long-term survivability and stability.

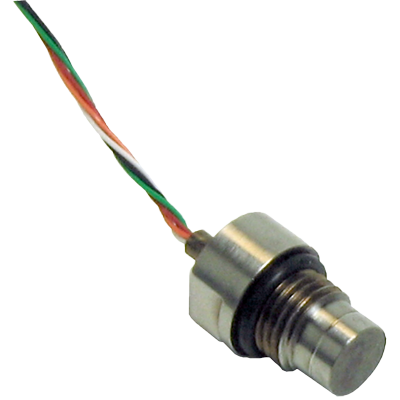

American Sensor Technologies' AST4530 PVDF / PTFE submersible pressure transducer

Submersible pressure transducers offer some flexibility in comparison to ultrasonic and radar level sensors. Vapors generated from the liquid will not affect the sensing element of a submersible pressure transducer, since it is designed for optimal compatibility. Foaming or reflections of the liquid will not generate false readings, because the sensor measures liquid pressure based on specific gravity.

All exposed sensor materials are optimized for compatibility, including the PVDF cable and seal. Changes in pressure are transmitted through a PTFE diaphragm and converted to an output signal using ASIC electronics. Ratiometric 1 to 5 and 0.5 to 4.5-V outputs are available for low-current-consumption applications, whereas a 4 to 20-mA output is available long distance transmissions. The $595 submersible transducers are vented to atmosphere through the cable for optimal accuracy.

Honeywell Sensing and Control (measurementsensors.honeywell.com) is now offering the Model S Series of subminiature pressure transducers. Featuring 1% accuracy, the sensors fit into tight spaces with little clearance, and measure pressure ranges from 100 to 15,000 psi. The rugged transducers are designed to handle high temperatures as well as pressures, and have a flush diaphragm manufactured from 17-4 PH stainless steel with a high natural frequency for applications such as engine and transmission test stands, pressure brake testing, and hydraulic sensor testing.

Honeywell Sensing and Control's Model S Series subminiature pressure transducer

Temperature compensation is accomplished by using temperature-sensitive components inside the transducers. These transducers have a small electrical zero-balance circuit board, which is in the lead wire (approximately 1 in x 0.087 in thick). This balance board does not have to be in the same temperature as the transducers. All transducers have four active, bonded strain gages arranged in a Wheatstone-bridge configuration.

Honeywell also introduced two new Wing Union / Hammer Union pressure sensors for such applications as oil and gas drilling, mud pumps / mud logging, fracturing and cementing, acidizing, well-head measurement, and standpipe stimulation. The model 425 is available in two accuracy levels (±0.2% or ±0.1% BFSL), while the Model 427 (±0.2% BFSL) provides a wide and shallow sensing port that facilitates seamless flow of more viscous media blends.

Honeywell Sensing and Control's Wing Union / Hammer Union pressure sensors

Both feature all-welded one-piece, hermetically sealed, stainless-steel construction and Inconel X-750 wetted parts for additional durability with abrasive or corrosive media. Multiple electrical connections are available and the units are RFI/EMI protected, CE approved available with an intrinsically safe option, and have CSA/ATEX certification.

Advertisement

Learn more about American Sensor TechnologiesHoneywell Sensing and Productivity SolutionsMeasurement Specialties