Due to the high complexity and networking of their control devices, today's vehicles require the utmost in reliability from individual electronic components. Power-hungry electrical applications demand a higher generator voltage, low-loss switching regulators, and intelligent energy management in order to handle the energy requirements with maximum efficiency. Environmental sensors, active safety systems, and driver assistance systems require faster and faster analog signals that must be transmitted without interference. Furthermore, components are subject to extreme temperature fluctuation, moisture, heavy vibrations, and high operating temperatures.

To contend with all of these factors, popular standard assemblies such as resistor chips, multilayer ceramic chip capacitors (MLCC), and aluminum capacitors are often the first components that come to mind for designers. However, to meet the specific requirements of automotive applications, custom passive components are being used more and more frequently. Their increasing significance is demonstrated in the following applications.

Reducing EMI

In order to ensure the frictionless function and communication of the many electronic devices in the vehicle — often produced by a variety of component manufacturers — car manufacturers define strict specifications to control electromagnetic interference (EMI). In order to meet these increased demands for electromagnetic compatibility (EMC) as efficiently as possible, while also meeting requirements for compact footprints and low energy loss, fully shielded surface-mount inductors are available that use powered iron power technology at frequencies up to 1.0 MHz. Such devices provide an excellent saturation reaction over a wide load and temperature ranges to +155°C. The inductors can be optimized for use as an EMI filter or for energy storage.

Fig. 1: Vishay IHLP Series inductors feature powdered iron technology with inductances from 1 to 22 µH.

Various types of ceramic capacitors are targeted at suppressing radio frequency interference (RFI) in automotive applications. Offering excellent filter properties and AEC-Q200 certification, available products include multilayer ceramic chip capacitors (MLCC) with axial, radial, and surface-mount configurations. Select devices are available with extremely high maximum approved operating temperatures to +160ºC, with wired MLCCs offering temperatures to +175ºC soon to be available.

Automotive-certified feed-through capacitors provide even better suppression of high-frequency EMI. Their ceramic hollow cylinder functions as a dielectric. With their low impedance at high frequencies, they can filter EMI to the earth. In the very-high-frequency range of >100 MHz, the application of a feed-through capacitor can improve the suppression of EMI to the point of eliminating it almost completely over the full frequency range. They are often needed in electronic devices for which the vehicle manufacturer has defined particularly stringent criteria for electromagnetic emission.

Start-stop and hybrid vehicle technology

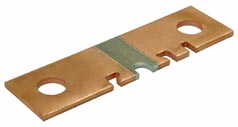

Another interesting and rapidly growing use for special passive components is bidirectional, intelligent current measurement for start-stop and hybrid electric vehicle (HEV) technology. The intelligent current measuring resistor is a key component in start-stop solutions for monitoring energy consumption. Most car manufacturers require specific solutions. Manufacturer-specific requirements can be met with fully integrated solutions, such as a shunt resistor, an ASIC, and an interface with a manufacturer-specific connection all in a single package. For these integrated solutions, resistors are available that enable continuous currents of up to 1,000 A, and current surges up to 3,000 A.

Fig. 2: A Power Metal Strip cross resistor enables accurate high current measurements.

Moreover, efficient voltage converters are required to cater to the various energy requirements in all the vehicle's operating statuses. Here, where high efficiency is of the utmost importance, compact, manufacturer-specific planar transformers with dielectric strength up to 3 kV meet requirements. They offer an excellent galvanic separation, high efficiency, low loss, and high reliability for inverters providing an output exceeding 1 kW and operating at over 60 V. Using inductors with an extremely low dcr as a filter at the input or output ensures effective interference signal suppression and low loss.

Film capacitors can ensure the necessary charge storage in the intermediate circuit and are used as filters in combination with inductors. High-voltage thick film resistors are used as charging and discharging resistors for transformer charge storage in start-stop.

Miniaturization, smaller dimensions

The increasing number of electronics assemblies in modern vehicles is requiring smaller sizes. Tolerance ratings are becoming lower and lower, as well as temperature coefficient specifications. Integrating several resistors on a single ceramic carrier, thin film resistor arrays provide a good way to meet the need for space savings, greater precision, and stability.

Fig. 3: The AEC-Q200-qualified ACAS AT thin film resistor array features two or four 0603 resistors.

Thin-film resistor arrays are also used where the relative accuracy plays an important role. Due to heat conduction, radiation, or convection via adjacent assemblies, different local ambient temperatures normally arise on a printed-circuit board. Resistor arrays offer a good way to guarantee a constant relative temperature for all resistors in the package for uniform behavior. Thin-film resistor arrays are used in voltage dividers, op amp feedback circuits, and dc/dc converters. The highly heat-conductive ceramic ensures that all the resistors are at the same temperature.

Advertisement

Learn more about Vishay Intertechnology