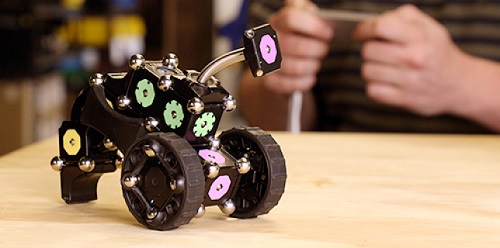

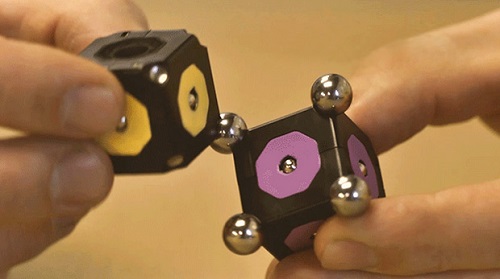

MOSS is a robot construction system that’s a delicate dance of form, function and accessibility; users build robots by snapping together modules with magnetic carbon steel spheres – no programming or wiring necessary. Simply decide what to build and stack the corresponding modules while enjoying the tactile click of assembly. Color coded surfaces signify a module’s purpose and deliver power and data flow through a single button contact while passing ground through the steel spheres.

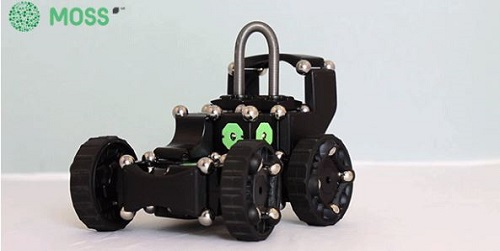

Snap together modules and spheres to create robots that react to their environment

Developed by Modular Robotics, the same group responsible for the Cubelets robot building kit, MOSS advances everything learned from its predecessor to a more sophisticated level, allowing you to build Bluetooth controlled robots that detect distance, sound and light, fire nerf rockets, shuffle paper, and many more option. Various kits and expansion packs serve different purposes, yet provide unlimited customization based on how you choose to arrange the modules.

MOSS kits are designed for fast and inexpensive assemblage, says Modular Robotics CEO Eric Schweikardt, and take significantly less time to assemble than Cubelets. For this reason, they are completely assembled in United States straight out of MR’s factory in Boulder, Colorado, in order to create a more competitive pricing while simultaneously establishing domestic job opportunities.

Modular vs traditional robotics

In short, “form is function [in modular robots],” says Eric Schweikardt. Unlike traditional robotics that require piecing together body parts before programming the “brain,” by laptop, both body and behavior are determined by snapping together MOSS components. The resulting robot will perform differently depending on the arrangement of modules. Nevertheless, this is merely scratching the surface of what MOSS can do. By adding an iOS or Android device, along with the Bluetooth module, to the mix, you’ll be able to communicate and control your MOSS robot wirelessly from your smart device. Modular Robotics has already released three proprietary apps aimed at extending functionality beyond the physical structure, and will announce a new app as a stretch goal at $286,000, Schweikardt tells Electronic Products.

How does it work?

Snapping together MOSS modules is all you need to fashion a static structure; however, making a functioning robot actually requires you to pair color coded surfaces on the modules themselves. For instance, yellow surfaces conduct power and are placed on all modules that require power. Alternatively, battery modules are completely covered in yellow faces, permitting them to be inserted in multiple ways across your robot. Powering a module is as easy as pairing one of its yellow surfaces, directly or indirectly, with a battery module’s yellow surface – all that’s requires is snapping the steel sphere into magnetic hinges.

MOSS uses overmolded neodymium, rare-earth magnets, to produce enough magnetic force needed for a firm grip. One of the biggest challenges in up-scaling Cubelets to MOSS was producing enough of a hold so people could build large constructions, Schweikardt said to Electronic Products, “We solved this with custom rare-earth magnets that have a concave face for maximum contact with the steel spheres.”

Alternatively, controlling the speed of a spin module with a distance sensor requires that the distance sensor’s data-out surface, its blue surface, connect to the spin’s green data input. Occasionally, the pink passthrough surface of a flexible module may be required to bridge power if battery module is a few units away. The number of modules that can be included in a design is unlimited and multiple battery modules can be stacked to increase overall run time of robust MOSS constructions.

Early adopters may acquire their MOSS kits from the project’s Kickstarter campaign. Worthy of esteem is the fact that MOSS fulfilled its campaign goal within the first twelve hours of launch – a rare feat for even the most popular campaigns. MOSS’ success can attributed as a sign public support and appreciation, a hopeful indicator of the coming proliferation of modular technology.

Advertisement

Learn more about Electronic Products Magazine