Instead of acquiring a 3D printer to make useless knick-knacks that ultimately go in the garbage, why not grab one that makes something a bit more practical, like a printed circuit board? We can all agree that the process of building a PCB by hand is a right-of-way that all electronic hobbyists and makers ought to know, but the process is time consuming, often taking as long as an hour before the end product is ready for testing. EX¹ is a 3D printer designed exclusively for making PCBs, and having a ready to use circuit within a couple of minutes; it’s as easy as selecting file and then print.

EX¹‘s underline principle is simple: to change the way we make electronics in the same way 3D printers changed the way we make physical objects. Cartesian Co., the designers of EX¹, want to make creating electronics as accessible as printing a picture with a desktop printer.

What can you make?

EX¹ prints circuits on a majority of surfaces, ranging from plastics to more unconventional ones, including glass, wood, ceramic, silicone, fabric, and even paper. If this repertoire is deemed limited, rest assured, Cartesian Co. is developing a coating that allows almost any surface to be printed on. Fabric printing is a monumental expanse in DIY possibilities, allowing anyone to their focus into wearable computing without having to spend grueling hours sewing a circuit with conductive thread.

Create binary watches, fitness and heart monitors, etc.

How does it work?

To print images on a substrate, EX¹ uses two inkjet cartridges similar to the ones in your desktop printer, but lays down silver nitrate and ascorbic acid (vitamin C) – instead of ink. When these two chemicals mix, a reaction occurs producing silver nano-particles that leave a conductive silver image on the substrate. The connectivity of the silver nitrate is as dependable as that of copper traces.

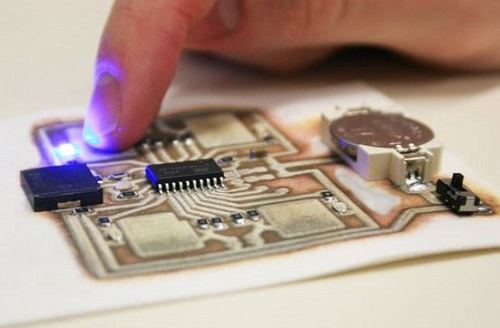

Arduino compatible microcontroller printed on kapton and wood.

The specs

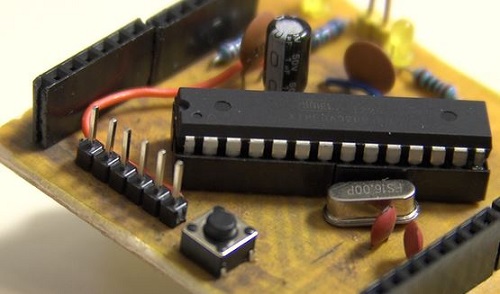

The printer features a 600 dpi resolution and can reliably cram tracks and pads, with a spacing of up to 1.27mm, down to SOIC components. EX¹ weights 6kg (13.5lbs) and measures 43 x 32 x 17cm (17 x 12.6 x 6.7in) – approximately the size of the typical home inkjet printer. The printer features a print area of 17.5 x 8cm (6.9 x 3.2in) to ensuring that any board designed on the free Eagle software can be printed.

br />

Software

The primary goal when designing EX¹ was to transfer the ease of access of using (most) conventional home printers onto printing circuit boards. Nevertheless, printing a photo differs from printing a circuit. For this reason, Cartesian Co.’s proprietary software strives to simplify circuit design as much as possible. Of course, prior knowledge of electronics is required, at least a fundamental sort, but the software comes equipped with presets and tools to make the process as intuitive as possible, whether that entails having complete control of every variable or importing an image and clicking print.

Soldering

Depending on your skill level, circuits can be soldered as necessary, or if you think yourself too much of a novice to use molten metal, then conductive glue may be substituted. Cartesian Co. claims to have found success with this approach, comparing it to finger painting, especially if the circuit was printed on a paper medium.

Visit EX¹’s Kickstarter page to procure your own unit.

Advertisement

Learn more about Electronic Products Magazine