Supercapacitors are advantageously positioned between capacitors and batteries in the electronic component taxonomy. A single supercapacitor can store far more energy than a conventional capacitor with a solid dielectric. Storage capacity lags that of batteries. But, when supercapacitors can store sufficient energy for the application, they have several advantages, including their ability to turn on instantaneously, charge quickly, and require less complicated charging circuits.

For electronic design engineers, other important supercapacitor characteristics include high power densities and very long lifetimes regardless of the number of charge cycles. This is a distinct advantage over batteries.

These characteristics complement many new applications characterized by widely varying energy requirements such as with smartphones. In these applications, they can be used to extend battery life. Supercapacitors are also displacing both conventional capacitors and batteries in many mature applications.

Supercapacitor fundamentals

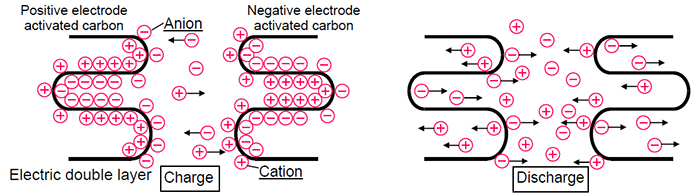

Instead of storing energy using a solid dielectric like conventional capacitors, supercapacitors involve two layers and are often referred to as EDLCs (electrochemical double-layer capacitors). In an EDLC, a physical mechanism generates the electric double layer that performs the function of a dielectric. The charge-discharge cycle is created through an ion absorption layer at the surface of the positive and negative activated carbon electrodes. The distance of the static separation of charge in an EDLC double-layer is extremely small – on the order of 0.3 to 0.8 nm. Figure 1 shows the ion activity for the charge (left) and discharge (right) cycles.

EDLCs typically store electrical charges in activated carbon electrodes

Figure 1: EDLCs typically store electrical charges in activated carbon electrodes (Courtesy of Panasonic).

EDLCs use ion migration inside a thin membrane of activated carbon to store electrical charges. Applying a voltage across the capacitor’s two electrodes causes the ions in the electrolyte to migrate in an attempt to reverse the charge on the electrodes (the charging part of the cycle). Positively charged ions move to the negative electrode and negatively charged ions move the positive electrode, forming two charged layers inside the electrolyte: one positive and one negative. Removing the voltage causes the ions to move in the opposite direction, creating the discharge half of the cycle.

The capacitive values of supercapacitors are determined by their size, geometry and composite materials. The capacitance of a device with aluminum electrolytes ranges from 10-6 to 10-2 F (farad). Panasonic’s line of gold supercapacitors offers a capacitance values up to 70 F. Rechargeable batteries used in consumer products offer much higher capacitances – how much higher depends on battery size.

Exotic materials will provide another boost for supercapacitors in their competition with battery technology. Researchers have fabricated graphene devices that store as much energy as NiMH batteries – on the order of 85 Wh/kg at room temperature. Typical of all supercapacitors, they still charge very quickly – in a matter of seconds or minutes.

The increased capacitance displayed by the new devices built with conducting polymers derives from a charge-storing principle known as pseudocapacitance, which is created by a chemical reduction-oxidation (redox) reaction at the electrode. Typically, the ion is O2+. During the charge cycle there is a reduction reaction at one electrode, while the other electrode experiences an oxidation reaction. During discharge, the reaction is reversed and the ions move in the other direction across the electrolyte.

Together double-layer capacitance and pseudocapacitance determine the capacitance value of a supercapacitor. The relative contributions vary widely and depend on electrode design and electrolyte compositions. In some instances, pseudo-capacitance increases capacitance value by as much as an order of magnitude over that of the double-layer by itself.

Application spaces

At the high end of the energy storage spectrum, supercapacitors are being used to increase the efficiency of hybrid electric vehicles in several ways. Today’s hybrid vehicles typically turn off the engine completely when the car comes to a stop, however briefly, and then very efficiently start it again using energy stored in supercapacitors. Maxwell Technologies offers a line of supercapacitor-based modules that range up to 3000 F. It has sold over 600,000 supercapacitors for this start-stop application in hybrids.

Maxwell has also designed a replacement for a conventional vehicle battery using supercapacitors connected across a smaller lead acid battery. The concept behind this application is that power demand spikes, such as starting a car, decrease the overall energy that the battery can produce. Batteries last much longer when the discharge is small and steady. The supercapacitors in Maxwell’s “hybrid” lead-acid battery essentially smooth out energy demands on the battery.

Other component vendors with supercapacitor lines targeting various markets include Nichicon, AVX, Murata, Cornell Dubilier, and Vishay.

Trains, planes, and automobiles (as well as trucks) account for about 40 percent of today’s $400 million worldwide supercapacitor market, according to market researcher Paumanok Publications Inc. Transportation applications include maglev trains, power and braking recuperation systems, truck lifts, and track switching.

Of more interest to the typical design engineer are consumer electronics, computer, and communications applications. Supercapacitors are frequently designed into these products for memory protection. Internal back-up power is another common application. The supercapacitor can be used either as a battery replacement or as a short-term redundant back-up supply.

With the steadily increasing deployment of smart meters, power back-up for electric and gas meters is getting more attention, because if the mains power fails there is a good chance the meter will fail as well. Rechargeable batteries are the conventional design choice but they require a charging circuit, which increases the cost of the design for handling a situation that is relatively rare.

The two main requirements for smart meter back-up are (1) that the source is capable of turning on instantaneously; and (2) that it works at low temperatures, because meters are typically installed outdoors. Supercapacitors excel in both requirements as they react immediately, allowing the meter to transmit an alert as well as status and usage information to the network.

Integrating a supercapacitor backup involves less design effort than recharging a battery, but the same charge-controller ICs tend to be used for both applications. Although the power supply is simpler for supercapacitors than for battery chargers, there are still some design pitfalls to be avoided. Using a diode to prevent reverse current, for example, would cause the supercapacitor’s charging threshold to rise by the amount of the diode drop. Using a regulator instead, eliminates the diode drop problem and lowers the charging threshold. This strategy becomes problematic when the supercapacitor becomes depleted because the supercapacitor takes longer to charge.

Data sheets and application notes from suppliers of power management ICs provide the best practices for power supply designs. Texas Instruments’ bq24640and Maxim Integrated Products’ MAX17710 are two examples.

Supercapacitors are also used to protect CMOS logic and to power electronic toys. Security alarm systems, uninterruptible Power Supply (UPS) systems, and solar power are other common applications.

Until recently, the supercapacitor market has grown largely at the expense of conventional capacitors. Currently, the technology seems ready to invade the lithium-ion battery market share for smart phones and other devices that perform multiple functions more or less simultaneously, and therefore, have similar spiky power-to-available-energy profiles.

The total potential energy content of lithium batteries drops if energy is extracted quickly. In other words, demand for immediate high power from the battery means that less total energy can be extracted than if the same amount of energy was extracted over a longer period of time. Supercapacitors do not have this limitation.

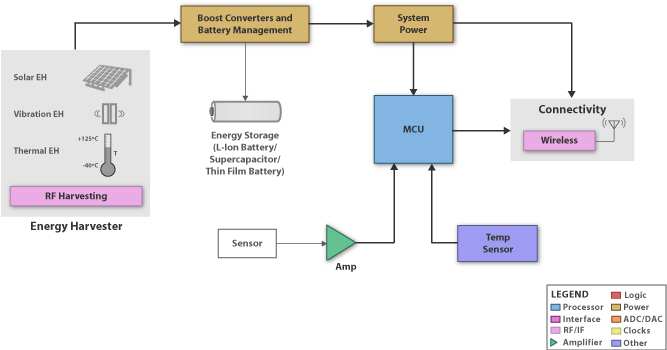

Supercapacitors are used in solar arrays and are also are a good fit for micro-energy harvesting applications, which by definition do not require much energy storage. Milliwatts scavenged from a nearby thermal, vibration, or biological sources can power the sensors used for monitoring and controlling motors. Vibrational energy created by rotating machinery, for example, is stored in the supercapacitor after first being converted to electrical energy by a harvesting device. Using supercapacitors can eliminate the need for replacing batteries or the expense of running a power line to a rechargeable battery. Figure 2 illustrates a block diagram for generic energy harvesting. Although supercapacitors theoretically could be the sole energy source, today’s design practice usually employs a battery to provide energy over the long term and supercapacitors to satisfy peak power demands. Cellergy and others offer devices ideal for these applications.

Micro-harvesting designs benefit from supercapacitor integration

Figure 2: Micro-harvesting designs benefit from supercapacitor integration (Courtesy of Texas Instruments).

The previously mentioned MAX 17710 charger IC can be used in energy harvesting applications. It integrates an input boost regulator so it can handle charges as low as 800 mV. The MAX 17710 can harvest energy from 1 µW to 100 mW. To protect battery/supercapacitor energy storage devices, it limits input source voltages and regulates or shunts excess power. A low-dropout linear regulator (LDO) with selectable voltages of 3.3V or 1.8V prevents overcharging. To learn more about energy harvesting technologies and products, visit http://www.mouser.com/applications/energy_harvesting/

Conclusion

Until recently, supercapacitors were relegated to fairly mundane applications such as memory protection and internal battery backup, but in the last few years the application space has broadened significantly into hybrid vehicles, smartphones, and energy harvesting. New technologies on the horizon promise to bring supercapacitors into full competition with rechargeable batteries.

Advertisement

Learn more about Mouser Electronics