Cambridge-based company Novalia is looking to have technology that can print a keyboard on the market in the next year or so.

Printing presses designed for high-volume runs of things like shampoo bottles, cans, etc., are now starting to create electronics. Novalia wants to update the industry’s current processes to increase its efficiency in this regard; specifically, they instead want to use metal plates with the circuit embossed so as to carry conductive ink.

The Novalia group estimates that electronics can be printed at a rate of about 100m/minute, which is much faster than traditional electronic production, though, a bit slower than what the presses are printing ordinary ink labels.

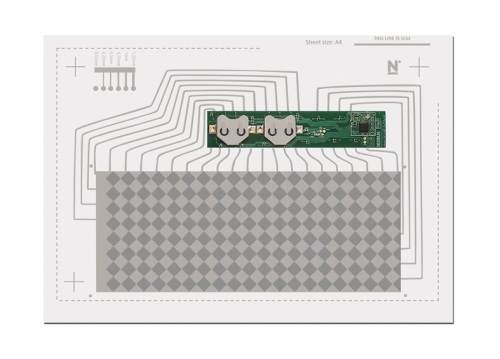

In terms of printing keyboards, both layers of the board would be printed at the same time. While the top layer cannot work without the bottom layer, the underlying matrix can function without the top and be used in the same way as any other capacitive touch screen, including glass, plastic, etc.

The keyboard has Nordic’s nRF51822 ARM Cortex-M0 based processor embedded on the paper to handle both the decoding of the keyboard and transferring the keystroke commands to the keyboard via Bluetooth. While it’s not ideal to attach a single chip to the A4 sheet, Novalia has experimented with printing transistors in the past, but the technology proved too unreliable.

Novalia’s keyboard is powered by two CR2016 watch batteries. The housing that shelters all of the electronics is about .08 inches deep, while the keyboard area can be as thin as 50-microns.

Altogether, the device weighs approximately 30g, and is a tenth the thickness made by other processes. It’s also much cheaper to produce and far more flexible.

Story via theregister.co.uk

Advertisement

Learn more about Electronic Products MagazineNordic Semiconductor