Long before cell phones, the Internet, ICs, and even transistors, some applications required or benefitted from monitoring by multiple sensors. Generally, these early applications required a human to interpret data from separate sensors and instruments and to draw a conclusion on what was happening. A meteorologist might look at the rate of changes observed on weather instruments: a falling barometer, increase in wind speed, and change in temperature — and then make an educated guess as to what the combination of sensor readings meant. That’s not a very sophisticated example, but it demonstrates an example of sensor fusion — multiple types of sensors working together to solve a problem.

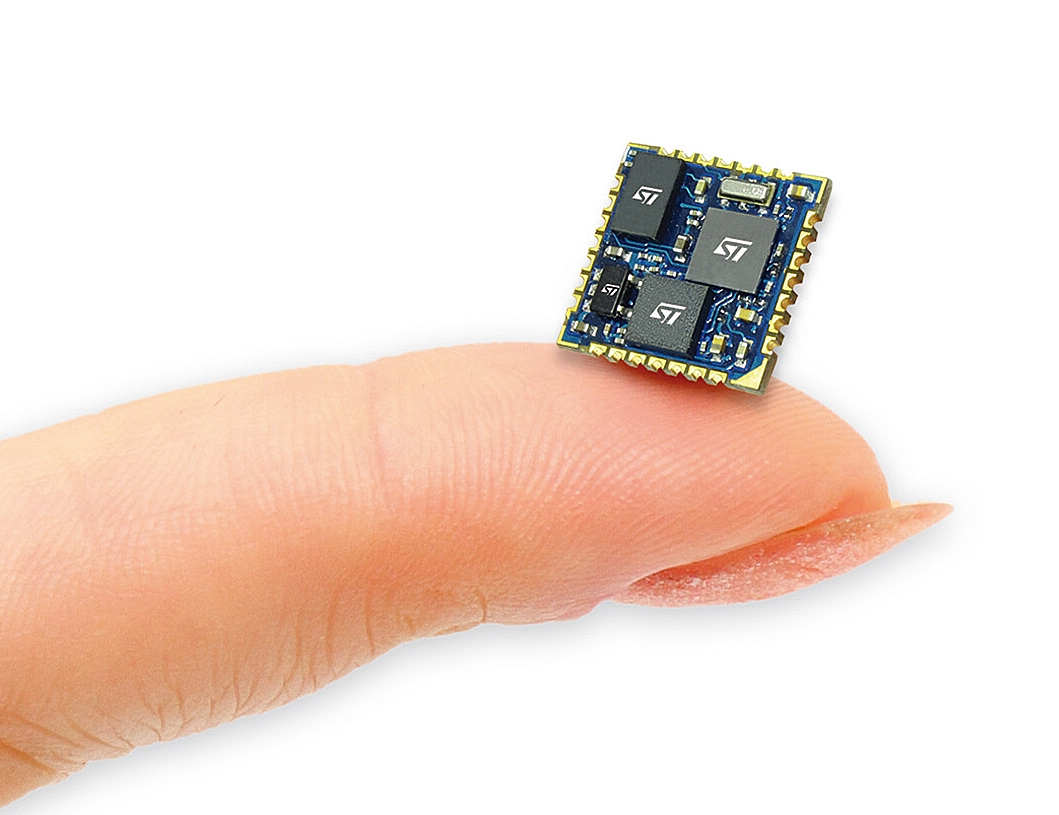

With advances in processor technology, a number of IC manufacturers have taken on the task of doing the heavy lifting to bring sensor fusion to the mass market. With off-the-shelf sensor platforms, sensor hub chips, and fusion algorithms, it is now possible to efficiently interface to a variety of sensors simultaneously. For the most part, the processing is done by a specialized controller chip, which may be identified as an MCU, a sensor hub or a sensor fusion processor. STMicroelectronics’ iNemo family of inertial modules and smart sensors integrate multiple sensors with a 32-bit ARM processor running the iNemo engine sensor fusion suite of algorithms. Similar technology is being applied in the consumer market in smartphones, activity monitors, and other devices.

While quite a lot of functionality can be achieved at a local level, interaction with the Internet of Things is where the fun really begins. Remote sensor data can be processed by a sensor fusion device and sent to the Cloud for recording, further analysis, or even to order an action.

For example, an unattended pump operating in a remote location is always at some risk of failing. A few years ago, a remote sensor may have been in place to identify if it were running hot or had even failed. Now, the same pump can also be monitored for vibration, exhaust chemistry, bearing noise, and the external conditions around it. A predetermined program could empower the sensor fusion controller to shut down the pump or even cycle its operation until a technician can arrive. The system would also know in advance whether it is likely that the entire pump must be replaced or just a component. Here, a sensor fusion solution could eliminate downtime as well as costly emergency service calls, and even collect data to analyze how well the pump is working over time. The same general idea applies to monitoring an aircraft engine in flight, a building elevator, or myriad other mechanical devices.

Sensor fusion is a technology that has come of age, taking advantage of developments in sensors, processing power, wireless communication, and other technologies. Once out of reach of all but the most advanced government labs, the technology is now available off-the-shelf, at prices that even fit the BOM budget for virtually any application.

Now closely linked to mobile technology and the rapid development of lower-cost digital sensors, sensor fusion is poised for explosive growth.

Advertisement