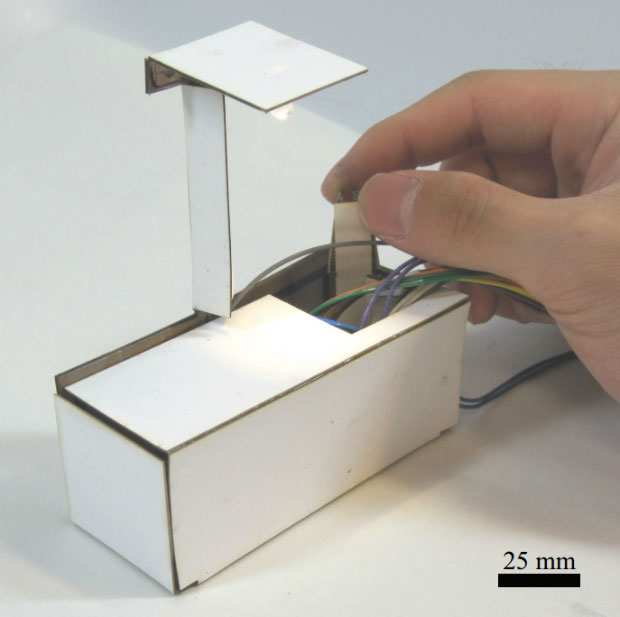

A printable LED lamp has been innovated that folds up, down, and is ready to illuminate your desk. Making its debut at the IEEE International Conference on Robotics and Automation (ICRA) in Hong Kong, this concept has been created by developers from Wyss Institute for Biologically Inspired Engineering at Harvard University. In the past, we’ve seen some impressive inventions like the malleable-circuited robot from researchers. This invention is different, for it contains totally flexible parts that were once impossible to generate through the means of printing.

The self-folding lamp contains a motor, capacitive touch sensor, battery, and is flexible by nature. Nearly all parts, including the wires, were printed out. It is truly remarkable that technology has evolved so quickly as to have adequate applications for printing intricate sensors. Parts like the LED were not printed; they were constructed and bolstered to the device before it folded. The lamp was wired into an Arduino microcontroller to exercise control over the LED’s capacitive touch sensor.

A hinged bar link can be repeatedly twisted in order to open or close the lamp. The lamp’s onboard sensors activate the LED through force or when the user wants to change the lamp’s brightness. The printer used for this project is quite specialized, for it is a layered sandwich of shape-memory heat-enabled polymers that facilitate folding capabilities. Thin layers of copper, paper, and foam provide structure while a double-sided tape keeps holds everything together.

This technology is crucial to the evolution of other projects of a similar nature. For example, when printing other electronics or robots, this printed sensor technology will be of great use. In an academic publication, the Harvard researchers stated:

“ The self-assembling lamp demonstrates the potential for the rapid and inexpensive production of self-folding machines that can interact with the environment. It showed that even complex mechanisms, such as the mechanical switch, can be integrated into the self-folding process of a larger machine, and utilized in practical electronic circuits. Although printable sensors may lack the robust structural strength and reliability of other sensors, they have many potential applications such as low-cost rapid prototyping and manufacturing of customized designs in residential homes. The development of sensors that utilize self-folding manufacturing techniques and their integration into more complex structures is an important stepping stone in the path towards autonomously assembling machines and robots.”

Story via IEEE

Advertisement