NASA seems to love 3D printing– it mustered up some 3D-printed rocket engine parts and 3D-printed pizza makers, but now the space agency is using the 3D-printing craze to create tiny space cameras.

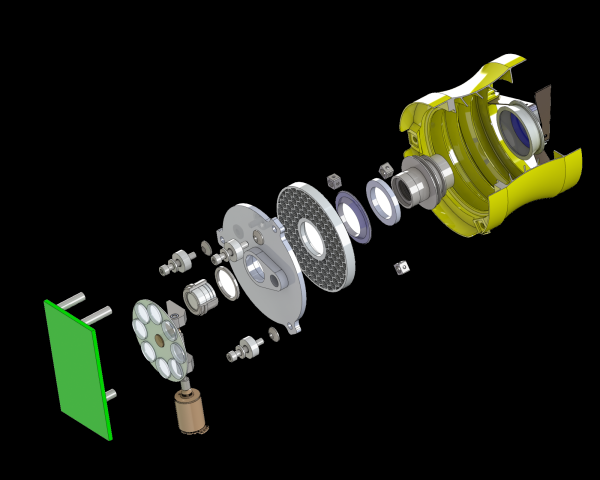

Tiny space camera made of 3D-printed parts will look like this. (Image via NASA)

Tiny space camera made of 3D-printed parts will look like this. (Image via NASA)

“As far as I know, we are the first to attempt to build an entire instrument with 3D printing,” said Jason Budinoff, aerospace engineer from NASA’s Goddard Space Flight Center in Maryland.

The 2-inch instrument is sized for a CubeSat satellite, which is made of units each about 4 inches on a side. It will also come equipped with fabricated mirrors and glass lenses and will undergo vibration and thermal-vacuum testing next year.

Tiny space cameras will be mounted to satellites like these. (Image via NASA)

Tiny space cameras will be mounted to satellites like these. (Image via NASA)

Budinoff is also working on a 14-inch dual-channel telescope which will be more like a typical space telescope.

The instruments are being developed to prove how 3D printing could be used in space exploration and even cut costs and manufacturing time.

How it works

A computer-controlled laser will melt and fuse metal powder in designated locations as indicated by a 3D computer-aided-design (CAD) model. Since the components are built layer by layer it is possible to design internal features and passages that could not be cast or machined using more traditional manufacturing approaches.

The tiny camera will be made of four different pieces composed of powdered aluminum and titanium. If they were to use traditional manufacturing processes the camera would require between five and 10 times the number of parts.

Another plus: The component that helps reduce stray light in telescopes is angled in a pattern that instrument builders cannot create with traditional manufacturing approaches in a single piece.

What else is he trying to prove?

Budinoff also wants to demonstrate that he can use powdered aluminum to produce 3D-manufactured telescope mirrors, which has been a challenge because aluminum is so spongy and therefore difficult to polish. Under his plan, a 3D manufacturing vendor will fabricate an unpolished mirror blank appropriate for his 2-inch instrument. Then he will place the optic inside a pressure chamber filled with inert gas. As the gas pressure increases to 15,000 psi, the heated chamber in essence will squeeze the mirror to reduce the surface porosity — a process called hot isostatic pressing.

Budinoff’s tiny space camera project is set to be complete by the end of September and will undergo spaceflight testing in 2015.

Advertisement

Learn more about Electronic Products Magazine