Mechanical relays have proven themselves as reliable, tough, and robust for a variety of signal- and power-switching applications. Physical contacts using air gaps or spaces make very-high off-state impedances and provide thousands of volts of inherent-electrical isolation. However, mechanical relays are not perfect.

At high voltages, contacts act as spark gaps and can introduce very-high-voltage spikes with very-fast-rise times all at once as opposed to solid-state devices, which soak up over-voltage currents and respond rather quickly to ESD. Another drawback happens at high frequencies where air-gap contacts can act like a feed-through capacitor and couple signals while in the off-state. Also, relays chatter, even the good ones. Sharp mechanical jolts can cause contacts to bounce and make undesired momentary closures. And finally, relays are very slow in switching compared to the speeds possible with solid-state devices.

Addressing many of these concerns, solid-state mechanical relays are faster, insensitive to shock and jolts and can absorb spikes and surges well, especially when combined with transient suppressors and protection circuitry. However, solid-state relays are also more costly, and can exhibit higher on-resistances than desired.

An alternative to both is to create your own solid-state relay using photovoltaic drivers (also called opto-isolators) and FETs. This approach lets you tailor your solution by choosing the components that are the best fit for your specific needs.

Using single FETs creates an effect source or sink for current, and using two back-to-back FETs can create a bi-directional switch that is ideal for AC current and signal waveforms. Single-pole single-throw, single-pole double-throw and even multi-pole types of relays can easily be implemented using a variety of tough, automotive-grade transistors to match the power-handling requirements on hand.

What is particularly nice about this approach is that logic-level signals can typically be used to drive the internal LED inside the photovoltaic drivers. The internal LED, usually IR, charges the optically sensitive gates of the internal photo diodes or photo transistors, which are in series to provide enough photovoltage to keep the switched power devices in the ON state.

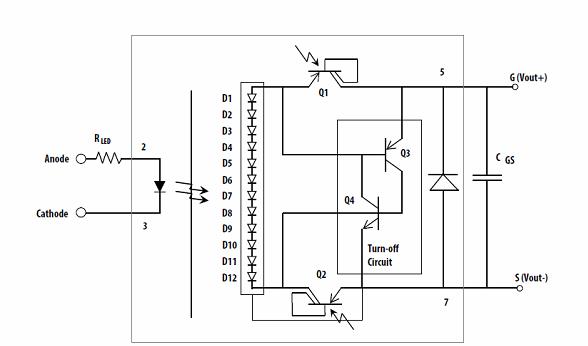

For example, we can look at the Avago ACPL-K30T driver (see figure above), which uses an internal string of 12 photodiodes that generate a typical open-circuit voltage of around 7 Volts when energized by photo energy from the internal LED. Designed to be a MOSFET driver, a minimum of 10 mA of LED current will completely drive the internal LED to full on-state. At input voltages of 0.8 V or less, the driver is completely turned off.

Rated for automotive applications, the ACPL-K30T utilizes proprietary R2Coupler technology that uses reinforced insulation for high-temperature automotive and industrial applications (-40 to +125 degrees C). The 10-to-20 volt VCC range makes it ideal for 12-Volt automotive designs, and it comes with isolation certifications like UL1577 and CSA compliance with tested 5000 Vrms applications for 1 minute.

Design support through Avago describes the use of the Automotive Grade Photovoltaic Driver and Discrete MOSFETs to form an Optically Isolated Solid State Relay. This includes techniques for guarding against false turn-on and turn-off due to temperature effects and leakage currents charging junction capacitors.

The flexibility of the ACPL-K30T is not limited to automotive applications since the selections of FETs can tailor this approach to a variety of industrial, commercial and medical applications where robustness and high reliability are needed.

Advertisement

Learn more about Avago Technologies