A team of scientists from the University of Rochester has been working with lasers to turn ordinary metals into super hydrophobic materials without the need for temporary coatings that are required in most water-repellant surfaces these days.

(Images via J. Adam Fenster / University of Rochester)

(Images via J. Adam Fenster / University of Rochester)

The precise laser-patterning technique creates an arrangement of micro and nanoscale structures to give metals new properties. The technique also ensures that the structures won’t be rubbed off, but instead permanently inscribed into the metals.

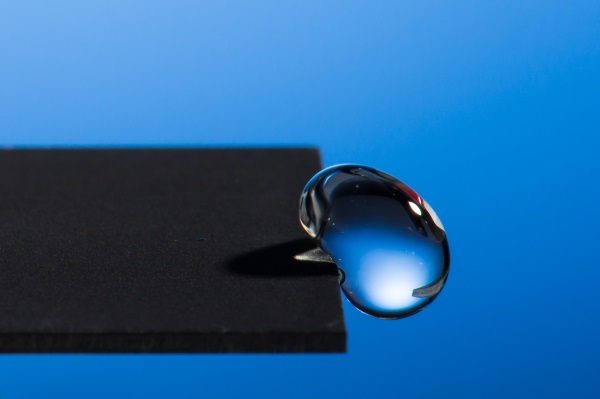

“The material is so strongly water-repellent that the water actually gets bounced off. Then it lands on the surface again, gets bounced off again, and then it will just roll off from the surface,” said Chunlei Guo, professor of optics at the University of Rochester.

Just how water-repellent are these metals?

The material created is much more slippery than the Teflon you would find coated on your nonstick frying pan at home.

Teflon cooking tools are considered non-stick, but not hydrophobic.

Teflon cooking tools are considered non-stick, but not hydrophobic.

(Image via University of Rochester)

Although considered “non-stick,” Teflon pans would not be called “super-hydrophobic” because in order to get the water to roll off one of those pans, you would need to tilt it to almost a 70-degree angle. The materials being created by Guo and his team would need to be tilted less than five degrees in order to achieve this.

In addition to creating super-water-repellent materials, Guo tested the metal’s ability to self-clean. When water bounces off these surfaces, it also tends to collect dust particles.

Water bounces off treated material developed by Professor Guo with lasers.

Water bounces off treated material developed by Professor Guo with lasers.

(Images via J. Adam Fenster / University of Rochester)

In order to test this concept, the team used vacuum cleaner dust and dumped it onto one of its surfaces. Almost half of the dust particles were removed with only three drops of water and only 12 drops to completely clean it. The surface was completely dry after.

To create the material, Guo and the team used extremely powerful, ultra-short laser pulses like the femtosecond laser pulse, which lasts close to a quadrillionth of a second, but during its short burst has the peak power comparable to that of the entire North American power grid.

In the past, Guo’s team worked with these lasers to turn materials hydrophilic, meaning they attract water. The team created a material so hydrophilic that when water touched the surface it seemed to climb upward.

Why we care about super-hydrophobic materials?

Not only can this kind of material play a role in rust prevention and anti-icing, but it also has a potential uses in developing countries that suffer from poor sanitation where bathrooms are difficult to keep clean without wasting water.

“In these regions, collecting rain water is vital and using super-hydrophobic materials could increase the efficiency without the need to use large funnels with high-pitched angles to prevent water from sticking to the surface. A second application could be creating latrines that are cleaner and healthier to use,” said Guo.

The team also wanted to extend the technique to other materials, such as semiconductors and dielectrics, to potentially create water repellent electronics.

Watch the video below for more information about this project.

Funding for the project was provided by the Bill & Melinda Gates Foundation and the United States Air Force Office of Scientific Research.

Learn more at the University of Rochester.

Advertisement

Learn more about Electronic Products Magazine