This post sponsored by Texas Instruments.

Some of the worst abuses of components, boards, connectors, and electromechanical devices occur when testing and debugging. Simple acts such as probing a test point can inadvertently expose low-voltage sensitive inputs to negative voltages, surges, spikes, and shorts. And this is not difficult to do.

While it is ideal to use routed “out-of-the-way” test points, in some instances, that is just not feasible. With such high signal densities and fine pitch connectors, even the steadiest of hand will connect two or more points that should never touch at some point.

Design mistakes can also introduce expensive and time-wasting iterations. It is not difficult to accidentally reverse two signal names on a wiring harness, for example, and when everything is plugged in for the first time, the smoke test actually can yield smoke.

When systems have high voltages, isolated power supplies, and separate grounds, it is usually the test and measurement systems that take the hit. For example, a sensitive front-end in a frequency counter can easily get blown away when the wrong referenced signal is used as a ground. This is compounded with microcontroller development systems that include emulators and probe pins to perform logic analyzer functions. While analog equipment may use sensitive FETs with gates that can easily rupture, digital inputs are also susceptible to failure from stress.

Here is where isolation can help protect front-ends while design engineers abuse their equipment. And let’s face it, we all do.

Bear in mind, however, that isolation is an umbrella term. There are different types of isolation with different characteristics. And there is the need to protect circuitry from a variety of fault conditions. There are specs and standards to adhere to as well, including electromagnetic compliance testing. And, these are changing.

For several decades, the gold standards in isolation were based on the German VDE 0884 specification, which was presented in its finalized form in 1987. Interim specs tried and failed to unify more modern global needs including VDE 0884-10 in 2006 and IEC 60747-17 in 2011. The revisited VDE 0884-10 version 2, which was finalized in 2014, is now under review with IEC for consensus. It significantly improved the inclusion of more updated technologies including magnetic and capacitive isolation. And this is important.

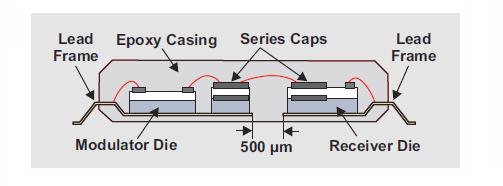

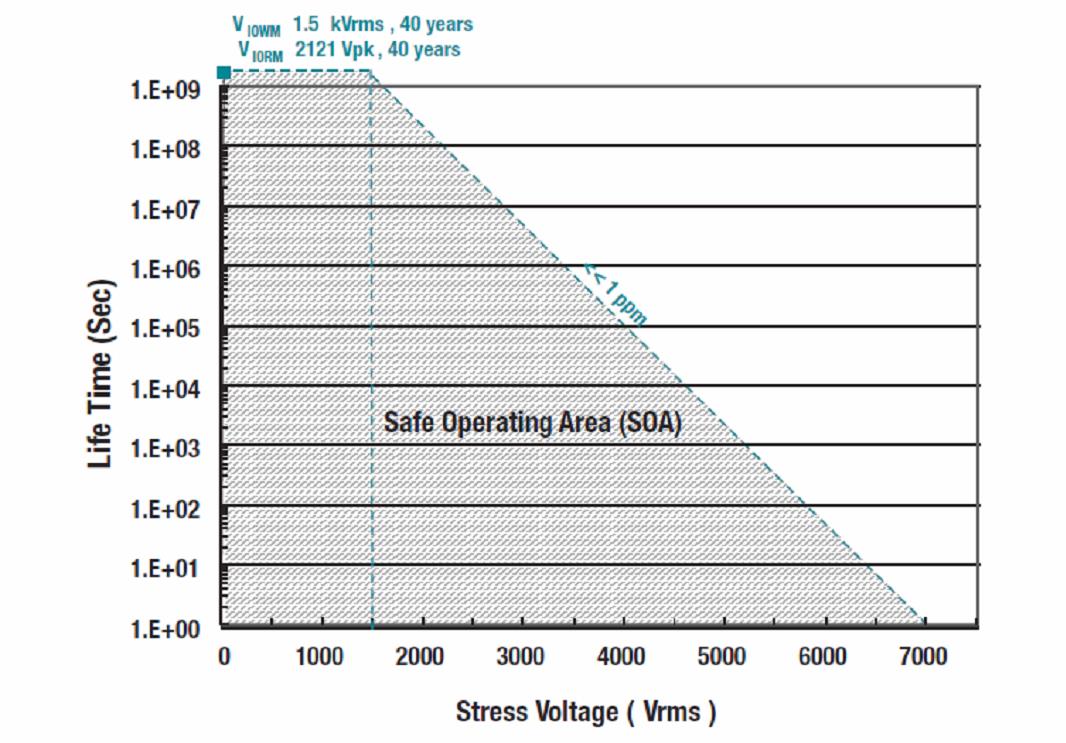

The relatively new series capacitor isolation technology is proving to be rather effective (Fig. 1). Instead of using magnetic or optical techniques, the capacitive approach can more easily be fabbed using standard semiconductor processes making it more likely to be included on more sophisticated chips. They perform well in protecting against high-voltage surges (Fig. 2).

Fig. 1: Substrate-based series capacitor technology can be fabbed in a more standardized fabrication process. Unlike IR emitter/detector processes, this means double-junction capacitive isolation can live on more chips going forward. (Source: Texas Instruments)

Fig. 2: Max working isolation voltage (Viorm) quantifies the ability of the isolator to withstand very high voltages over lifetime. Series capacitor isolation devices excel here. (Source: Texas Instruments)

Older IEC standards included coverage for the newer series capacitor isolation technology. This is no longer the case as of May 2014. All existing certifications for magnetic and capacitive couplers issued based on IEC 60747-5-5 will be reissued based on VDE 0884-10 Ed.1 and later the more rigorous Ed.2.

Fortunately, parts manufacturers are also great sources for learning and understanding. Several articles, blogs, and reference designs can help engineers wade through this field of obstacles.

For instance, an article from Texas Instruments™ on reinforced isolation techniques meeting the highest industrial performance needs can help identify the areas of concern for a variety of designs. Since communication systems have different needs and concerns for isolation, the Isolating high-speed communications blog may also be useful.

Motor control is another area that can benefit from capacitive isolation, and sensing current flow in each phase of a motor’s windings is discussed in the Isolated, Shunt-Based Current Sensing Reference Design. Another motor control isolated-sense technique designers can explore is the use of an isolated sigma-delta modulator.

ISO7842

For more information about this product, click here.

To request a sample, click here.  To buy now at Mouser, click here.

To buy now at Mouser, click here.

ISO7821

For more information about this product, click here.

To request a sample, click here.  To buy now at Mouser, click here.

To buy now at Mouser, click here.

AMC1305M25

For more information about this product, click here.

To request a sample, click here.  To buy now at Mouser, click here.

To buy now at Mouser, click here.

AMC1305L25

For more information about this product, click here.

To request a sample, click here.  To buy now at Mouser, click here.

To buy now at Mouser, click here.

AMC1304M25

For more information about this product, click here.

To request a sample, click here.  To buy now at Mouser, click here.

To buy now at Mouser, click here.

ISO7842-EVM

For more information about this product, click here. To buy now at Mouser, click here.

To buy now at Mouser, click here.

ISO7841

For more information about this product, click here.

To request a sample, click here.  To buy now at Mouser, click here.

To buy now at Mouser, click here.

Author: Jon Gabay, Hearst Business Media

Advertisement

Learn more about Texas Instruments