The beating heart of most electronic systems today is the crystal oscillator. While devices based on microelectromechanical-system (MEMS) technology are definitely making inroads in this application, the low-cost crystal oscillator is still dominant, and it too is an electromechanical device.

Essentially, crystal oscillators are devices in which the oscillator circuit makes use of the mechanical resonance of a piezoelectric material, most commonly a quartz crystal, to create an electrical signal with a precise, stable frequency. The signal thus created is usually referred to as a clock signal and is used to synchronize the operation of the other electronic devices that make up the system.

The piezoelectric phenomenon—the ability of a material to produce a voltage as a result of applied pressure— was discovered by the Currie brothers, Jacques and Pierre, in 1880. The first oscillator to make use of piezoelectricity was built almost 30 years after at Bell Laboratories, using naturally occurring crystals. Widespread growth in the use of radios and the establishment of radio stations in the 20s and 30s led to commercial demand for these crystal oscillators. With the beginning of the digital era in the 1950s, demand increased dramatically, and a commercial process for growing synthetic quartz crystals, also developed by Bell Laboratories, allowed the demand to be met reliably. Synthetic quartz crystals are still the most common basis for oscillators, but polycrystalline ceramics and, as previously mentioned, MEMS are also used.

Putting crystals to work

The frequency at which a quartz crystal resonates depends on size, shape, elasticity, and the speed of sound in the material. When a quartz crystal is properly cut and mounted, it can be made to bend using an electric field; when the field is removed, the quartz generates an electric field as it returns to its previous shape. Supplied with energy and set in motion, the crystal will vibrate at a precise resonant frequency.

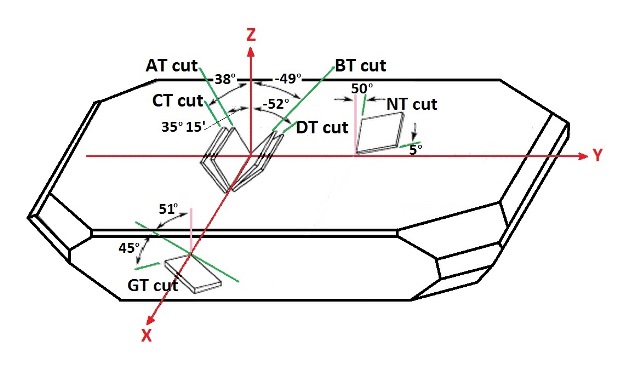

The way in which the quartz crystal is cut determines its resonant frequency (fig. 1 ). Typically, crystals are cut in rectangular slices to produce high-frequency resonance, while for low frequencies the crystal is shaped like a tuning fork. The rectangular slice’s can be made to vibrate in several modes: longituddinal, flextural, and more. The crystal’s specific characteristics will depend on the mode of vibration and the angle at which the quartz is cut relative to its crystallographic axes.

Fig.1: The way in which slice are cut from a quartz crystal will affect its resonant frequency and other attributes. Several common ways of slicing a crystal and the names of the cuts are shown here. The use of “T” in the cut's name indicates high temperature stability.

Depending on the cut, quartz has the advantage that its frequency can be little affected by temperature, so an oscillator will tend to remain accurate. For critical applications the quartz oscillator can be mounted in a temperature-controlled container, referred to as an oven, and shock absorbers added to prevent affects from external mechanical vibrations. Adding capacitance or inductance across a crystal can be used to adjust the crystal’s oscillation frequency.

Ways of resonance

Quartz crystals have two basic modes of resonance, series and parallel, with the series resonance frequency a few kHz lower than the parallel resonance frequency. Crystal manufacturers normally cut and trim their crystals to have a specified resonance frequency when a specific load capacitance is added to the crystal.

Below 30 MHz, crystals generally operate between the two modes, making it appear as an inductance that forms a parallel resonant circuit with an external capacitance connected in parallel. Adding a small additional capacitance in parallel with the crystal will therefore pull the frequency downwards. Adding a capacitor in series with the crystal has the effect of raising the frequency. This capability lets users trim the oscillating frequency of the crystal within a narrow range.

Above 30 MHz , crystal usually operate in series resonance. In this mode, the impedance is at its minimum and equal to a series resistance. For these crystals, the series resistance is specified (

Turning crystals into oscillators

A crystal oscillator circuit sustains oscillation by taking a voltage signal from the quartz-crystal resonator, amplifying it, and feeding it back to the resonator. A resonator has two electrically conductive plates, with a cut crystal sandwiched between them. To begin the oscillation, a control circuit creates a field that places the crystal in unstable equilibrium. With positive feedback in the system, any signal will be amplified and increase oscillation. The resonator acts like a frequency filter, only passing a very narrow range of frequencies centered on the crystal’s resonant frequency.

Quartz crystal oscillators have very low phase noise. Since the crystal mostly vibrates in one axis, only one phase is dominant. Thus they can produce very stable signal. However, environmental factors — temperature, humidity, pressure, and vibration — can influence crystal’s resonant frequency. To reduce the impact of these factors manufacturers have developed temperature-compensated, microprocessor-controlled, and ovenized crystal oscillators (TCXO, MCXO, and OCXO, respectively) to provide high stability.

Performance over time

The stability of a crystal oscillator is given by its Q factor; the higher the Q factor, the more stable the device. A number of influences, collectively referred to as aging, can limit the long-term stability of crystal oscillators. Due to aging, without constant adjustment it is difficult to keep even the best quartz oscillators within one part in 1010 of their nominal frequency.

The gradual change of frequency with time is due to many factors: stresses built into mountings and contacts may relax over time; contaminants can be adsorbed on the crystal surface, changing its mass; crystal composition can be gradually altered; its lattice can be damaged by radiation, and more.

Minimizing the effects of aging is largely a matter of extreme care in the selection of materials and components used in creating the oscillator, the packaging methods, and the manufacturing techniques. Fortunately, aging decreases logarithmically with time, and the greatest changes occurring during the oscillator’s initial life. Thus manufacturers typically artificially age a crystal by prolonged storage at 85 to 125°C to increase its long-term stability.

The good news is that crystals have no inherent failure mechanisms; some have operated in devices for decades.

Advertisement

Learn more about Electronic Products Magazine