A team of chemists and researchers at the University of British Columbia has developed a new way of making state-of-the-art energy storage materials using an inexpensive heat lamp bought at a local hardware store.

The goal of the group’s project was to see if there was a better way to make a coating that could be painted on to a surface for the purpose of either conducting electricity, or converting electricity in to hydrogen cells.

This sort of material is normally made using expensive tools and materials, but the team wanted to develop a technique that allowed them to use a normal heat lamp, and still produce the same results.

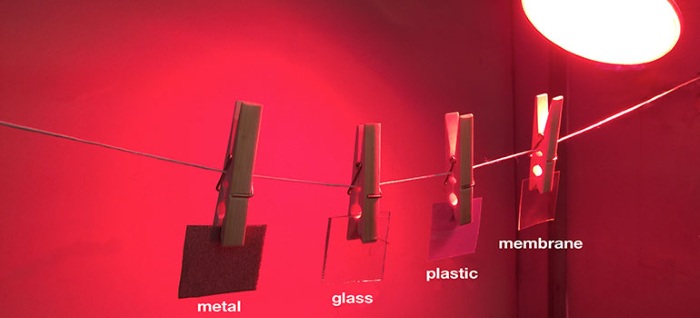

The result of their efforts was the creation of a material which, when painted on to a surface and warmed using a consumer-grade heat lamp purchased at a local hardware store, formed into a catalytic coating.

For those unfamiliar, these coatings are used in a bevy of technologies, including flexible electronics, and systems, like converting electricity in to hydrogen fuel cells. The group’s solution could have major implications on the future design plans of consumer electronics and clean energy technologies.

“Solar farms and wind turbines don't provide a constant supply of energy,” explains study co-author Curtis Berlinguette, an associate professor in UBC's Departments of Chemistry and Chemical and Biological Engineering. “Storing electrical energy produced during times of low demand as hydrogen fuels enables that electricity to be used later during peaks of higher demand. The catalyst coatings we can now produce more easily could help make this process cheaper and more efficient.”

The group’s approach could also help reduce the costs of making catalyst-coated electrodes in commercial applications (e.g. electrolyzers).

“The technique is scalable and amenable to large-scale manufacturing,” says Danielle Salvatore, a chemical engineering graduate student and the paper's lead author.

“We can create these materials on any surface without an expensive precursor,” according to Berlinguette, as he explained that these findings build on earlier work of using more expensive UV light to create catalytic films.

Learn more about the group’s solution via the video below:

The UBC study was published in the new journal, Science Advances. You can read it here.

Advertisement

Learn more about Electronic Products Magazine