BY HANNES BIRK,

Marketing Manager 3D magnetic sensors,

Infineon Technologies AG

Neubiberg, Germany

Magnetic sensors are a workhorse technology for contactless measurement and position sensing applications in automotive and industrial systems. As with all silicon based devices, increasing integration across product generations has led to both greater functionality and to simpler, more robust system designs. The resulting opportunity for product innovation driven by more sensing capability at a lower cost is good news for design engineers.

A Hall sensor element detects magnetic field flux in the direction oriented perpendicularly to the surface of the chip in which it is embedded. Using conventional Hall devices to establish a position in 3D space (x,y and z coordinates) thus requires at least two separate sensors: For example, a differential Hall (two sensors on one chip) used to establish x,y coordinates and an independent single Hall device positioned at right angles. This in turn requires precisely engineered placement and calibration of the multiple sensing elements. This level of complexity, as well as the required physical space to implement a multi-device magnetic 3D sensor, means that engineers face a trade-off when evaluating 3D position sensing technology. For many cases, either mechanical, optical or a combination of mechanical and optical technology meets design requirements within the bounds of a cost-benefit analysis.

Enter the 3rd dimension

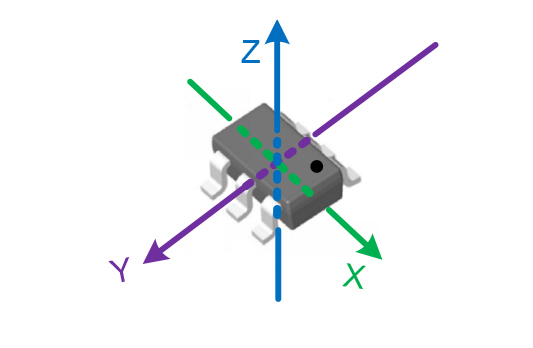

The equation is changed when the classic magnetic Hall sensor is fabricated with both vertical and horizontal plates on a single chip to enable 3D field sensing (Figure 1 ). The vertical Hall plates are sensitive to planar oriented field components from the x- and y- direction, while the horizontal Hall plate is sensitive to the perpendicular (z-direction) oriented field component.

Fig. 1: A classic magnetic Hall sensor is fabricated with both vertical and horizontal plates on a single chip to enable 3D field sensing.

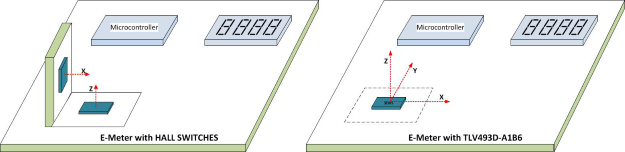

Infineon offers an energy sipping Hall-based sensor with five selectable power modes (Figure 2 ) in a small 6-pin package for magnetic field detection in x, y, and z-direction for reliable measurement of three-dimensional, linear and rotation movements. Applications include joysticks, control elements such as multifunction knobs in white goods, and tamper detection/prevention in electric meters.

Fig. 2: An energy sipping Hall-based sensor with five selectable power modes is offered in a small 6-pin package for magnetic field detection in x, y, and z-direction.

A rich field of applications

In a typical current transformer electric meter, which measures energy based on the voltage and current flowing between two terminals, a powerful permanent magnet placed on the exterior of the meter can render the current sensor useless. The conventional approach to implement magnetic sensing for tampering protection is based on two Hall sensors (one soldered on the related PCB and another one vertical to it on a separate small PCB). The challenges in implementing this approach include the complexity of mechanical construction, calibration and tuning – which increase cost – and the higher power consumption of a multi-device solution. A single 3D magnetic sensor addresses these challenges, bringing large field range, high resolution and temperature measurement with no additional components.

In many consumer products – including computing peripherals and white goods – magnetic sensors replace mechanical and optical solutions. The magnetic sensor is more accurate in covering a wide range of motion compared to mechanical devices. For optical sensing, the challenge is not range of motion but the line-of-sight requirement.

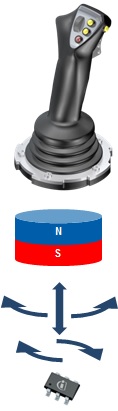

Joystick design has evolved across several decades from four mechanical switches to a pair of potentiometers. An even more simplified design, combined with exceptional ruggedness in harsh operating environments and the long-life of a contactless design, is achieved with a 3D magnetic sensor. This approach is used extensively for machine control joysticks in industrial settings. The latest generation 3D sensors, operating at 3.3 kHz (3,300 measurements per second with power draw of 3.7 mA), yield both precise and lightning fast control at a cost suitable for mass market gaming systems (Figure 3 ).

The latest generation 3D sensors, operating at 3.3 kHz (3,300 measurements per second with power draw of 3.7 mA), yield both precise and lightning fast control

For the ubiquitous multi-function knobs found on consumer white goods, 3D magnetic sensors dramatically alter design considerations. Multiple switches and a photo sensor-based rotary encoder, implemented on several stacked PCBs, are replaced by a sensor and magnetic elements.

In summary, the flexibility provided by Hall-based 3D magnetic sensors makes the technology an excellent candidate to replace potentiometer and optical solutions, and to simplify existing magnetic position sensing design. The designer should consider such factors as linear measurement range, effective resolution (accounting for noise in some readings), bus data rate and ease of integration in a microcontroller-controlled system, stability over the operating temperature range and power consumption profile. For automotive applications, AEC Q-100 qualification must also be part of the design checklist.

Advertisement

Learn more about Infineon Technologies