What are printed circuit boards (PCBs)?

Printed Circuit Boards, also referred to as PCBs, are a part of nearly every electronic device we as consumers own and as a result, are hugely important. These circuit boards allow large amounts of information to be exchanged from components housed both on the board and elsewhere.

What makes up a printed circuit board?

It’s safe to say that PCBs are not only taken for granted but little is known about them by consumers. There are many different material, etching, and layer types that PCBs are composed of, so we’re going to take a look at what makes up a PCB and why these make our electronic world go round.

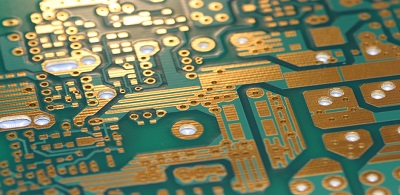

The first thing you notice about a PCB is that it looks like a chaotic bunch of little copper or gold roadways traveling throughout the board. And that’s not far off from the truth, as data and electricity is traveling throughout the board similar to cars on a highway. There is a method to the mayhem, though, as each board was created from a carefully planned schematic.

Material Types

After you have a schematic you will need to choose which material to make the PCB out of. The two most common are fiberglass and phenolic. While the latter is cheaper than the former, both allow boards to be created in varying thicknesses between .8mm and 1.6mm, depending on the amount of layers needed.

Layer Types

The number of layers on a PCB depends on what the board will be used for — generally speaking, there are three types for varying needs.

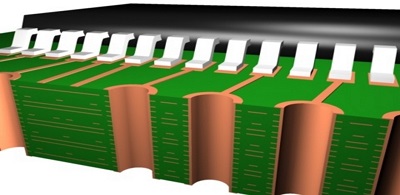

The three types of layers are: Single, Double, and Multiple. The Single layer consists of just one layer of copper, the double layer consists of a layer of copper on either side of the PCB, and the Multiple is layered like a cake. Each layer is made using either an additive or subtractive process. The additive process plates the substrate with copper in the desired design, while the subtractive process plates the whole substrate and then etches away the areas that are not part of the design.

Depending on layer type, there are holes that are drilled in the PCB according to the design that allow power to pass from one side of the board to the other.

Conclusion

Each and every board has a specific purpose depending on application and the evolution of the PCB has allowed us to enjoy some technological marvels! As technology progresses we will likely witness many more amazing circuit board manufacturing techniques.

Author

Aaron LaBarbera

Related articles

Advertisement

Learn more about Electronic Products Magazine