Researchers at the Georgia Institute of Technology have figured out how to put a liquid cooling system onto the computer chip. Should their solution prove scalable, it could introduce a whole new class of denser electronics.

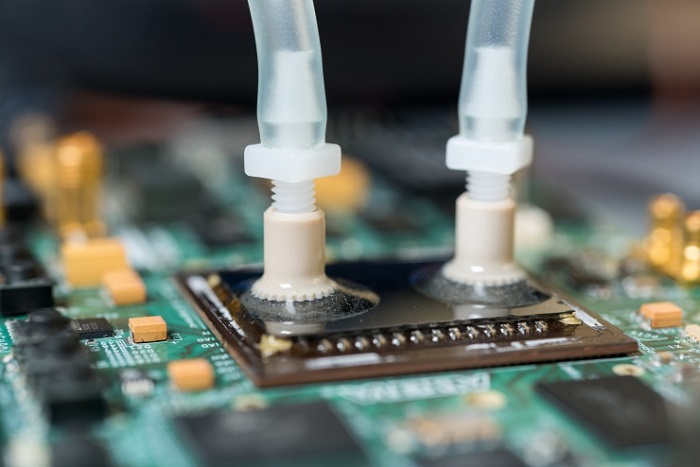

In order to accomplish this feat, the team cut microfluidic passages right into the backsides of production field-programmable gate array (FPGA) devices. Doing this, they found, allows for liquid cooling to occur where it’s needed most — right where the transistors are operating.

Taking a closer look, the team used a 28-nanometer FPGA device made by Altera and demonstrated a monolithically-cooled chip that can operate at temperatures more than 60% below those of similar air-cooled chips. Along with improved processing power, this lower operating temperature also means longer device life and less current leakage.

“We have created a real electronic platform to evaluate the benefits of liquid cooling versus air cooling,” said Sudhakar Yalamanchili, a professor in the Georgia Tech School of Electrical and Computer Engineering and one of the research group's collaborators.

Cooling occurs due to the simple de-ionized water that flows through microfluidic passages which, it’s worth pointing out, entirely replaced the air-cooled heat sinks and heat-spreading materials normally placed on the backs of chips.

“We believe we have eliminated one of the major barriers to building high-performance systems that are more compact and energy efficient,” said Muhannad Bakir, an associate professor and ON Semiconductor Junior Professor in the Georgia Tech School of Electrical and Computer Engineering. “We have eliminated the heat sink atop the silicon die by moving liquid cooling just a few hundred microns away from the transistors. We believe that reliably integrating microfluidic cooling directly on the silicon will be a disruptive technology for a new generation of electronics.”

Existing liquid cooling technology removes heat using cold plates that are externally attached to fully packaged silicon chips — adding thermal resistance and reducing overall heat-rejection efficiency.

The Georgia Institute of Technology solution involves etching cooling passages into the silicon and incorporating silicon-based cylinders approximately 100 microns in diameter to improve heat transmission into the liquid. Next, a silicon layer is placed over the flow passages, and ports are attached for the connection of water tubes.

During several rounds of tests, including a demonstration for the DARPA officials who are supporting the team’s research into the technology, a liquid-cooled FPGA was operated using custom processor architecture. With a water inlet temperature of about 20 degrees Celsius and an inlet flow rate of 147 milliliters per minute, the device operated at a temperature of less than 24 degrees Celsius, compared to an air-cooled device that operated at 60 degrees Celsius.

“This may open the door to stacking multiple chips, potentially multiple FPGA chips or FPGA chips with other chips that are high in power consumption. We are seeing a significant reduction in the temperature of these liquid-cooled chips.”

Worth noting is the reason why the team chose to work with FPGAs — they provide an ideal platform for testing out different circuit designs. Also, FPGAs are common in many market segments (including defense, hence DARPAs interest); they can also be used to cool CPUs, GPUs, and other devices like power amplifiers.

Along with providing a better cooling system, this solution could reduce hotspots in circuits by applying cooling closer to the actual power source. What’s more, by eliminating the heat sink, engineers can design much more compact packaging for electronic devices.

“We have reached an important milestone that we hope to use as a stepping stone to reach other objectives,” said Bakir. “There is still a big challenge ahead, but we expect this to allow much denser, higher-performance computing systems that will dissipate less power. We can think of many interesting applications for these cooling technologies.”

Altera's principal investigator for the project, Arifur Rahman, said: “Future high-performance semiconductor electronics will be increasingly dominated by thermal budget and ability to remove heat. The embedded microfluidic channels provide an intriguing option to remove heat from future microelectronics systems.”

The team presented their study, entitled “Embedded Cooling Technologies for Densely Integrated Electronic Systems”, at the IEEE Custom Integrated Circuits Conference in September 2015.

Via the Georgia Institute of Technology

Advertisement

Learn more about Electronic Products Magazine