Image credit: Jens Bauer / Karlsruhe Institute of Technology.

Image credit: Jens Bauer / Karlsruhe Institute of Technology.

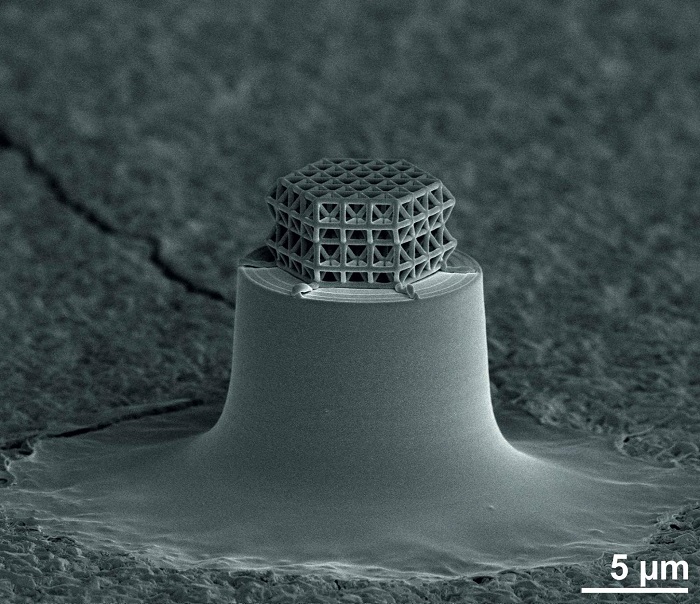

Using the established 3D laser lithography process called “two-photon direct laser writing” (enables printing resolutions on the order of hundreds of nanometers), scientists at Germany’s Karlsruhe Institute of Technology have created the world’s smallest lattice, with single struts shorter than 1 μm and diameters as small as 200nm.

For the experiment, Dr. Jens Bauer, lead author of a paper published online in the journal Nature Materials, said he and his colleagues started off by manufacturing three differently sized lattices with tetrahedral unit cells with edge or strut lengths of 10, 7.5 and 5 µm.

The team then baked these polymeric microlattices into carbon nanostructures using a furnace.

“The objects were exposed to temperatures of around 1,650 degrees Fahrenheit (900 degrees Celsius) in a vacuum tube furnace,” Dr. Bauer and co-authors explained.

“During the pyrolysis, the unit cell sizes of our structures shrank by roughly 80% compared to the initially fabricated sizes, yielding lattices with unit cell edge lengths of 2,020 nm, 1,440nm and 970 nm, respectively.”

“The struts of the pyrolyzed lattices have elliptical cross-sections with axial diameters of 330, 270 and 225 nm and lateral diameters of 275, 235 and 205 nm, respectively, for the three different lattice sizes.”

Knowing they had just created something the world’s never seen before, the researchers went ahead and began testing the structures for stability under pressure.

“According to the results, load-bearing capacity of the lattice is very close to the theoretical limit and far above that of unstructured glassy carbon,” said team member Prof. Oliver Kraft.

“The strength-to-density ratios of the nanolattices are 6 times higher than those of reported microlattices. With a honeycomb topology, effective strengths of 1.2 GPa at 0.6 g/cm3 are achieved,” the scientists said.

Putting this into perspective, the nanolattice has a density of .6g/cm3 while being able to withstand a pressure of 1200 N per square millimeter — this means that while the material is as light as some foam, it is a thousand times stronger; a thoroughly impressive tolerance for high pressure stress.

“Diamond is the only bulk material with a notably higher strength-to-density ratio,” the team points out (while diamonds only have a 60 GPa ultimate tensile strength, they have a density of 3.5 g / cm3, so the material’s strength-to-weight ratio is better).

To learn more about the manufacturing process, download the group’s paper, entitled Approaching theoretical strength in glassy carbon nanolattices.

Via Sci-News.com

Advertisement

Learn more about Electronic Products Magazine