By RICHARD COMERFORD, Senior Technical Editor

Electronic Products

www.electronicproducts.com

Based on MEMS technology, a new class of temperature-compensated “crystal” oscillators, or TCXOs, is coming to market. Called Super-TCXOs, they are the smallest and most accurate low-power/low-frequency timing solutions available to date. Key to their significance is that they provide ultra-small size at low frequencies, ranging from 1 Hz to 1 MHz, including the essential 32 kHz. While Super-TCXOs are primarily used to improve timing accuracy in systems, they can also replace one or more quartz-based devices and improve area, component costs, and power.

Today’s clocking needs

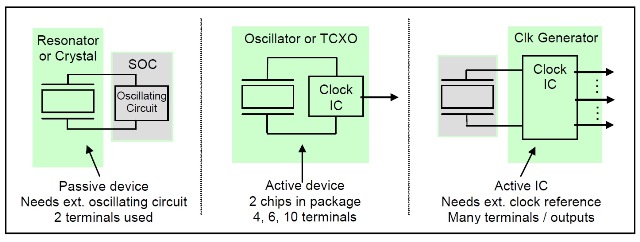

In general, a TCXO is a temperature-compensated oscillator. Compared to a resonator/crystal or a clock generator, an oscillator comprises both the resonator and oscillator circuitry within one device (Fig. 1 ). Today, quartz crystals are not available in low frequencies in very small packages and, therefore, aren’t suited for small, battery- operated products, which use low-frequency clocks. Yet the rapidly emerging Internet of Things (IoT) and wearable segments are the perfect applications for a precision 32-kHz reference clock. For example, the typical wearable application has a tiny battery (typically

Fig. 1: Both active and passive devices are needed to create a complete oscillator, or TCXO.

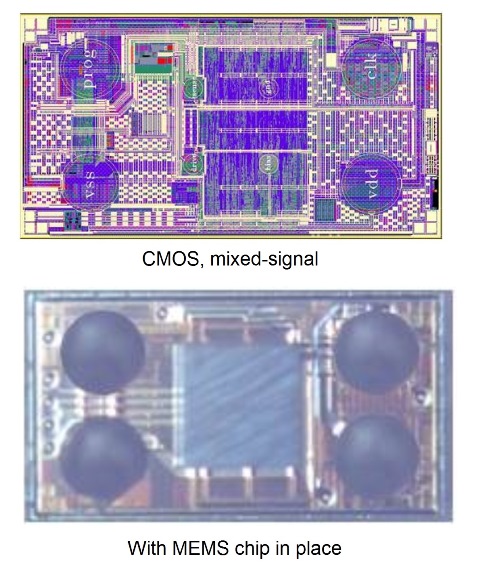

Small size is an inherent advantage of MEMS-based oscillators. In quartz crystal technology, physics dictates that the lower the frequency, the larger the crystal resonator. However, MEMS resonators do not have the same constraint. A typical die size of SiTime’s MEMS resonator is 0.4 x 0.4 mm, and its mass is 1/3,000th that of a typical quartz crystal resonator. Because SiTime’s MEMS resonators (see “The first Super-TCXOs,” opposite ) are fully encapsulated in silicon and manufactured in CMOS fabs, they can be packaged using modern technologies, including wafer-level chip scale packaging (WLCSP).

A key advantage of an ultra-stable (±5 ppm) Super-TCXO is its ability to turn the wireless interfaces ON and OFF more precisely than a quartz device can, minimizing the ON time of the wireless interface and thereby extending battery life. The Super-TCXO can thus take on various timekeeping functions, such as a reference for a real-time clock (RTC) or audio subsystem, as well as a so-called sleep clock for common connectivity interfaces (for instance, Bluetooth, Bluetooth Low Energy or BLE, and WiFi).

Wearables, for example, typically need two 32-kHz reference clocks: one for the BT/BLE chip’s sleep clock and one for the MCU/SOC’s RTC. Because Super-TCXOs are active components, they can easily drive two loads — something a resonator cannot do. Therefore, one Super-TCXO can replace multiple quartz XOs or XTALs, reducing the bill of materials (BOM) while saving space and cost. The active TCXO’s high drive capability also means it can provide placement flexibility on a space-constrained board.

Sleep and accuracy

The sleep clock — a key to saving power in today’s low-power portable devices — is the reference clock that runs while the rest of the system is idle, hibernating, or turned OFF. The ideal sleep clock frequency is 32 kHz because it consumes the least amount of power and is easy to electronically divide to one second for timekeeping purposes. Consuming the least amount of power is particularly significant because most systems require that this reference clock always run. It is needed to drive the system RTC so it can track time, and, in systems that include wireless connectivity, the 32-kHz sleep clock is used as the low-power reference clock when the wireless subsystem (e.g., Bluetooth, BLE, WiFi) is not operating.

Having an accurate sleep clock is particularly important. During a connected state, wireless subsystems operate in a cyclic sleep scenario to save power, periodically waking to receive pings from the central or master system. To wake up at the precise time, the peripheral wireless device relies on the accuracy of the 32-kHz sleep clock. Due to inherent inaccuracies of the master and slave sleep clocks, the peripheral device must wake up earlier, to avoid missing the ping from the master. During this early ON time, power is consumed, causing a power penalty. Therefore, using a highly accurate Super-TCXO (±5 ppm compared to traditional quartz crystals’ 180 to 200 ppm) can enable longer sleep time and save significant system power.

Integrality

The ability of a component to become part of the whole — its integrality ability, if you will — is essential to its application in today’s highly integrated electronics. Wearable, IoT, and mobile products are examples of applications that are driving miniaturization, which is achieved, in large part, by modularization of subsystems. Modules in a mobile phone include power management (PMU, μDC-DC converter), RF/FEM power amplifier, storage/SSD, and connectivity (BLE, WLAN) modules; each can shrink in size by about 35 to 90% through modularization.

Because they are composed of two all-silicon die in a chip-scale package, Super-TCXOs can be over-molded and integrated into a system-in-package (SIP) module. Furthermore, Super-TCXOs with in-system auto-calibration can compensate for frequency errors induced by board-level stresses during assembly, reflow, under-fill, and/or over-molding.

Initially, Super-TCXOs are calibrated (trimmed) over multiple temperature points to guarantee extremely tight stability over –40°C to +85°C with an active temperature correction circuit. In addition, after the system is assembled and the pc board is ready for production test, the Super-TCXO can be auto-calibrated during final system test. To do so, a GPS-disciplined, precision 10-MHz clock is applied to the Super-TCXO. Its clock is compared to the precision 10-MHz clock, and the resulting error is removed. Auto-calibration typically takes two to five seconds, which occurs in parallel with the rest of the production system test. After auto-calibration, the typical frequency offset is less than ±5 ppm.

The first Super-TXCOs

The first of the Super-TCXOs — the SiT1566, SiT1568, and SiT1576 32-kHz oscillators from SiTime (www.sitime.com) — are available in a 1.5 x 0.8 x 0.6-mm package. That gives them a footprint of a mere 1.2 mm2 — up to 85% smaller than quartz products — and makes them up to 40% thinner. In addition, the MEMS-based oscillators’ use of TempFlat MEMS technology lets them deliver an accuracy of ±5 ppm over an operating range of –40°C to 85°C, enabling chronometer-grade timekeeping and the longest battery life. One of the devices, the SiT1568, also offers an innovative, in-system, auto-calibration feature that lets customers eliminate timing inaccuracies introduced by stresses during system assembly, reflow, under-fill, and over-molding. The SiT1576 is also programmable over a range from 1 Hz to 1 MHz.

All devices have a programmable temperature-sensing update rate that, in industrial and mobile applications, maintains dynamic and overall stability in the presence of fast thermal gradients. The MEMS ICs can drive multiple loads to reduce the number of components required. Aging is ±1.5 ppm for the first year (twice as good as quartz devices), start-up time is 300 ms (65% faster), and their jitter performances enable support of audio applications. Samples are available now, production quantities in Q2 2016.

Advertisement

Learn more about Electronic Products Magazine