At Apple’s spring product launch on March 21, 2016, the company unveiled its super-secret 29-armed robot that works to tear apart iPhones. Deemed Liam, the robot is a large-scale, freestanding device that occupies almost the entire width of Apple’s warehouse facility and has been three years in the making.

While most assembly-line robots work to put products together, Liam helps to disassemble ruined and returned iPhones. Before revealing the robot at Apple’s event, only a few of its employees knew of its existence.

For iPhone 6S users who trade in their devices at Apple retail stores, the ones that have suffered from liquid damage are shipped to one of two distribution centers in the United States. There, the devices are manually inspected, and then those with salvageable components are shipped to Apple’s secret warehouse to have Liam break them down.

Apple’s concept behind Liam is that since the company assembled the iPhone originally, who better to take it apart than the maker itself? With Liam, the smartphone giant is addressing a growing issue for the consumer electronics industry: waste, specifically from batteries, is an increasing hazard in developing nations. Creating recycling programs is a significant way in which the U.S. can help the problem, especially as consumer demands for greener products grow.

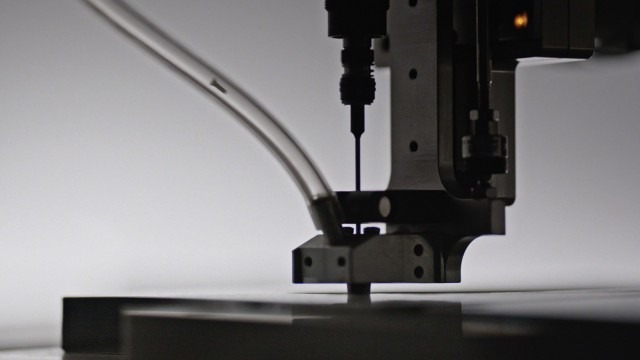

Liam is programmed to carefully disassemble several pieces of returned iPhones, including SIM card trays, batteries, and cameras, removing the parts bit by bit, making it easier to recycle. The robot separates the components of the iPhone with robotic precision, assuring that no pieces of glass and plastic will be mixed in with copper.

Where the name came from is nothing more than a simple response from Apple: the robot looked like a “Liam” and it stuck. Its large stature resembles a traditional horizontal assembly line, making the standard hum from motors and moving parts, accompanied by clanks of the components dropping into containers.

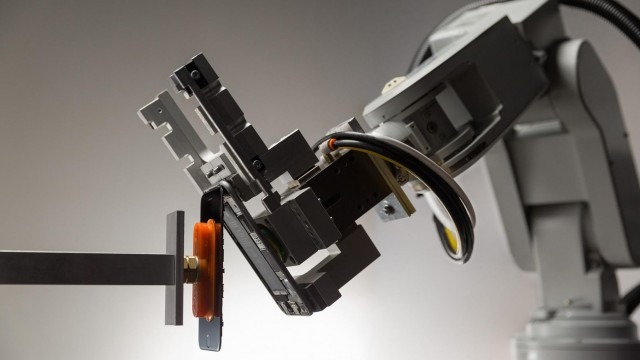

While Liam is composed of the entire system, the 29 robotic helpers do the handy work; some have drills, while others have screwdrivers and suction cups. A warehouse worker puts approximately 40 iPhones onto a conveyor belt at a time, and then the process begins.

The first robot removes each iPhone’s screen from the back casing, where the pieces are transported via the conveyor belt to another section where the battery is removed. While batteries can be damaged or punctured during disassembly, Liam has the removal down to a science. Other pieces are collected using various methods: The screws are sucked up into small tubes and are dropped in a nearby container, while SIM card slots are dropped into a small bucket below the system. If there is a problem removing the component or an issue with the battery’s temperature being too high, a small tablet display notifies with a “failed attempt” message.

At some stations, robots work in pairs; if a screw takes five tries to remove, another robot will be free to move on to another task on the same device. The process is optimized so that if one robot breaks down, the entire procedure can continue for roughly 30 minutes until a backup occurs.

Liam can completely disassemble an iPhone every 11 seconds, with dozens going through the system at all times. Approximately 350 devices are turned around every hour, meaning roughly 1.2 million iPhones per year.

Currently, Liam is put to work Monday through Friday, with weekends off. Apple also noted that the project is still undergoing development and research to make it even more efficient.

Source: Mashable

Advertisement

Learn more about Electronic Products Magazine