Hyperloop One, a start-up competing to realize Elon Musk’s vision of the high-speed Hyperloop transportation system, held its first public demonstration this past Wednesday, May 11th . The company showcased the engine components that it’s been secretly designing to rocket people and cargo at hundreds of miles per hour through vacuum tubes.

The company conducted what it called a “Propulsion Open Air Test” at a test site located in an industrial park in the city of North Las Vegas. Those present had the opportunity to witness the culmination of three years of research & development as the ultra-fast vehicle accelerated at up to 400 miles an hour within just a few seconds, making its way across a short track in the desert before coming to a complete stop in a bed of sand.

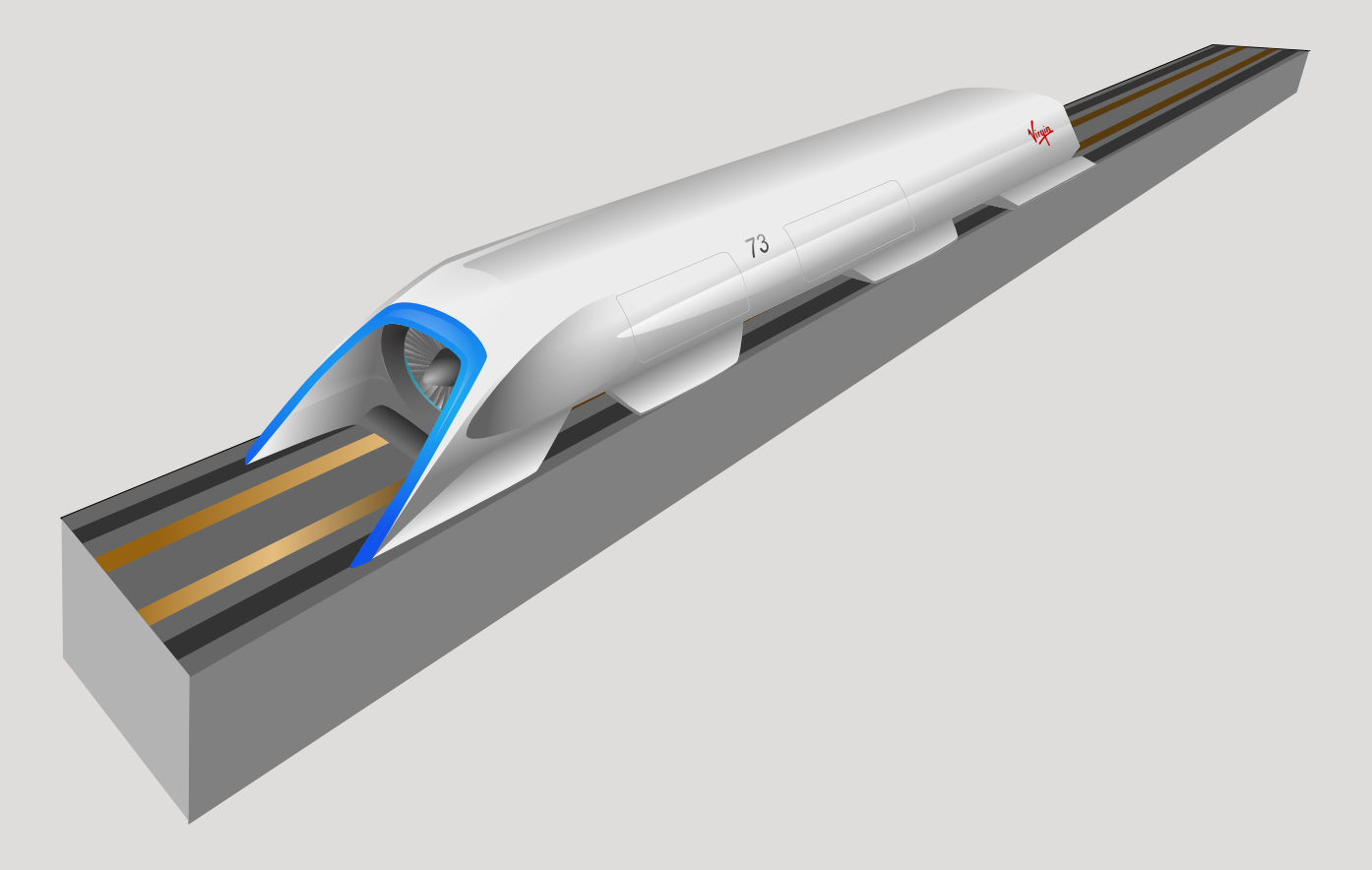

In the long-term, Hyperloop One hopes to create a low-cost transportation network that moves at near-supersonic speeds with minimal passenger disturbance, likening the G-force exhibited on the passenger to no more than that of an airplane taking off. The technology demoed in Nevada focused entirely on acceleration, thus forgoing the near-vacuum tube and passenger/cargo pod. Instead of the pod, a sled bracketed to the rail was propelled by the magnetic force generated by stators, or motors set along the base of the track’s starting position.

“The goal of this test isn't just to move this sled,” he said. “It is to engineer an acceleration system that is scalable for passengers and freight and to bring the cost down,” said Hyperloop One co-founder Brogan BamBrogan.

One thing to note is that Hyperloop did not disclose the internal components of the system shown off on Wednesday. A full-scale test is expected to take place by the end of 2016.

In general terms, Hyperloop’s magnetic-based propulsion sounds very similar to MagLev, another magnetic levitation system already in existence. But in practice, the underlying principles are quite different. Maglev uses a hexagrid configuration and runs in open air, allowing for cheaper architecture at the expense of increased air resistance. By contrast, Hyperloop is exclusively bound between two points of destination and uses a huge partially-evacuated transportation tube. Incorporating multiple stops along the track will decompress the partial-vacuum, defeating the purpose of building a low-cost solution.

Also, MagLev reduces air resistance and noise by streamlining the pods and positioning them in a closely-spaced convoy so that the lead vehicle bears the brunt of the wind resistance. Conversely, a large suction fan is incorporated within the front of each Hyperloop pod positioned in the convoy. These fans suck in the air and use it to push against the inner walls of the transportation tube to levitate the pods and provide stability.

Check out EVWorld for a more in-depth comparison between Hyperloop and MagLev.

Source: Phys.org and EVWorld

Advertisement

Learn more about Electronic Products Magazine