By STEPHEN WHALLEY,

Chief Strategy Officer,

MEMS & Sensors Industry Group

www.memsindustrygroup.org

According to the United Nations, 9.6 billion people will live on planet Earth by 2050. Feeding these mouths will require simultaneously meeting three great needs: quantity, environmental, and cultural. The World Resources Institute (WRI) forecasts that we will have to close the gap of approximately 70% between the amount of food we have today and the amount needed by 2050. We will also need to reduce agriculture’s impact on climate, ecosystems, and water. Finally, we will need to ensure that agriculture supports inclusive economic and social development.

For IBM Researcher and Distinguished Engineer Ulisses Mello and a team of IBM Research − Brazil scientists, the answer to these daunting challenges lies in real-time data gathering and analysis. They are researching how “precision agriculture” techniques and technologies can maximize food production, minimize environmental impact, and reduce cost.

What is “precision agriculture?” Consider that, traditionally, agriculture is practiced by performing a particular task, such as planting or harvesting, against a predetermined schedule. But by collecting real-time data on weather, soil and air quality, crop maturity, and even equipment, labor costs, and availability, agriculturists can use predictive analytics to make smarter decisions. The latter, more technological process is what’s meant by “precision agriculture.”

With precision agriculture, control centers collect and process data in real time to help farmers make the best decisions with regard to planting, fertilizing, and harvesting crops. They place sensors throughout the fields to measure the temperature and humidity of the soil and the surrounding air. In addition, these control centers take pictures of fields using satellite imagery and robotic drones.

Until now, larger companies were better suited to precision agriculture technologies because these technologies require a robust IT infrastructure and resources to do the monitoring. However, Mello believes that cloud-enabled technologies will lower the entry barrier to allow smaller farms and co-ops to use mobile devices and crowdsourcing to optimize their own agriculture. “A farmer could take a picture of a crop with his phone and upload it to a database, where an expert could assess the maturity of the crop based on its coloring and other properties,” said Mello. “People could provide their own reading on temperature and humidity to substitute for sensor data, if none is available.”

The MEMS & Sensors Industry Group (MSIG) is keenly interested in the connection between sensors and their use in helping to address major world problems, such as hunger, environmental issues, and healthcare access. In fact, MSIG anticipates that by the year 2020, more than a trillion sensors (TSensors) will populate these wide-ranging applications. But using sensors to help feed billions of humans will require water and soil management, precision agriculture, and improvements in crop yields and quality.

IoT red and ripe

One agriculture-related Internet of Things project worth mentioning, “The Internet of Tomatoes,” is being driven by the smaller farming community. Members of MSIG conceived this project at the 2014 MEMS & Sensors Executive Congress, when keynote speaker Francis Gouillart, president and co-founder of the Experience Co-Creation Partnership, threw down a challenge to the audience. He called upon audience members to collect data along the tomato Ag-Food value chain through the use of sensor-based, IoT technologies. He exhorted these conference attendees to engage all of the tomato value chain’s stakeholders, or actors, in a data-driven dialogue aimed at transforming the overall quality of the finished tomato product. Through “co-creation,” he envisioned improving the efficiency of growing, distributing, processing, and retailing those tomatoes.

Fig. 1: At the heart of the Internet of Tomatoes Project is a sensor-based system to measure the quality of the popular red produce. Source: ADI.

Analog Devices (ADI) eagerly accepted the challenge and has been working with Gouillart and the entire farm-to-table supply chain ever since. ADI is developing the core technology through its Fenway development platform (Fig. 1 ), which includes several of the company’s proprietary sensors and a microcontroller. ADI is also leveraging multiple technical agreements or partnerships with other companies. In fact, ADI recently announced an agreement with Consumer Physics, which offers SCiO, a molecular sensing device being integrated into the “Internet of Tomatoes” approach. ADI also provides the rapid-prototyping team needed to constantly adapt the technology to the needs of tomato farmers and other value-chain players in various parts of the world.

The Internet of Tomatoes project provides a neutral, transparent, data-driven view of productivity and quality along the tomato chain that will lead the various actors to different, mutually beneficial choices, thereby leading to a transformation of the entire value chain and fostering the development and sales of the enabling technologies and associated services.

De-stressing plants

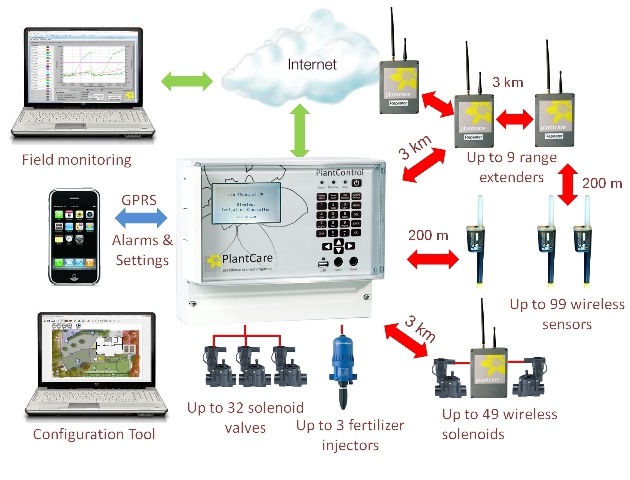

Another small company, the Swiss-based PlantCare AG, offers the “world’s first self-learning irrigation computer that intelligently evaluates the measurements from up to 60 wirelessly linked soil moisture sensors.” PlantCare AG’s system (Fig. 2 ) uses sensors to ensure that plants grow in a stress-free way: they receive enough water, but not too much, which also makes them less disease-prone and more pest-resistant. With drought conditions being a pervasive threat in numerous global regions, conserving water provides a more sustainable approach to irrigation.

Fig. 2: PlantCare AG’s system aims to control the growth environment — moisture, chemistry/fertilizer, and other factors — so that produce undergoes less environmental stress from seeding to harvest. Source: PlantCare AG.

If water, sun, and nutritious pest-free soil are the basic fundamental building blocks of farming, then let’s not forget the bees. Pollinators are necessary for one-third of all crops that are used directly for food worldwide. But the last decade has been hard on them, reducing their numbers year after year. Bee colony collapse disorder (CCD) contributed to a loss of 42% of the bee population in 2015.

Apiologists — honeybee researchers — attribute CCD to multiple sources, including parasites, viruses, and pesticides. The primary parasitic suspects are mites, which infect and destroy honeybee colonies. Eltopia Communications’ Intelligent Foundation platform, code-named MiteNot, uses multiple sensors, an MCU, and power management components from STMicroelectronics to monitor and collect data on environmental conditions and to eliminate parasites that contribute to honeybee CCD. The platform is a compostable film that senses the lifecycle of the bees and parasites. The solution then interacts with the colony to apply targeted heat to sterilize the mites without harming the bees and without pesticides. A quick search on the internet reveals other projects that sense beehive conditions and projects in which sensors are fitted on the backs of bees.

Herd maternity

On the cattle front, various sensors are being deployed to monitor animal health, optimum mating times, pregnancy detection, and birthing times. One such device, Moocall (Fig. 3 ), is a non-invasive, tail-mounted sensor that gathers over 600 pieces of data per second. It can accurately predict when a cow is most likely to give birth by measuring tail movement patterns triggered by labor contractions. When these tail movements reach a certain level of intensity over time, Moocall then sends an SMS text alert directly to a cell phone, on average one hour prior to calving.

Fig. 3: Designed to be mounted on a cow’s tail, the Moocall sensor gathers and transmits data about tail movements, which indicates when a cow is going into labor. This data is used to signal a farmer at such a time when he or she needs to become actively involved. Source: Moocall.

All of the preceding examples illustrate how technologists are, thankfully, addressing the task of solving world hunger and quality food for all, from the top to the bottom of the food chain. Even so, everyone must work toward common-sense ways of individually living our lives in harmony with Earth’s ecosystem. Besides our own sense of what’s right and needed, in the future we might also be able to call upon the use of billions, and maybe trillions, of sensors (see MSIG’s TSensors Initiative) to tell us what is going on in the soil, water, air, crops, and livestock. With the help of precision farming, we can be a lot smarter about ensuring that there’s food on the table in 2050.

Advertisement

Learn more about MEMS Industry Group