By SAMY AHMED, Manager Applications Engineer and DR. DIRCK SOWADA, Senior Manager, Test & Characterization, Product Marketing, Sensors,

Vishay Semiconductor GmbH

www.vishay.com

While the brightness and color effect must be specified and implemented at the time of installation of conventional light sources, the arrival of white LEDs for indoor use presents the user with a variety of changeable and creative possibilities. Using binning and suitable photometry, complex light scenarios can be chosen and precisely controlled. Even the aging process of the LED light sources can be taken into consideration.

Even though white LEDs have a variety of options and advantages over conventional light sources, they require additional effort and expense to ensure that the desired lighting conditions remain variable and predictable as well as stable over the long term. An active control system can help here. Besides long-term changes, such as the loss of brightness of an LED over its lifetime and the aging process of the converter mass in white LEDs with the resulting drift of the color temperature near the black-body curve, it is desirable for the control system to react to, and to compensate for, high-speed events. Those include the change of optical parameters over temperature, the failure of individual LEDs in the LED cluster, and changes to the operating point (brightness EV , color temperature CCT) by the end user. Such a control system can now be realized with just one optical sensor.

Light sensors

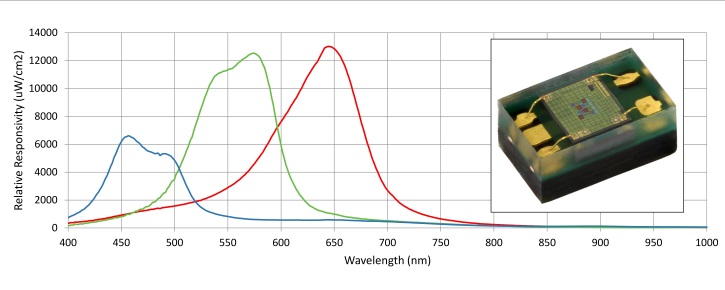

To implement a white-light control scheme, there are several sensor options. Simple ambient light sensors, such as the TEMD5510FX01 or TEMT6200X01, can be used to control brightness by measuring the analog photoelectric current corresponding to the responsivity of the human eye. Another alternative is RGB sensors, such as the VEML6040, which is based on the CIE1931/DIN5033 standard. The VEML6040 is a CMOS chip containing an amplifier, analog and digital circuitry, and four photodiodes with bandpass filters for the red, green, blue, and white spectral components. The RGBW information can be retrieved by a microprocessor via the I2 C bus. In this way, a control loop can be implemented simply for brightness and color temperature for mixed scenarios of warm-white/cool-white LEDs. Even controlling pure color RGB light sources or heterogeneous assemblies made of RGB and white LEDs is conceivable. Precise control systems that are stable over temperature are possible (Fig. 1 ) due to the implementation of color filters for the sensor in the patented Filtron technology with a good approximation of the filter characteristics to the standardized responsivity curves of CIE1931. Vishay Semiconductors uses this technology in the VEML6040 as well as the VEML6075 digital UVA/B sensor and VCNL4040 proximity and ambient light sensors to achieve the necessary spectral responsivity.

Fig. 1: Relative spectral responsivities of the RGB channels in the VEML6040 RGB sensor, based on the responsivity of the human eye per CIE1931.

When it comes to temperature in the control loop, two different temperature mechanisms need to be taken into consideration. One is the effect of ambient temperature changes (typically from 20°C to 85°C) on the spectral characteristic of white LEDs. The other is the intrinsic heating of the LED during operation, which also affects the color temperature in ways that depend on the brightness (current) and the LED technology.

Active control of light parameters

The control systems of today often make use of families of characteristic curves for brightness and color temperature that have been measured in advance. These curves are determined under optimal thermal conditions, and a favorite solution is to make them available to the control system via an EEPROM. While such solution approaches are very fast when changing brightness or color temperature, they are very inflexible because of the lack of actively monitored optical quantities. Expanding the control system by also measuring the temperature near the LED heat sink can ideally eliminate the thermal drift of the digitized family of curves. However, taking the aging of the lamp into consideration is virtually impossible.

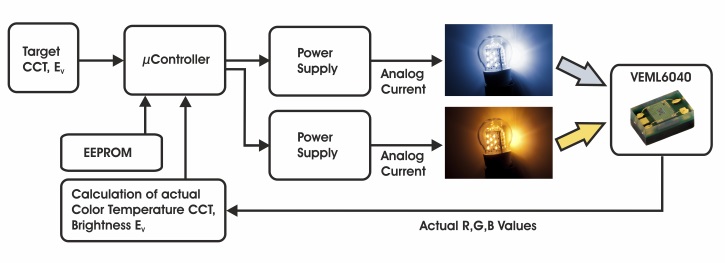

Fig. 2 demonstrates the use of the VEML6040 RGB sensor in an active feedback control system for mixed lighting using warm-white and cool-white LED clusters based on a microcontroller and constant current power supplies with an analog control input (0–10 V) or a digital control input (Dali, DMX). The brightness EV and color temperature CCT are calculated from the measured RGB sensor values using mapping matrices that are determined once for the lighting system and that must be stored in an EEPROM. The creation of such a mapping matrix is described in the VEML6040 application note . The optional storage of a family of curves (CCT, EV as a function of the LED currents) is useful to set the initial operating point quickly when the user switches the brightness and color temperature. From this, the control loop moves to the final operating point according to the target values. With the integration time of the sensor set to a default of 80 ms for one set of RGB values, an attack time of less than 400 ms to 600 ms is possible.

Fig. 2: Active control system for brightness EV and color temperature CCT using a microcontroller and RGB sensor.

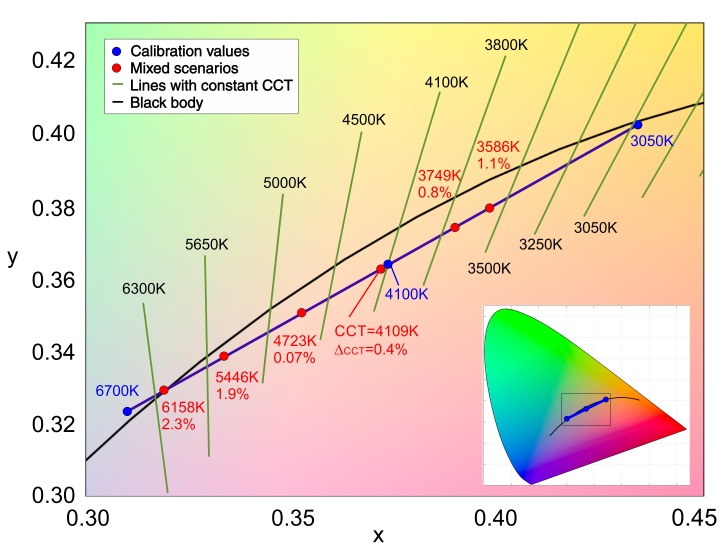

To verify the control circuit and the performance of the RGB sensor, a lighting system was set up using two LED clusters (12 W, Ra > 90, max. 350 mA) in warm white (CCT = 3050 K) and cool white (CCT = 6700 K). In addition to the RGB sensor, the optical parameters were measured and checked using professional photometry and a spectral photometer.

In a first step, the RGB values of the sensor were determined for the light scenarios of 100% warm white, 100% cool white, and 50% warm white/50% cool white. In addition, the tri-stimulus XYZ values were measured using a spectral photometer, and they were used to define the transfer matrix R,G,B -> X,Y,Z. With the help of this matrix, the actual optical quantities of brightness and color temperature were computed in the control system. The new currents for the warm-white and cool-white LED clusters were then calculated and passed to the power supplies. This closes the control loop.

After determining the matrix, any number of mixed scenarios using warm white and cool white may be calculated and controlled. As a measure of the quality of the control action, the error between the target value and the actual value of the color temperature and brightness was analyzed. To visualize the measured color temperatures, the relevant excerpt of the x/y color space from CIE1931 for the mixed area of the LED configuration is reproduced in Fig. 3 . In addition to the three calibrated values, a few mixed scenarios were entered. The color temperature of these scenarios was determined using the RGB sensor. The error entered in each case describes the difference between the RGB sensor and a professional measurement reference.

Fig. 3: Control area for the color temperature CCT in the x/y color space as per CIE1931.

The accuracy of the entire control system is decisively affected by the accuracy of the RGB sensor and the control algorithm. While repeatable accuracies for the CCT and EV over the entire parameter space (LED current: 0–350 mA) of better than 0.5% deviation are achieved using a simple algorithm to calculate the LED currents, a measurement inaccuracy of CTT V can be achieved. These slight differences are acceptable for indoor light control.

The measurements show that an active control system of the two most important optical parameters for indoor use can be implemented simply with an RGB sensor to create conditions that are stable over the long term and that react precisely to a quick change.

Summary

An active control system based on the VEML6040 RGB sensor can significantly increase user convenience and the light quality of modern indoor lighting scenarios based on white LEDs. The goal is to provide the customer with a standalone system that does not require the end user to know anything about the control system or the optical parameters. After selecting a light scenario based on the user-friendly settings of brightness and the lighting effect in the form of the color temperature (warm, neutral, cold), an active control system itself can take into account and compensate, to the greatest extent possible, for disturbance variables such as the aging of the light source and the effect of temperature. From the current point of view, this adds value to indoor comfort and convenience.

Advertisement

Learn more about Vishay Semiconductors