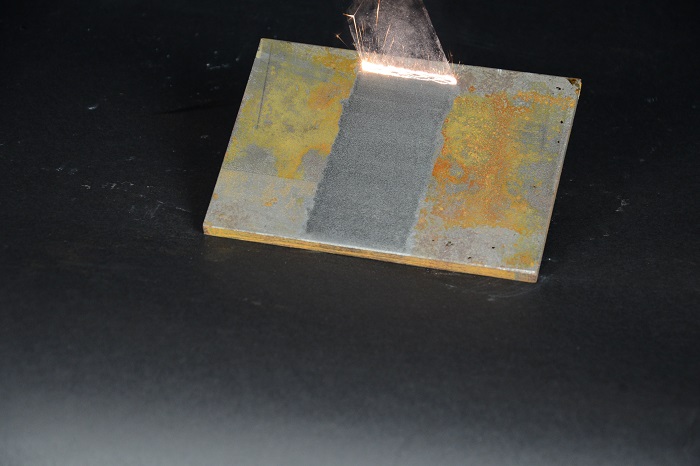

The cleaning laser demonstrated above comes from the folks at P-laser.com. It’s a fairly new technology, but one that is gaining tremendous interest due to all of the many benefits it has over traditional cleaning methods like chemical, thermochemical, grinding, blasting, and others.

The laser is short pulsed — basically, it fires bullets of light at a clip of approximately 200,000 pulses per second. The result, as you can see in the video above, is instantaneous.

In terms of how it works, one must first understand that when an object has a layer of rust, paint, grime, or what have you atop it, this means there are two layers that need to be dealt with in order for the object to truly be cleaned. The top layer is the contaminated area — the laser is tasked with cutting through this layer in order to reach the layer below it, which is the base material. The latter layer will serve to reflect the laser energy, while the former layer will absorb it. The result is the annihilation of the contaminated area.

Now, it should be noted that depending on what, exactly, makes up the top layer, there are two things that happen when the bullet of light hits it: (1) The crimp effect: the base material will stay cold while the absorbing layer heats up. This results in the contaminant crimping off the base material. (2) Evaporation, wherein the contaminant heats up to the point that plasma is created around the working area. This results in everything around it evaporating.

Besides efficiency, there are a couple of other benefits to laser cleaning, including no chemical waste, low noise, no dust, low-running costs, and no other medium necessary beyond electricity.

P-laser has a roster of laser cleaners available, ranging from low power (10W-100W) to mid-to-high power (200W-1000W). All are equipped with a 1D or 2D scanner (for manual use or robotic integration), cleaning software, marking software, and industrial-level components that are expected to give the cleaners an expected lifetime of approximately 50,000 hours.

To learn more, visit p-laser.com

Advertisement

Learn more about Electronic Products Magazine