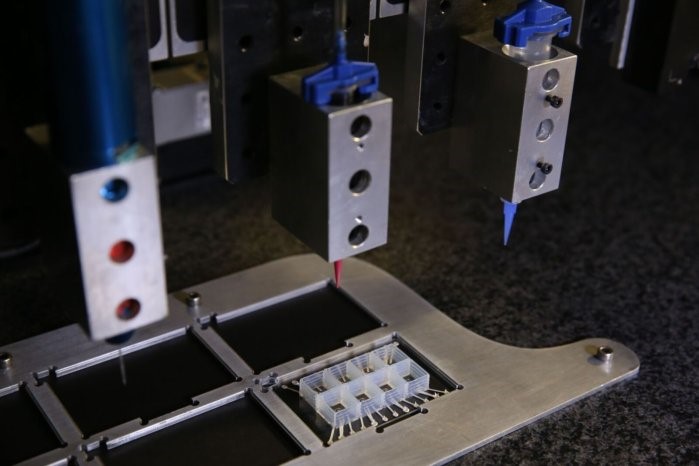

Scientists are avoiding the testing of animals by using microphysiological systems — or organs-on-chips — to analyze how drugs, cosmetics, and diseases may affect the human body. Harvard researchers have helped to rectify the chips’ costly manufacturing expenses by developing materials allowing 3D printouts of the devices.

Organs-on-chips are about the same size of a USB stick, incorporating living human cells to emulate organs’ functions and certain diseases. Imitating the lungs and intestines, among other organs, the chips require collaboration with microscopes and high-speed cameras to work efficiently. Travis Busbee, a co-author of the research, said the team approached these challenges with the goal of improving the chips’ digital manufacturing. “By developing new printable inks for multi-material 3D printing, we were able to automate the fabrication process while increasing the complexity of the devices,” he shared.

Researchers ended up creating six 3D-printable materials that replicate human heart tissue and include soft-strain sensors, which allow for studying tissue over time. Key areas of interest related to the tissue are how their contractile stress varies and how exposure to toxins impact organs.

“Researchers are often left working in the dark when it comes to gradual changes that occur during cardiac tissue development and maturation because there has been a lack of easy, non-invasive ways to measure the tissue’s functional performance,” said John Ulrik Lind, first author of the paper. “These integrated sensors allow researchers to continuously collect data while tissues mature and improve their contractility.”

Experimentation with the chips has proven that the manufacturing process can easily be repeated and adapted to create other organs. While one of the key benefits is obviously finding alternatives to animal testing, which often isn’t even accurate because of animals’ different pathophysiology, the study also opens up an entirely new form of 3D printer use. It also has the potential of simplifying disease research, which can normally take up to several years; according to the Wyss Institute, testing a single drug compound can cost more than $2 billion.

The research team even released a video displaying the chips and their potential. Check it out below!

Source: Computer World, New Atlas, Futurism

Advertisement

Learn more about Electronic Products Magazine