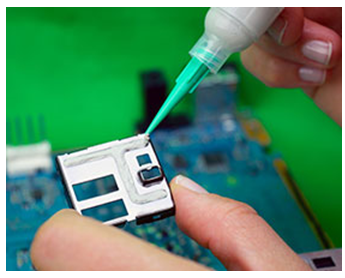

Master Bond MasterSil 973S-LO is a two component, silver filled silicone with superb electrical and thermal conductivity. Most importantly, it passes NASA low outgassing testing requirements. It is an addition cured system and does not require air for curing. Unlike many other types of silicones, it can cure in wide cross sections as well as in depth(>1 inch). The mix ratio is 100 to 5 by weight and after mixing it has a paste viscosity. The curing schedule is 25-45 minutes at 250-300°F or 1-2 hours at 160-200°F.

After curing, MasterSil 973S-LO is an outstanding electrical conductor (see table below). Its exceptionally low volume resistivity allows it to be used for many different applications involving bonding, sealing and coating. It bonds well to a wide variety of substrates, including metals, ceramics, glass, composites as well as many types of rubber and plastics. The system has very good flexibility and elongation. It can withstand aggressive thermal cycling as well as thermal and mechanical shock. As mentioned previously, it is a paste like system with minimal flow. Its consistency also allows it to be utilized as a form-in-place conductive gasketing material. The system is 100% solids and its color is silver. The service temperature range is -120°F to +400°F. In summary MasterSil 973S-LO serves up an amazing array of product properties. Most conspicuous are its low outgassing properties, stellar electrical conductivity and being a silicone, great flexibility and temperature resistance. It is used in aerospace, electronic, optoelectronic and specialty OEM applications where this combination of properties is needed and desirable.

Advertisement

Learn more about Master Bond