For the makers who need to construct their own capacitors, you must choose a dielectric for it, otherwise known as the material that goes between the plates. One popular material is paraffin wax that is typically used for making candles. Another is resin, an easy to find material often used for automotive body repairs.

The issue that often arises is that you may need to do the calculations for the capacitor dimensions ahead of time, rather than just putting something together. This means you’ll need to know the dielectric constant of the material. The manufacturers of the paraffin wax or the resin won’t know that figure, so it’s up to you to measure the dielectric constant yourself.

The dielectric constant is a measure of how much capacitance has increased when you insert an insulating material between the plates of the capacitor. It is the ratio of the capacitor’s capacitance with the material. It varies according to temperature, decreasing with a rise in heat. Usually, the variance is small.

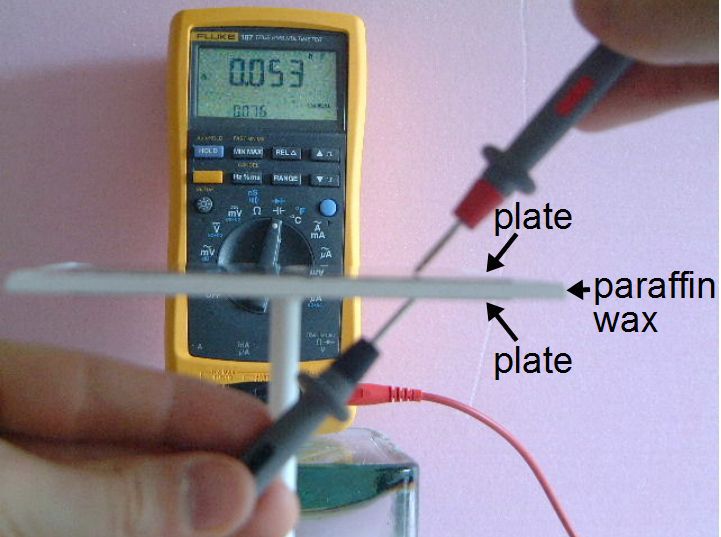

If you know the dielectric constant is the ratio of the capacitor’s capacitance with the material to its capacitance, you have a way to measure it. To get that number, measure the capacitor’s capacitance with the material in place, and then measure its capacitance again but without the material. Divide the first value by the second value and you have the material’s dielectric constant.

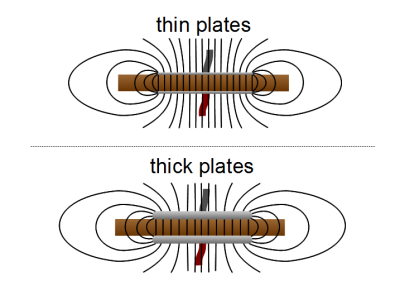

Two factors to consider when measuring are resistivity and the effect of the edges. If you have a flat plate capacitor, then the electric field is different at the edges than between the plates. It’s different depending on the geometry of the plates. Thin plates have sharper edges and will have denser electric field lines at the edges. One way to minimize the effect of the edges is to have a large plate area compared to the amount of edge, making it less significant.

The other factor to consider is the resistivity of the dielectric material. Naturally, you’ll want your capacitor to have a strong insulator as the dielectric, but since the device is homemade, it’s possible the dielectric material has some conductivity. After you’ve constructed your material, place plates on either side and measure the resistance from plate-to-plate using the resistance scale of your meter. It should display what your meter typically shows for something that has too high of resistance to measure.

Do you have any other tips for measuring dielectric constant for a capacitor?

Source: Hackaday

Advertisement

Learn more about Electronic Products Magazine