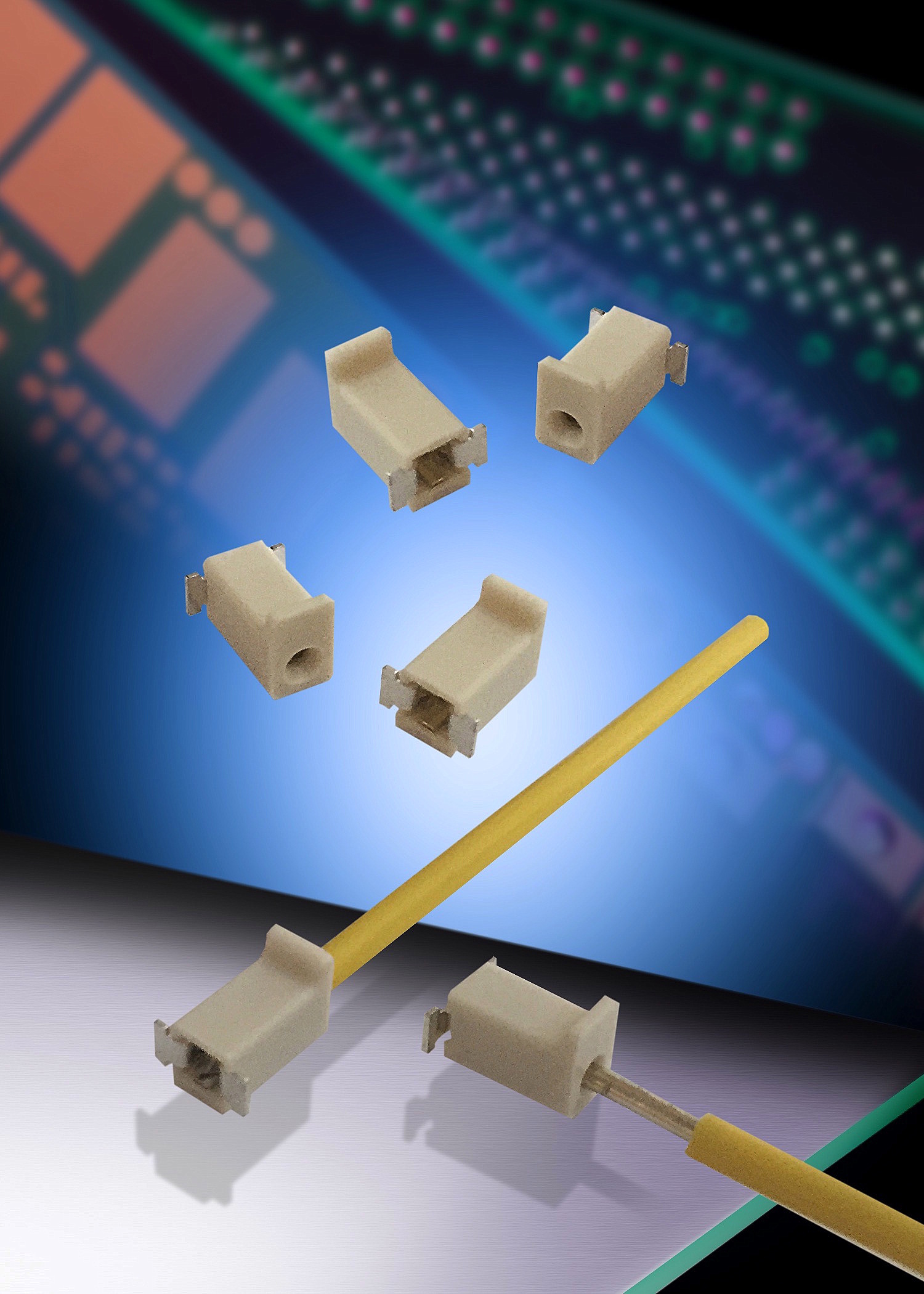

Here is a compact and cost-effective alternative to hand-soldering in high-volume 18-AWG wire applications. AVX has released a vertical connector that bridges the gap between inexpensive but highly inconsistent hand-soldering processes and expensive two-piece connector systems.

The 18-AWG applications in power supplies, LED drivers, and industrial and motor controls have perpendicular terminations and limited board space. So the new 58-9296 Series connectors feature a unique, stamped, and formed phosphor bronze box contact that maximizes both board attachment and wire-capturing strength.

Thevertical poke-home connectors are 23% smaller than the existing vertical connector solutions. So the 58-9296 Series single-position connectors can fit into extremely tight spaces between larger and densely populated plated-through-hole (PTH) components.

The 58-9296 Series vertical connectors also boast tight tolerances in critical areas to minimize the potential for ingress resulting from the secondary potting or epoxy encapsulation processes. Such processes are usually employed to protect industrial electronics from water and other harsh environmental hazards.

The 58-9296 Series poke-home connectors are able to operate in temperatures spanning –40°C to 130°C. And they can withstand mechanical and environmental stresses associated with 18-AWG wires in industrial applications such as machine controls, fire sensors, and smart grid meters.

Next, the poke-home connectors feature lead-free tin plating that enhances corrosion resistance and contact strength. And the dual solder tabs effectively anchor the connector onto PCBs. Furthermore, instead of costly Kapton tape, the vertical connector offers an integrally molded flange with a vacuum pick-up point for automated SMT placement.

Advertisement

Learn more about AVX