GARY MACDONALD,

Automotive Strategic Marketing Manager,

Dialog Semiconductor,

www.dialog-semiconductor.com

Whether it’s navigating to a friend’s new house, listening to our favorite music or talking hands-free, our vehicles and the technology we use to make our lives easier are becoming more intertwined. In addition to entertainment and convenience, we also rely on the vehicles technology to monitor and warn us of anything requiring attention, assist us to park, and automatically open the trunk when our hands are full with groceries. Many of us take these features for granted, but underlying them is a highly complex combination of electronics, software and computing power. This increased sophistication and integration of technologies within our vehicles requires correspondingly advanced and efficient power management solutions.

The automotive industry has always been at the forefront of innovative transportation solutions, but modern carmakers are embracing technologies that go well beyond simply improving ride quality or fuel emissions. In recognizing how connectivity is changing the consumer-facing products and services in nearly every industry vertical, automakers are reaching across sectors and vendors to help integrate a wealth of connected devices into new cars to realize improvements in communications, entertainment, driver assistance and safety.

While many of these features are familiar to drivers today – such as infotainment systems and GPS navigation consoles, just to name a few – even existing technology is going to be superseded by some of the automotive innovation soon to hit the streets. Although self-driving cars may still be a few years away, there will be a greater degree of intelligence and even autonomy within each vehicle in the near term that will be able to help make important decisions for drivers.

Many vehicles are already capable of improving safety by braking for drivers, or even assisting with control of the steering wheel during lane departure scenarios. However as cars move to become fully-autonomous, the energy required to power these functions has already become a significant challenge for vehicle manufacturers and their suppliers.

What’s helping fuel this new relationship between car and driver are significant advances in processing power offered by highly integrated microprocessors and SoCs that are optimized for automotive use. These extremely complex ICs are designed to bridge communication between the various different devices within the vehicle, as well as with other cars sharing the road, and comprise increasing numbers of power hungry processing cores.

Highly-agile PMICs enable “always-on” technology

Powering these very complex systems requires next-generation power management ICs (PMICs) and converters that are designed to meet the high quality and reliability demands that a consortium of SoCs need to function. Take, for instance, the DA9210-A, which is a 12 A dc/dc buck converter that builds upon the high standards used in the high-volume smartphone market.

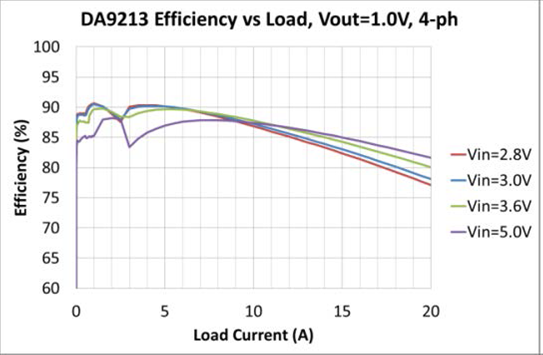

Fig. 1: The efficiency vs load graph of support 12 A load currents in single output and 24 A in parallel output configurations.

Primarily designed to supply the high currents required by the SoCs multiple processing cores, these sub-PMICs seamlessly communicate with a system-PMIC in a master-slave configuration to power tech with escalating energy demands. By supporting load currents of up to 12 A in a single-output configuration and 24 A in a parallel output configuration, such chips meet the high-efficiency standards that the latest generation of automotive technology requires.

PMICs like these are ideal for automotive use because they can be reconfigured using software to accommodate a growing number of integrated technologies within the cockpit, and also outside of the vehicle. Semi-autonomous features like those described above, for instance, rely on cameras placed around the exterior of the vehicle that communicate with each other – and even combine perspectives – to inform both the driver and the applications making decisions for them.

These external cameras live inconspicuously on the exterior of the car, facing a lot more exposure to potential damage than technology within the cockpit, including extremes of temperature, moisture and direct sunlight. The SoCs used to process the images produced by these cameras therefore benefit from scalable, flexible, multiple-rail PMICs that can be expanded upon to supply adequate power to each at an economy of space. This makes the proximity between processors and the technology they operate less of an issue, especially when it comes to heat dissipation within close confines.

These same characteristics come into play when keeping infotainment consoles both operational and compact. Like the camera modules behind each infotainment unit LCD screen, space and height is limited, and manufacturers need PMICs that allow for heat dissipation via air convection to prevent the need for fan-cooling. If a manufacturer has higher profile parts, air doesn’t move around them as smoothly, which is necessary for these modules to operate without components overheating. For chips like the DA9210-A, the switching operation takes place at a high-frequency, which enables the power systems to use smaller, lower-profile components, and therefore better dissipate any byproduct heat.

PMICs like this have a proven track record of reliability in the consumer space, and therefore qualification to automotive standards and integration into next-generation vehicles can take place with relative ease. This presents far fewer limitations for vehicle manufacturers to make their cars “smarter.” As the convergence of mobile technology and cars increases, advanced output configurations can help support more features, making our vehicles useful tools for far more than just commuting.

Originally published on Power Electronics News

Advertisement

Learn more about Dialog Semiconductor