By Brian Santo, contributing writer

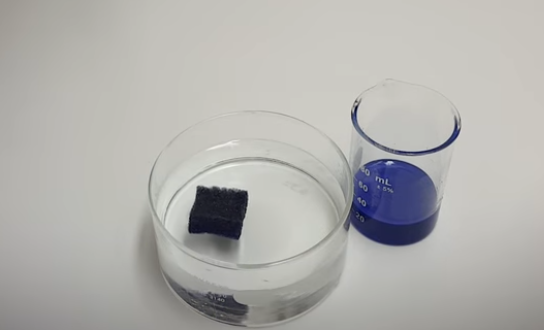

There’s another oil spill? Can’t you just use a big sponge to clean it up? That might be possible. Researchers at Argonne National Labs have devised a sponge with properties that should make it especially effective at cleaning up oil spills.

Based on a standard polyurethane foam covered with an oil-attracting substance, using the Oleo Sponge is simple. The processes involved in making it are about as high-tech as you can get.

The Oleo Sponge has two engineered coatings. The first coat is a metal oxide primer applied using a technique called sequential infiltration synthesis (SIS). SIS is a form of atomic layer deposition (ALD) in which a polymeric material (e.g., polyurethane) is infused with inorganic material. SIS has been investigated as a way to improve the lithographic process in semiconductor manufacturing as IC structures get shrunk smaller and smaller.

In the case of the Oleo Sponge, the inorganic material is a metal oxide. The metal oxide is a substrate for an oleophilic (oil-loving) substance. The Argonne National Laboratory (ANL), where the sponge was created, identified neither the specific metal oxide nor the oil-soaking substance it devised.

The Oleo Sponge's coating enables it to absorb up to 90 times its weight in oil. More importantly, the Oleo Sponge is unique in its ability to suck up oil suspended under water, according to the ANL. Existing oil clean-up methods can gather oil floating on the surface of water, but in most spills, subsurface oil is almost as voluminous as the surface slick.

The Oleo Sponge. Image Source: anl.gov.

Used sponges can be simply wrung out and reused. Single sponges have been wrung out hundreds of times with no sign of breakdown, according to ANL.

Furthermore, the wrung-out oil is recoverable. In contrast, ANL said on its website, “Current sorbent technologies soak up oil in a single use, and the oil-saturated materials must then be disposed of.”

The Oleo Sponge appears on its way to being commercialized. Hemant Bhimnathwala, who manages ANL’s Business Development Group, told the Voice of America that more than 100 companies have queried the lab about partnering on the technology.

Overall, the lab said that there is nothing about the sponge or the materials applied that is environmentally harmful.

Advertisement

Learn more about Electronic Products Magazine