By Majeed Ahmad, contributing editor

A relentless increase in data rates is turning the PCB connector landscape upside down. And the clean transmission of signals via PCB traces is becoming more critical while data speeds in servers, switches, routers, and storage devices hit the roof.

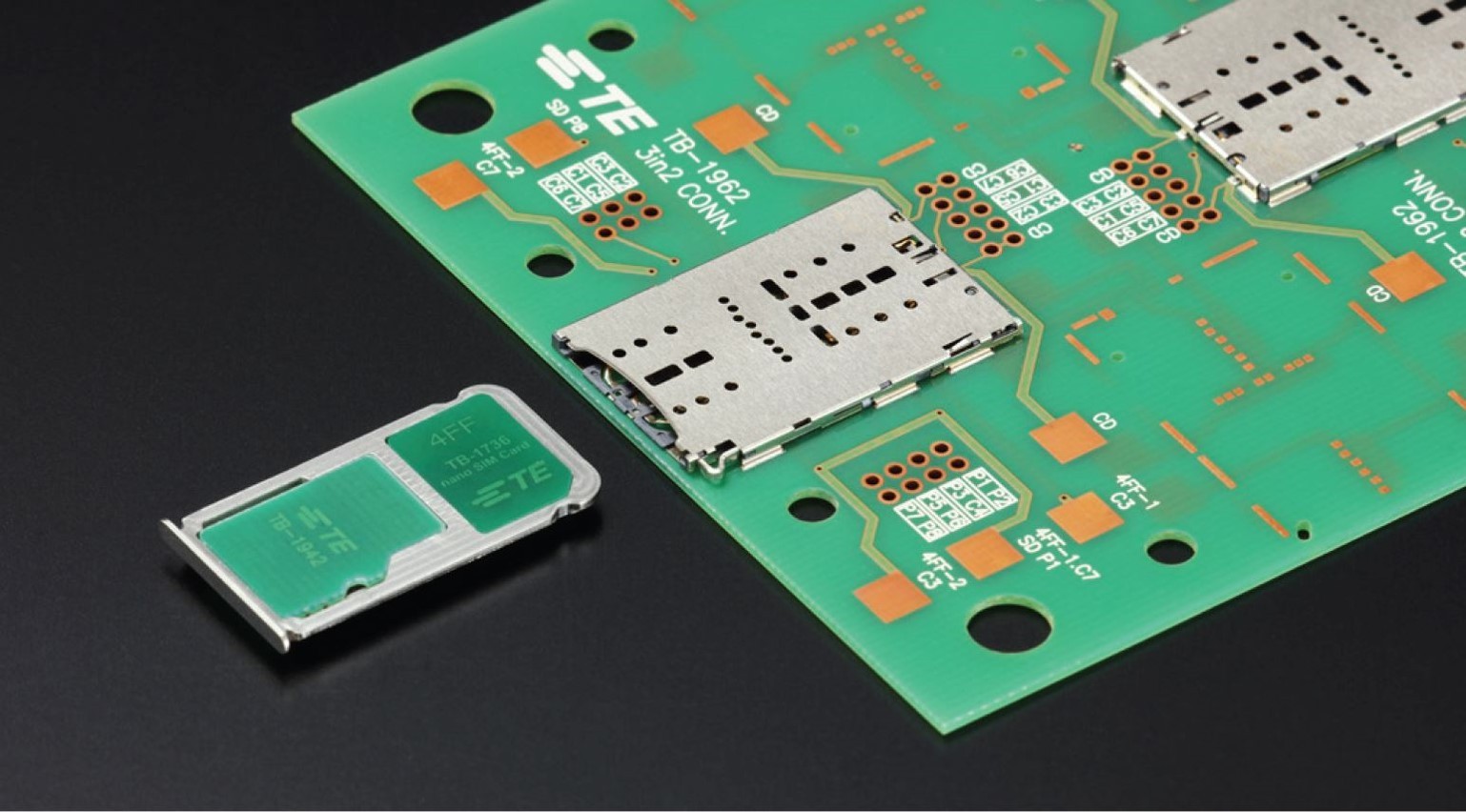

Image: TE Connectivity.

So how do we enhance I/O connections on the board? Here are a few connector-related design parameters that matter a lot in the creation of efficient PCB designs:

Form factor

First and foremost, a small connector footprint simplifies the PCB design, lowers the cost, and reduces the transmission losses while making the connection from point A to point B. Here, a small contact pitch makes the connector slimmer and, thus, facilitates smaller boards and backplanes.

For instance, connector receptacles can be mounted in parallel with a smaller pitch distance, and subsequently, the small receptacle footprint facilitates the connector size reduction. The smaller width of the receptacle is especially useful when multiple connectors are positioned on a single PCB side by side.

Signal losses

The insertion losses are becoming critical with an exponential rise in data rates. So how to overcome the insertion losses? The internal structure, as well as contacts inside the connector, play an important role in improving signal integrity and minimizing insertion losses.

The connector can also enhance the signal interface by improving the airflow and channel impedance.

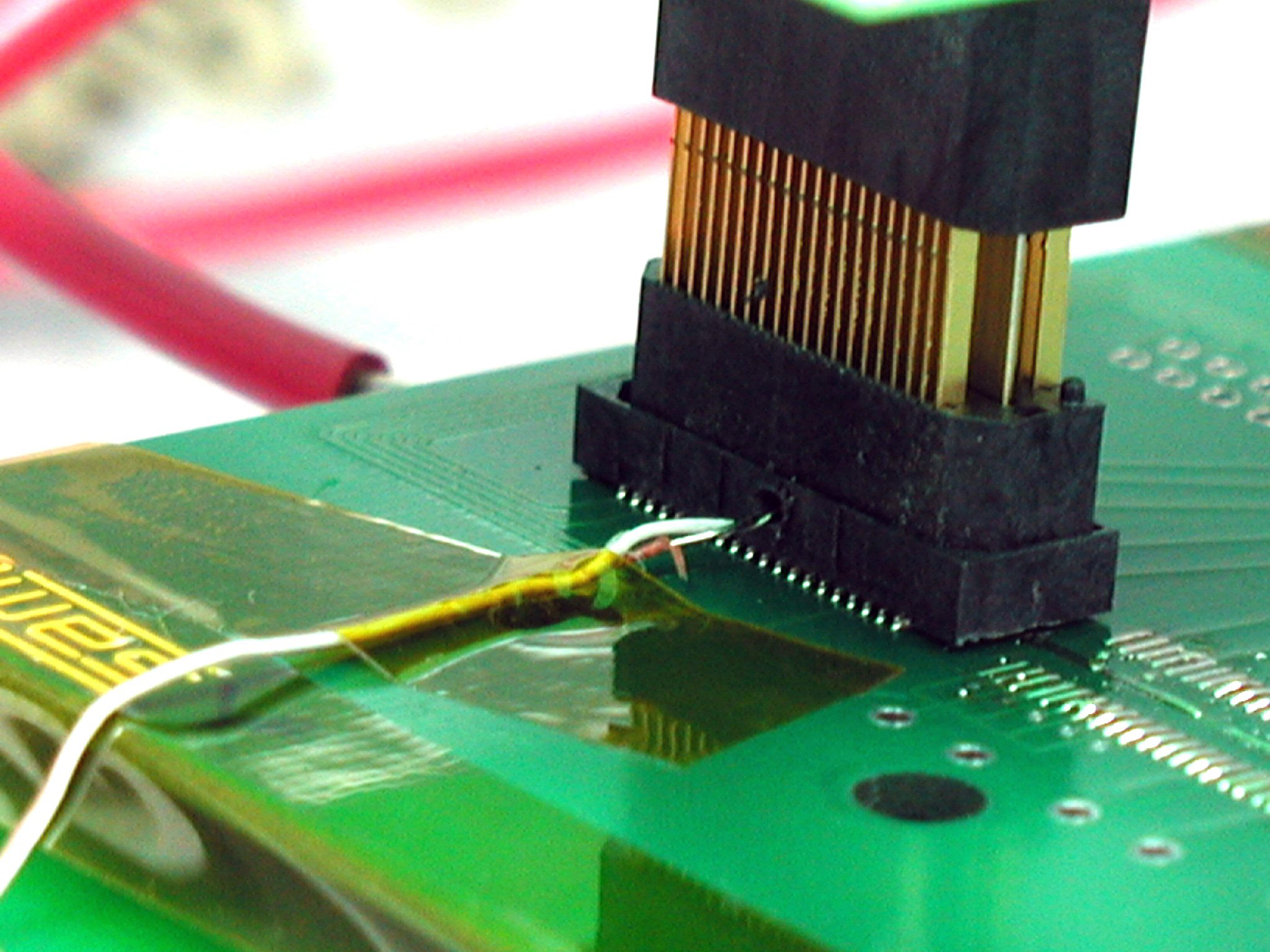

Image: Samtec.

EMI and ESD shielding

The shield against electromagnetic interference (EMI) and electrostatic discharge (ESD) is becoming more crucial at higher data rates. Here, physical envelopes, as well as special mounting and termination mechanisms, play a significant role in ensuring protection against the EMI and ESD effects.

Cable termination

It’s the transitioning point at which the cable is terminated with the connector, and it’s instrumental in overcoming signal losses. For example, some PCB connectors come with pre-loaded springs to prevent unintended cable removal.

And then there are connectors that integrate the wire-termination unit and cable clamp into a single plug shell.

Mechanical strength

A flexible, robust, and durable connector design means that it can withstand cable pull, heat, shock, vibration, and other external forces. The PCB connector’s mechanical strength also ensures proper mating and connection security.

The connector manufacturers facilitate this vital requirement with signal contacts that are pre-loaded, positioned, and protected in individual slots to ensure appropriate connector alignment and mating. The connector suppliers are also using active latches, weld tabs, and board locks to ensure complete and secure mating.

Advertisement

Learn more about Electronic Products Magazine