By Spencer Chin, contributing editor

Driven by OEM needs to achieve higher connection density and performance, connector manufacturers are redesigning their products with new features and physical configurations. These design enhancements are vital as signal speeds and operating frequencies increase with the growth of supercomputers and high-speed networks. As applications such as streaming HD video, cloud computing, and connectivity of numerous devices in the Internet of Things become more prevalent, connector performance is keeping pace.

One example is the MULTI-BEAM card edge connectors from Pennsylvania-based TE Connectivity, a new line of power card edge connectors that support greater flexibility in configuration and printed circuit board (PCB) design. The connectors have a 1.00-mm signal contact pitch that provides up to 60% space savings and a 7.26-mm power contact pitch that provides up to 30% space savings over current products. The connectors provide higher power per contact up to 43 A.

Fig. 1: TE Connectivity MULTI-BEAM.

The connectors support PCB thicknesses of 1.57 mm and 2.36 mm and provide easier mating alignment with 1.3-mm-larger pads. The connectors enhance scalability and modularity with common power and signal contact modules; different contact quantities and positions; and AC/DC, low-power, and high-power options. Vertical, straddle, and right-angle mounting versions are available.

Backplane connector systems are also evolving to higher-speed performance. Molex (Lisle, Illinois) unveiled its Impact Zx2 Backplane Connector System, which supports data rates up to 28 Gbps in a modular design. The system utilizes patented ground shielding and footprint technology to enhance signal integrity performance.

Fig. 2: Molex Impact Zx2 Backplane Connector System.

The connector system employs a common-ground structure to improve crosstalk isolation, resulting in near-end crosstalk margin. Reduced-size compliant pins on both the backplane and daughter card modules optimize the PCB footprint to further improve signal integrity.

With space inside electronic equipment continuing to be at a premium, connector suppliers are redesigning connectors to handle greater power in the same or smaller footprint. Panasonic recently commercialized its 0.4-mm-pitch high-power board-to-board connector, which uses proprietary material processing technology to allow current ratings of up to 1 A per terminal, higher than the 0.3 A common in these connectors.

According to Panasonic, the connector allows a reduction in the number of terminals required and gives the designer more flexibility in designing terminals, including integrating power and signal terminals into a single connector.

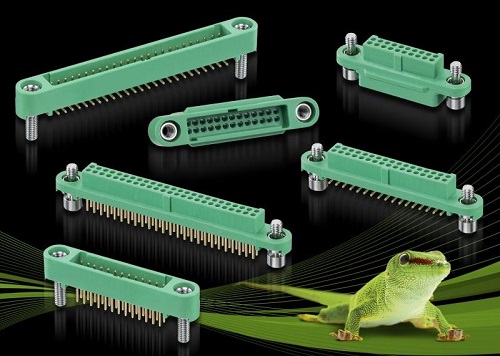

Smaller size is the claim to fame for Harwin’s recently expanded line of Gecko Screw-Lok (Gecko-SL) 1.25-mm-pitch connectors, which now encompass versions with 20, 26, 34, and 50 contacts. According to England-based Harwin, the Gecko-SL connectors are up to 45% smaller and 75% lighter than Micro-D-type connectors. These sizes are available in various configurations including vertical PCB throughboard and SMT in both male and female, horizontal PCB throughboard in male, cable housings in both male and female, and metal (aluminium) backshells for both male and female cable housings.

Fig. 3: Harwin Gecko-SL connectors.

The connectors carry up to 2.8 A individually and 2.0 A for all contacts simultaneously. They withstand operating temperatures from –65°C to 150°C and withstand 20g vibration and Z-axis 100g 6-m/s shock.

Automating assembly

With OEMs under constant pressure to reduce assembly costs, they are, in turn, requiring connectors that lend themselves to automated placement and soldering rather than requiring an additional manual assembly step. For instance, the 53-8702 Series connector from AVX Corporation (Fountain Inn, South Carolina) combines two contact technologies — insulation displacement and press-fit — in a single package. According to the company, incorporating the dual-assembly technologies allow for either pre-installation on a PCB to allow wire insertion during final assembly or pre-installation on a wiring harness. The connector is simply pressed into the PCB upon final assembly.

AVX’s connector enables designers to connect two PCBs that are not in the same orientation or alignment location more reliably than the flat flexible cable or flat printed circuit cables typically used to jumper between two zero-insertion-force connectors.

Compatibility with automated soldering processes is also becoming important as OEMs want to run the entire board assembly through soldering in a single pass. TE Connectivity introduced reflow-capable universal MATE-N-LOK connectors and Economy Power (EP) headers, both rectangular wire-to-board power connectors with thermoplastic housings that are designed to withstand high temperatures associated with reflow soldering.

The MATE-N-LOK headers have polarization features and a low contact mating force allowing for easy connections. They are designed for circuits rated 12 A/600 Vac and can withstand temperatures between –40°C and 105°C. The connectors are available with two to six positions in a single row and three to five positions in three rows.

The EP headers are designed as a shrouded header eliminating mis-mating due to alignment of the receptacle and header and provide positive audible latching to further ensure reliable assembly. The standard 0.156-in. (3.96-mm) centerline allows for mating with TE’s existing EP II wire-to-board connectors. The headers are designed for circuits rated 12 A/600 Vac and can withstand temperatures from –55°C to 105°C.

Features that ease operation for the end user also continue to be designed into newer connectors. JAE Electronics (Irvine, California) has launched the SF78 Series compact and slim push-eject tray-type dual nano SIM card connector, which enables installation of two nano SIM cards simultaneously.

Fig. 4: JAE SF78 SIM card connector.

The SF78 Series features a mechanical lock structure that holds the SIM card tray in place without falling out in case the device is dropped. The SF78 series also has a structure that prevents SIM card tray misinsertion and contact breakage during SIM card tray insertion and removal, thus improving ease-of-use for mobile device users.

Japan’s Kyocera Corporation recently unveiled electronic connectors with one-touch locking. The 6810 Series flexible printed circuit (FPC) and flat-flex cable (FFC) connectors provide automatic locking upon full insertion, a key feature to support automated manufacturing and robotic assembly processes. The 6810 Series connectors also offer heat resistance up to 125°C (257°F) for automotive, industrial, and consumer electronics applications.

Fig. 5: Kyocera 6810 Series connectors.

Such improvements in density and performance can be expected to continually appear in the market as new applications arise and new requirements emerge. Connector manufacturers are closely tracking customer needs and responding with both incremental improvements to existing styles as well as the creation of new-style connectors.

For more information on connector technology improvements, read these articles from the AspenCore network of industry publications:

Backplane connectors enhance signal interface, lower insertion loss — The Impulse Orthogonal Direct Backplane Connector System provides high-speed connectivity in a compact size boasting a 2-mm column-to-column pitch.

Press fits, power contacts complement receptacle connectors — TE Connectivity (TE) has added size 20, 16, and 12 power contacts as well as press-fit quadrax contacts to its ARINC 600 connectors portfolio.

High-density connectors save board space in factory automation applications — ERNI Electronics has unveiled a new family of connectors that delivers the signal density, electrical performance, and mechanical dependability required in industrial automation systems.

What Apple’s new connector means for iPhone accessories — Apple unveils new smaller Ultra Accessory Connector (UAC) to replace Lightning and USB.

No More Easy-to-Connect But Hard-to-Test Cables — The widely used, basic crimp connection can now be fully tested in real time using a non-destructive ultrasonic system developed by NASA.

Advertisement

Learn more about Electronic Products Magazine