BY RON DEMCKO, AVX Fellow

www.avx.com

Life-dependent electronics now extend well beyond the implantable medical electronics that traditionally comprised this category. Other demanding applications, including aircraft controls, automotive airbag modules, and advanced driver assist systems (ADAS) — many of which used to rely on human cognition and action — are now recognized as life-dependent electronics systems as well. These systems rely on a vast array of ultra-high-reliability electronics to deliver reliable, life-preserving performance and have spurned the development of a new wave of advanced passive components capable of executing essential, enabling tasks within the various life-dependent end devices that now extend across several electronics markets.

This article will provide an update on two advanced capacitor technologies that provide the peak performance, high reliability, and environmental ruggedness required to enable the ever-expanding swath of life-dependent, harsh-environment automotive, aerospace, and defense electronics.

Flexible-termination MLCCs for harsh environments

Automotive electronics systems are expanding at a staggering rate. The influx of new specifications and designs has elicited the development of myriad enabling devices, including new families of electronic modules designed especially for use in applications with high temperatures, high vibration, and high thermal cycling.

The development of these modules demanded a termination system that could withstand physical flexure and strain resulting from coefficient of thermal expansion (CTE) mismatches between multilayer ceramic capacitors (MLCCs) and a PCB. This capability was achieved by adding a conductive epoxy layer under the final termination finish. The material properties of this layer allow the terminations to withstand up to 5 mm of board flexure with no penalty in terms of increased ESR or ESR instability either over time or due to the effects of environmental conditions.

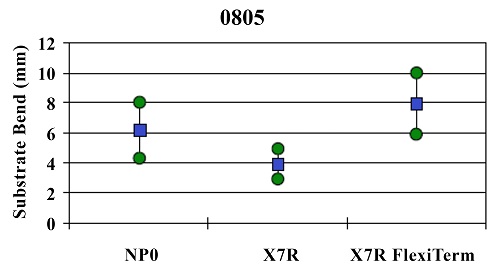

Fig. 1: This chart demonstrates just how well AVX’s FLEXITERM MLCCs — the first flexible termination technology introduced to market — withstand flexure across a 90-mm support span compared to standard NP0 and X7R MLCCs.

Various component families now utilize this flexible termination technology, and they are widely employed in high-reliability applications in which the failure of a single capacitor could shut down the entire system. Examples include low-leakage input capacitors in automotive modules and high-voltage or high-temperature capacitors in power drive snubbers or filters. Since their introduction, the cost of flexible-termination MLCCs has continued to drop relative to the costs of the end system, associated repairs, and replacements, and especially the downtime typically associated with a failed system. These reduced costs, combined with their ability to reliably withstand physical flexure and CTE strain, have resulted in a significant expansion of the types of applications they’re designed into.

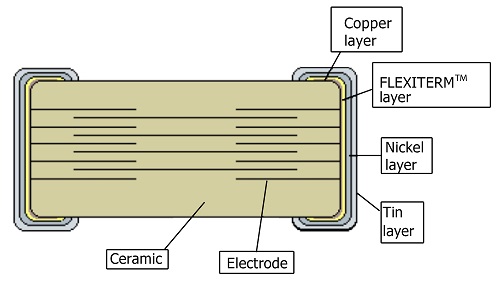

Expanded application employment, especially within the automotive and avionics markets, elicited additional performance demands, including the elimination of the threat of cracked capacitor resulting from board flexure. In response, a product that features two flexible-termination capacitors in series within a single MLCC body was developed to replace the two discrete capacitors generally placed in series at a 90° angle relative to one another in these and other similarly demanding applications.

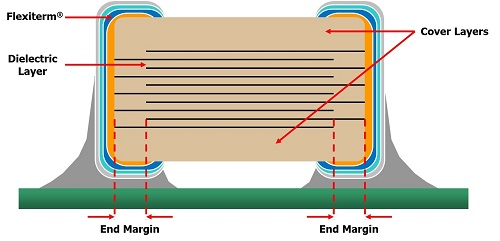

Fig. 2: The internal construction of AVX’s FLEXISAFE MLCC features two flexible-termination capacitors in series within a single case and eliminates the threat of cracked boards resulting from flexure.

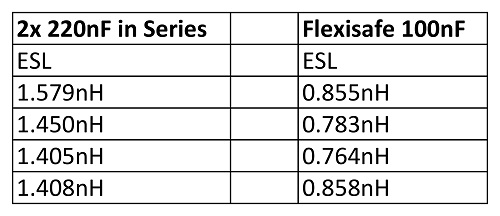

These MLCCs also provide several significant electrical advantages over two MLCCs in series with a 90° orientation, including: higher reliability, lower equivalent series resistance (ESR), and equivalent series inductance (ESL). The electrodes in this design have a favorably decreased dimension relative to two standard MLCCs in series, which effectively minimizes ESR, and eliminate the board traces between two capacitors in a series, which significantly reduces ESL.

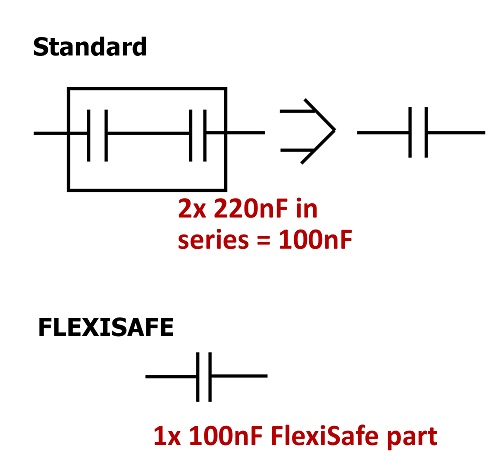

Fig. 3a: An electrical representation of two standard MLCCs in series replaced by a single FLEXISAFE MLCC.

Fig. 3b: This table compares the ESL of 220-nf MLCCs in series to a single 100-nf FLEXISAFE MLCC.

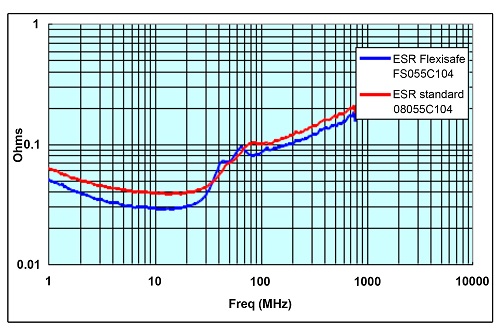

Fig. 3c: This graph compares the ESR of a standard 100-nf MLCC to an equivalent 100-nf FLEXISAFE MLCC.

The fact that these flexible, two-in-one MLCCs reliably exhibit such low ESR and ESL allows them to be used on power pins much more effectively than multiple component solutions. Furthermore, by virtue of having two capacitors in series, these MLCCs deliver the extremely high reliability required for employment in the critical control signal lines of avionic electronics, as well as in the active safety and ADAS of automotive control modules.

ADAS systems, including automated lighting and braking, adaptive cruise control, smartphone connections, and lane and blind spot alerts, are now employed in a majority of new vehicles, and the critical control signal lines in these systems cannot withstand a capacitor failure without causing a complete system shutdown. This can result in a reduced number of redundant nodes voting on the correct interpretation of the data, thus significantly reducing the certainty of the automated system’s response to said data.

High-reliability base metal electrode MLCCs

The new, broader pool of life-dependent electronics applications also includes avionics and military defense, communications, and weapons systems. These systems require small, lightweight components with space-level reliability and cost-effective pricing, which is a fairly tall order. Base metal electrode (BME) MLCCs, which have long delivered higher capacitance values and a wider voltage range in packages up to four times smaller than equivalent precious metal electrode (PME) MLCCs in commercial and automotive applications, are one effective solution capable of satisfying these demands.

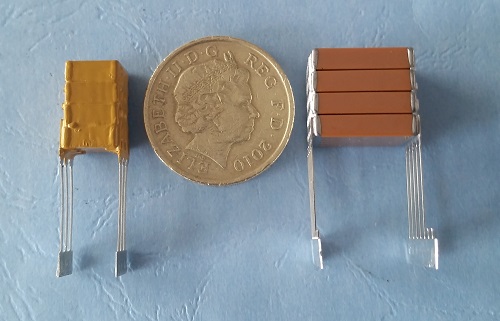

Fig. 4: A space-level, four-stack BME MLCC (left) compared to a space-level, four-stack PME MLCC with equivalent capacitance values and voltage ratings (right).

In recent years, BME MLCCs incorporated significant design and manufacturing improvements that further enhanced their performance to the point of proven PME reliability equivalence while maintaining their comparatively small size, light weight, and low cost. As such, these MLCCs are now approved for use in space-level and other life-dependent, harsh-environment applications.

Design and process improvements responsible for catapulting BME MLCC technology to reliability levels required for life-dependent applications include: reducing the particle size of the X7R bismuth titanite dielectric materials to increase the dielectric strength (V/μ), optimizing the dielectric for the specific process requirements of BME systems, optimizing the thickness of the dielectric layers, and improving the casting, printing, and stacking processes used for extremely thin ceramic layers to enable lightweight components with expanded capacitance values.

Fig. 5: BME MLCCs designed for space-level reliability employ a very conservative design approach. The individual dielectric layers, capacitor cover layers, margin areas, and FLEXITERM layer provide these parts with enhanced protection from overvoltage stress and external environment influences.

BME MLCCs qualified to NASA’s S-311-P-838 specification, approved for use in European space applications and listed on the European Space Association’s (ESA’s) Qualified Parts List (QPL) under the criteria of the European Space Components Coordination’s (ESCC’s) 3009/041 specification, are now available on the market and are suitable for use in any range of size-, weight-, and cost-conscious applications that require high capacitance, a wide voltage range, and stringent reliability standards. With case sizes spanning 0603 to 1812, capacitance values ranging from 2.2 μF to 8.2 μF, and voltage ratings extending from 16 V to 100 V, these next-generation BME MLCCs are enabling a new generation of ultra-high-reliability, life-dependent applications, including radar systems, military defense and weapons systems, and I/O filtering and bulk storage in switch mode power supplies (SMPS) for space and satellite communications and launch systems.

Fig. 6: AVX is the first — and currently only — company recognized as a qualified supplier of space-level BME X7R MLCCs approved for use in U.S. and European military and aerospace designs per NASA’s S-311-P-838 specification, the ESA’s QPL, and the ESCC’s 3009/041 specification.

As electronics continue to permeate nearly each and every aspect of our lives, the list of applications recognized as life-dependent will continue to expand beyond the implantable medical electronics that initially comprised this category, as well as the avionics, aerospace, and ADAS applications that have already extended the parameters of category and challenged engineers to develop new component solutions capable of consistently delivering high-reliability, long-lifetime performance in smaller, lighter-weight form factors with cost-effective pricing.

The development and market introduction of MLCCs with flexible terminations and attractive performance characteristics and BME MLCCs with PME-equivalent, space-level reliability, smaller, lighter-weight form factors, extended capacitance and voltage capabilities, and lower costs have satisfied current component challenges resulting from this expanding electronics category, but manufacturers must continuously work to develop new, improved, and innovative passive components capable of satisfying next-generation design requirements at the board level. The rate of electronic evolution is only speeding up, if anything, and suppliers will always be challenged to deliver better performance in less space at lower costs.

Related article:

Special Report: Supercapacitor market projected to grow from $684.7 million in 2016 to over $2 billion by 2022

Advertisement

Learn more about AVX