By Gary Elinoff, contributing writer

Supercapacitors have it all over batteries in terms of how quickly they can be charged. They needn’t contain the oh-so-volatile element lithium or troublesome liquid electrolytes, so the dangers of explosion and fire are drastically reduced. The problem is energy density; pound for pound, present-day supercapacitors can only hold about 10% of the watt-hours that modern lithium-ion batteries (LIB) can.

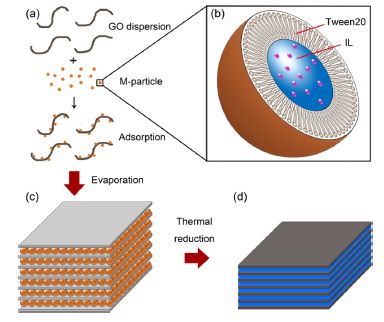

At the University of Waterloo , Professor Michael Pope and his colleagues are working on a way to drastically improve storage capacity. The plates of the capacitor they’ve developed are constructed of graphene and are coated with a special oily liquid salt. Then detergent and water are used to reduce the size of the droplets of liquid salt to a few nanometers. The detergent also serves the purpose of causing the droplets to stick tightly to the graphene.

The nanometer scale of the droplets, microscopically separating layers of plates, makes it possible to deploy a huge number of plates in a given area. And better yet, the droplets themselves serve as the capacitor’s electrolyte, so no separate element needs to be added, which would increase the separation between the plates, thereby avoiding the negative result of lowering the overall capacitance of the device. A description of the work conducted by Professor Pope and his team was released in a press release from the University of Waterloo, and a paper published in the journal ACS Nano describes the work in detail.

Fabricating a supercapacitor. Image source: ACS Nano.

Early uses envisioned for high-density supercapacitors include applications in which really fast charging and discharging are decisive. These include supplying power for high-power lasers and rail-guns, as well as serving as power sources for wearable and mobile devices.

Supercapacitors will also be extremely useful in electrical vehicle braking, which works by converting kinetic energy into electrical energy, thereby slowing or stopping the vehicle. This generates a huge electrical power surge, much of which is now uselessly and wastefully dissipated. Supercapacitors, which can absorb electrical charge far faster than batteries can, reabsorb this previously lost energy, holding it in reserve until it is again deployed to the vehicles motor to put it back in motion.

Research into LIBs for EVs has moved out of the lab and is well-ensconced in corporate research labs such as those of Toyota , which is working on the issues surrounding the charging speed and fire hazards, and they have a large head start over supercapacitors in terms of market penetration. However, these devices can only be manufactured via environmentally dirty processes, while the building of supercapacitors seems to be going down a cleaner path.

In the shorter-term, we may see supercapacitors replace the LIBs in mobile devices such as smartphones. According to Professor Pope, “If they’re marketed in the correct ways for the right applications, we’ll start seeing more and more of them in our everyday lives.”

Advertisement

Learn more about Electronic Products Magazine