By Richard Quinnell, editor-in-chief

The advent of development platforms has unleashed a hailstorm of innovation outside of traditional development channels. With the tricky board layout and system integration issues already solved, innovators simply need to assemble hardware building blocks and write some application code to create a working prototype of their product idea that they can take to crowdfunding sites. But there is a long road between prototype and production, which is where many of these would-be entrepreneurs fall by the wayside. Fortunately, help is on the way.

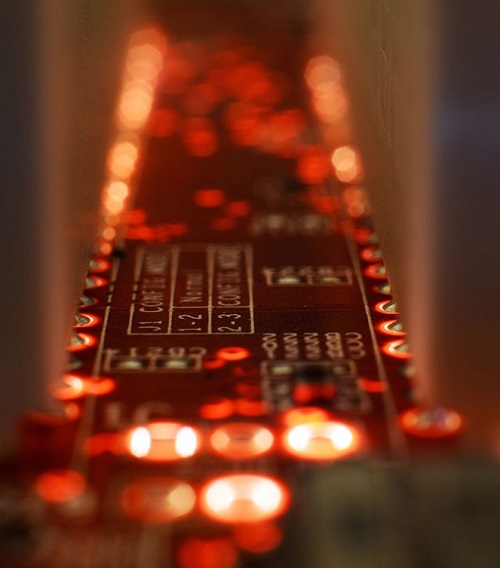

Several technical trends have converged to form a “perfect storm” of innovation in electronic products. First was the advent of microprocessor hardware platforms designed specifically for education and experimentation purposes. The most well-known are the Arduino, the Raspberry Pi, and the BeagleBoard, but many others have also appeared. These platforms provide users with a complete general-purpose processor subsystem configured to allow the plug-in addition of specialty hardware, together with operating system software and simplified development tools for creating application software, all off the shelf and very inexpensive. Thus, most of the heavy lifting of hardware design is already done, removing a major implementation hurdle. The remainder of prototype development is more about concept than technology.

The platform trend, in turn, put substantial embedded processing power into the hands of innovators of many backgrounds outside of electronics engineering. These innovators could now, with minimal electronics knowledge, successfully create working prototypes of their ideas. Innovators with an entrepreneurial bend could use the process to attract investments or early sales to build a business out of their innovation.

The third trend was the advent of crowdfunding websites. Through crowdfunding, entrepreneurs were able to bypass the sometimes arduous process of convincing major investors to back further product development and the risk associated with self-funding. Crowdfunding also provided entrepreneurs with a means of testing the market for their product without first investing in production. A wildly successful funding campaign indicated a potentially strong market and also financed further development, while a failed campaign indicated a poor market, avoiding such costs.

Together, these three trends have allowed many innovative products that might not otherwise have seen the light of day to come before potential customers for consideration and pre-purchase. While this process has resulted in some notable successes that thrived and grew, there were many successfully funded campaigns that failed to make the transition from concept to production. Making something that works on the bench, it turns out, is still a far cry from making something that can be reliably manufactured and work in the field. The productization of a design is a skill that novice innovators seldom possess.

At CES 2018, however, help for these novices was on full display in the Eureka Park. The two major crowdfunding companies — Indiegogo and Kickstarter — were highlighting examples of their recently introduced collaborations with electronics parts distributors that aim to help innovators bridge the gap between prototype and production. Indiegogo has joined forces with Arrow to create the Arrow Certification Program, while Kickstarter is working with Avnet to offer the Hardware Studio. Both collaborations offer developers help with pre-production planning and engineering, crowdfunding product launch, and engagement with manufacturing services. The goal in both cases is to help guide and support innovators in their journey from concept to market.

While the overall goals are the same, however, there are differences in what these programs offer. Hardware Studio, for instance, offers online educational resources and access to tools such as Dragon Innovation’s Product Planner. In addition, the collaboration’s Connections campaign provides engineering advice, hardware discounts at Avnet, an opportunity for promotion on Avnet’s Hackster.io and Element14 sites, and engineering support with things like component sourcing, design-for-manufacturing reviews, BOM optimization, factory selection, production oversight, and compliance certification.

The Arrow Certification Program offers similar services, including engineering consultation and design reviews, free access to online BOM and OrCAD design tools as well as IBM’s Watson and IoT cloud services, and 10% off of Arrow.com purchases. Program participants also have the technical support of industry giants like Analog Devices, IBM, and TE Connectivity to expand on what Arrow provides.

The program goes further, however, when a design has been program-certified by demonstrating that it meets trust and safety requirements and is feasible for manufacturing. Products earning the Arrow Certified Technology designation gain marketing exposure and support, assistance with volume pricing, procurement, and warehouse services, free use of the Silicon Expert components search service, a $1,000 rebate on Arrow components and services, and the possibility of receiving Arrow funding during their Indiegogo campaign. Arrow provided over $1 million in such funding during 2017.

In addition, projects that attain certification gain enhanced market credibility. Possession of the Arrow Certified Technology badge lets potential investors know that the design has been verified as manufacturable, removing one of the key risks of supporting crowdfunded projects. Such projects are less likely to fail to make the transition from prototype to production.

With either program, the collaboration between crowdfunding sites and electronics distributors will prove a boost to the innovation wave sweeping the electronics industry. The programs help to reduce the cost and complexity of taking an idea all the way to market and should help improve the success rate of popular crowdfunding campaigns. Like the advent of hardware platforms and open-source software, they’re another big step toward the democratization of electronic product design.

Advertisement

Learn more about Electronic Products Magazine