By Richard Quinnell, editor-in-chief

There is a groundswell of activity in the microcontroller world to bring machine-learning artificial intelligence (AI) to the network’s edge. But the computational requirements of running algorithms such as convolutional neural networks (CNNs) can be fairly demanding of power. Fabless semiconductor vendor GreenWaves Technologies has addressed that issue with its release of a new processor that applies AI to sensor readings to help distill data to reduce traffic.

GreenWaves announced at Embedded World this week its GAP8 application processor, an eight-core computational cluster that has been optimized to handle video- and audio-processing algorithms as well as CNN. The processor also has a core dedicated to communications, control, and sensor data pre-analysis. Target applications for the device include object and face detection, vibration analysis, and keyword spotting in audio data streams. Based on the open RISC-V architecture , the GAP8 is part of Europe’s parallel ultra-low-power initiative (PULP), designed to increase processing performance at the edge in battery-powered IoT applications such as sensing.

The advantage of having AI capabilities at the edge, GreenWaves vice president for business development Martin Croome told EP in an interview, is that it can dramatically reduce the amount of data flowing between the device and cloud services. The AI allows the edge device to classify the data that it collects instead and send only the classification results rather than the raw data. In a people-counting application, for instance, giving the IoT camera the ability to distinguish people from other objects in field of view can eliminate the need for sending video information to the cloud. Instead, the device simply needs to send the counts that it makes, reducing data rates from kilobytes per second to a few bytes per day. Similarly, a simple voice-control application needing only a handful of command words can operate almost entirely within the processing capability of edge devices such as the GAP8.

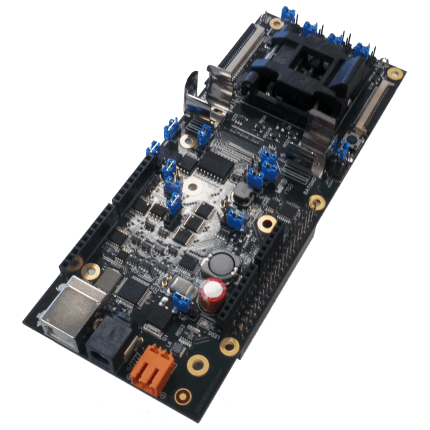

The Gapuino development board will provide an opportunity to quickly begin working with AI at the edge using the GAP8 processor. Image source: GreenWaves Technology.

The processor’s architecture utilizes a shared instruction cache (SIMD) that feeds nine identical processor cores. One core serves as the fabric controller and activates the eight other cores to provide parallel processing as needed. The controller is able to coordinate the resulting operations so that each core can run a task independently until completion, then have the controller assemble the results for use in the next instruction. Croome estimates that the processing achieved is nearly 20 times better than traditional DSPs for AI functions.

Because the GAP8 and its supporting software and development tools are built on open platforms, the cost of this performance can be quite low. There are no royalties or licensing fees involved, and the company’s development investment only needed to be spent where they could add value rather than building the foundation, so the company expects to be offering the chip for $5 in 100K quantities. As a result, the company estimates, something like machine vision and voice control of consumer robots could be done with hardware costing less than $15.

The processor’s SDK has been available since December, and GreenWaves will be rolling out a development board — the Gapuino — in April, allowing developers to quickly get started on product development. The SDK supports multiple real-time operating systems (including mBed) and includes an auto-tiler to help parallelize application code and data streaming. There is also a code generator for common AI algorithms such as CNN and software to bridge from TensorFlow AI descriptions to Gap. The base development board can be pre-ordered for €100, and there are both sensor interface and image plug-in expansion boards available.

Advertisement

Learn more about Electronic Products Magazine