If someone was to develop a “forever battery,” chances are good that power efficiency would fall much lower on the priority scale for electronics engineers than it does today. But despite countless research investments, no such battery is in the offing. Instead, in the real world, designers must do everything possible to limit power consumption. This is especially true for the IoT, says Tektronix Applications Engineer Seshank Malap, who sees the IoT spurring a wave of power-related innovation both in design and test and measurement.

Malap has worked in the power industry for the past six years designing and testing power semiconductors, UPS systems, automotive battery chargers, and automotive motor drives. We talked to him about the changes that he sees occurring in the industry from both design and test-and-measurement perspectives.

Q: How is the rise of the IoT impacting the power industry?

A: The need for more efficient power utilization has been growing exponentially over the past decade due to the need for being connected all the time. With the rise in the IoT, an increasing number of physical objects are being wirelessly linked together. This is leading to huge numbers of IoT sensors and devices that need to stay on and transmit day in and day out so they can collect and stream vast amounts of data. This requires a lot of power.

The continuous always-on aspect of IoT devices and the fact that most of them are battery-operated demand new solutions to power management. Power engineers are being asked to push the limits to achieve super high-power efficiencies and ultra-low consumption in order to squeeze out as much power as they can from a source. Power efficiencies in high 90s and power consumption and sleep mode currents in nano- to pico-amps are becoming quite common.

Meeting these requirements is driving innovation across the entire power ecosystem, including the emergence of new test-and-measurement technologies.

Q: What challenges are facing engineers in the IoT era?

A: There is no question that the engineering and testing challenges brought on by the IoT are immense. Engineers must figure out how to squeeze more power out of these new devices and, more importantly, how to actually test and validate that designs will work in the real world. Similarly, the need for super-high efficiencies and small form factors in power designs has pushed engineers to use higher and higher switching frequencies and smaller component packages. This has led to the development and use of new wide-bandgap switching technologies such as gallium nitride (GaN) and silicon carbide (SiC), which can switch significantly faster than traditional silicon devices and provide a compact package. This comes with its own set of very difficult testing challenges.

All in all, however, these trends are exciting for the future of power designs and are one of the key innovation areas in the electronics industry. I think that we will see some awesome progress out of these changes. But it will require a lot of work from engineers to solve the aforementioned challenges. Hopefully, those of us in the test-and-measurement space can help them along the way by at least making their testing jobs easier and (ahem) more efficient.

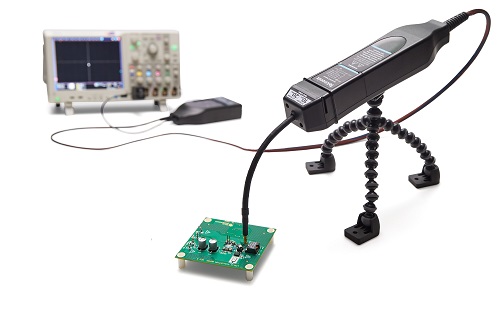

Demand for power efficiency in IoT designs has spurred innovation in power conversion design, which has, in turn, spurred improvements in test equipment design, such as this Tektronix IsoVu probe with a million-to-one common mode rejection capability. Image source: Tektronix.

Q: What are some other trends and challenges in this space?

A: Apart from the challenges involved with super-high efficiencies, smaller form factors, and ultra-low power consumption, there’s a flood of ever-changing regulatory standards that are pulling power design in the direction of even more efficiency. For example, the U.S. Department of Energy recently came out with its Level VI efficiency standard for external power supplies (EPSes) for consumer products, adding more efficiency requirements than ever before. Not to be outdone, the European Union has released the Code of Conduct (CoC) Tier 2, which is even more stringent than the DoE’s Level VI.

The standard bodies are going for higher efficiencies, which means more testing for the same kinds of devices, especially for power supplies. These requirements are true for pretty much every vertical industry, so the impact is pervasive. And the impact isn’t limited to power supplies or battery chargers; a recent standard just came out for LED drivers pushing for electric as well as electric-to-optic conversion efficiency.

The standards are, in many ways, a designer’s worst nightmare. Because the standards (and others like them around the world) are living documents, engineers must be constantly ready to push for higher efficiencies. Every four years or so, the standards go to that next level of power efficiency and lower standby power consumption requirements. In addition to being efficient when it’s running, a device must demonstrate really, really low power consumption when it’s not doing anything.

Q: What role does test and measurement play in enabling innovation in this segment?

A: To understand the role of test and measurement, it’s important to understand key trends and challenges. As mentioned earlier, getting higher efficiencies requires a lot of innovative design methods, one of which is going to higher switching frequencies. This explains why wide-bandgap power devices are becoming quite popular in new power electronic designs. But these devices come with their own testing challenges. On one hand, you need extremely high bandwidths, and on the other hand, you need very high sensitivity as the switching and gating signals become more critical and sensitive. High frequency of operation also raises the need to measure more signals at the same time to optimize timing and duty cycle to get the best out of the design.

The need for testing and evaluating at the component level also increases significantly when deploying new technology such as GaNs and SiCs. The devices need to be tested for breakdown up to thousands of volts and, at the same time, vetted for leakage currents that can be as low as femto-amps. Robust testing of these devices, all the way from the wafer to the package parts, becomes quite critical given the demanding designs that they are deployed in.

At the system level, the needs for testing for extreme high efficiencies, smaller incremental design changes to meet the efficiency requirements, and testing accurate power consumption in all operating modes are becoming quite crucial.

It’s safe to say that testing accurately at far more test points in the system and at all stages of design is becoming more important than it used to be. The testing tools and techniques of old are simply not sufficient for the changing trends facing power designers.

Q: Can you talk a little more about the new materials?

We hear a lot about wide-bandgap devices. They’re basically GaNs and SiCs. SiC is driven by higher power needs and thermal stability, and GaN is driven by faster rise times and fall times. These trends introduce new complexities into power conversion circuits with faster switching speeds (need to measure the floating Vgs and Vds measurements in any H-bridge topologies) and more sensitivity for gate threshold voltage and timing. Also, because of the high frequency of operation, more signals need to be looked at simultaneously. All of this requires new test tools and new methodologies to optimize performance for a given application and to ensure reliability.

Q: How is the test-and-measurement industry helping designers address these new requirements?

A: The industry, overall, has done a good job of supporting the power industry, and designers can find instruments and software solutions for power electronics design that cover everything from component testing to final compliance testing of a finished product. Specific technologies range from source measure units (SMUs) and parametric testers at the component levels to oscilloscopes and power analyzers, as well as tools such as low-cost spectrum analyzers for conducting EMC pre-compliance testing. Day-to-day instruments such as sampling digital multi-meters are now available that can resolve down to pA sleep currents and still show pulsing currents up to 1 MHz, making it possible for engineers to characterize DC power profile in all operating states for complex IoT sensors and, in turn, maximize battery life.

Advertisement

Learn more about Tektronix