By Warren Miller, contributing writer

A team of researchers at the University of Illinois at Urbana-Champaign have devised a new kind of heat switch, a mechanism by which the flow of heat into an electronic system can be shut off or turned back on with the push of a button. The flow of heat can significantly affect the long-term performance and reliability of mechanical and electrical components, including everything ranging from laptops to cellphones to automobile engines. If the new UI heat switch can be reproduced in commercial electronic products, it could become a ubiquitous part of modern technology.

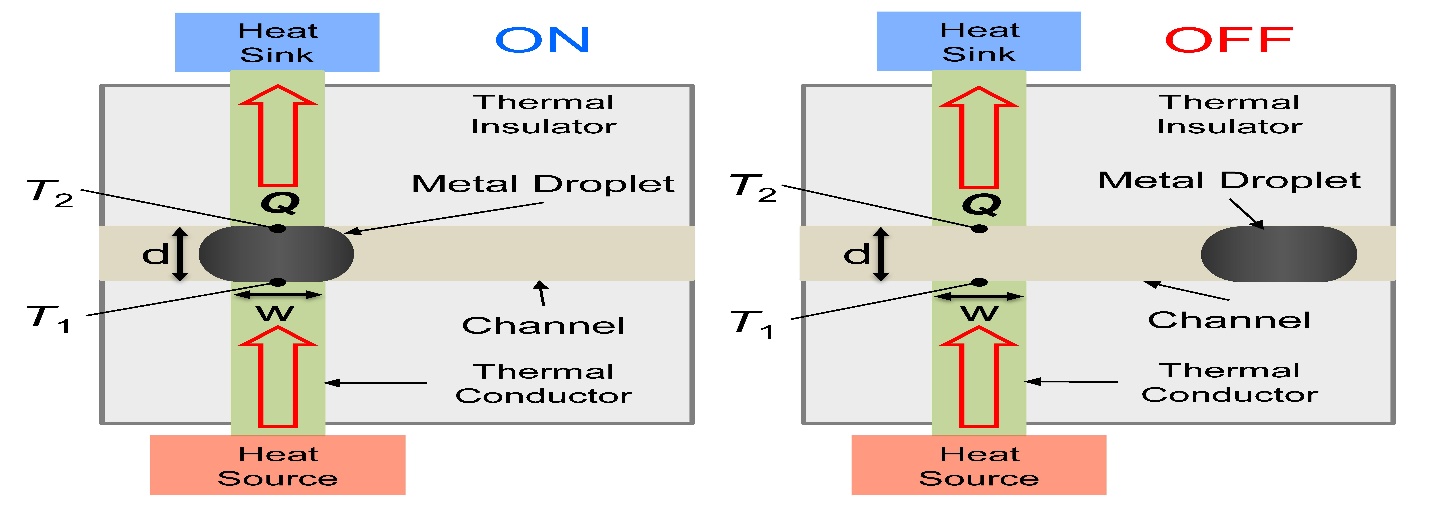

At this point, you may be asking yourself, “What’s the big deal? I’ve got a thermostat in my house/apartment; isn’t that just a switch that turns the heat on and off?” Well, yes and no. The thermostat tells your home’s internal heating system when to operate and for how long, but it doesn’t cut off the flow of heat so much as it stops producing it. The UI heat switch can instantaneously stop the flow of heat from one place to another, a key factor in protecting electronic systems from overheating. In order to do this, the researchers used a small droplet of liquid metal as a heat conductor.

“The technology is based on the motion of a liquid metal droplet,” said Nenad Miljkovic, the project co-leader and Assistant Professor in the Department of Mechanical Science and Engineering at UI Urbana-Champaign. “The metal droplet can be positioned to connect a heat flow path or moved away from the heat flow path in order to limit the heat flow.”

Image source: Illinois University.

The UI team created a model for the technology based on common electronics systems, placing a power source to generate heat on one side of the switch and a liquid cooling element on the other side to extract the heat being generated. When the metal droplet was placed in between the two elements, the researchers were able to capture heat at a rate of 10 W/cm2 . When the metal droplet was removed, the flow heat decreased by a factor of almost 100x.

Perhaps the most interesting application of this technology could be for directing heat to different “destinations.” The switch could cut off heat transport from one destination and send it to another. This could improve and optimize cooling by sending heat “pulses” to different heat sinks, thus allowing them time to dissipate the heat via convection. Pulses could be directed and timed to optimize the flow of the conductive medium to ensure that heat-generating electronic components stay as cool as possible. Heat flow could also be directed based on which components are generating heat, making the system much more adaptive and responsive to heat generation variations as different parts of the system are active.

Not surprisingly, William King, another project co-leader and the Andersen Chair Professor in the Department of Mechanical Science and Engineering, plans on developing a prototype by incorporating the heat switch into a circuit board. If successful, this technology could fundamentally change the way that electronic systems manage heat.

Advertisement

Learn more about Electronic Products Magazine