By Eric Rice, National Marketing Manager, Applied Motion Products

Open-loop stepper motors have held a prominent position in automation applications over the years due to their simplicity, excellent positioning, and low cost. However, as manufacturers utilize faster machines to increase throughput, open-loop steppers are being challenged. They may need to yield ground to closed-loop stepper systems, which tests show provide greater performance advantages than their open-loop counterparts.

High-throughput production machinery requires high-performance motion control. As such, motors using closed-loop feedback and advanced control technology create more torque, provide faster dynamic response, and exhibit higher operating efficiency than open-loop systems. In fact, closed-loop stepper systems create peak torques up to 50% higher than the rated holding torque, which enables higher acceleration rates. Closed-loop also means that the motor only draws current when it needs it, so such step motors run cooler and more quietly than their open-loop counterparts. Results from the following tests comparing closed-loop versus open-loop step motors support these claims.

Meeting higher acceleration requirements

High-throughput processes require motors to start and stop quickly. A motor’s available torque determines how quickly it starts and stops. Closed-loop step motors produce more torque and, therefore, accelerate and decelerate faster.

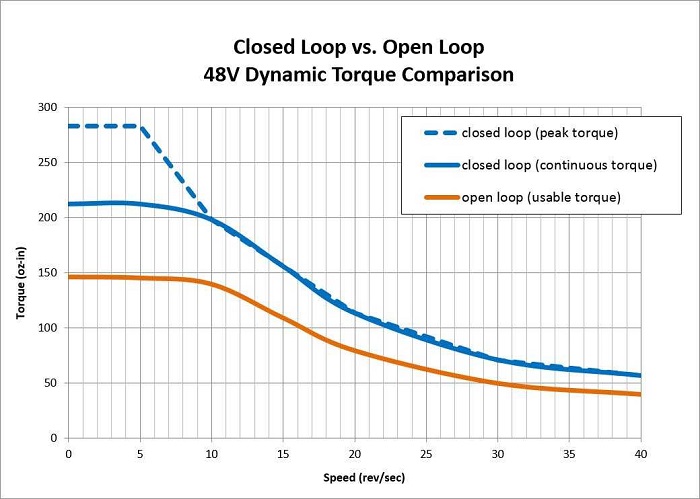

Results from a comparison test that Applied Motion Products conducted between a closed-loop versus open-loop stepper system (Fig. 1 ) indicate that closed-loop steppers not only excel in acceleration and efficiency but operate at much cooler temperatures and with less audible noise. The test utilized equally-sized open-loop and closed-loop stepper systems with an external inertial load of 460 g-cm2 to compare acceleration. Curves show the peak and continuous torque of a closed-loop stepper system and the useable torque of a typical open-loop stepper system.

Fig. 1: A torque comparison of a closed-loop versus open-loop system under the same operating conditions.

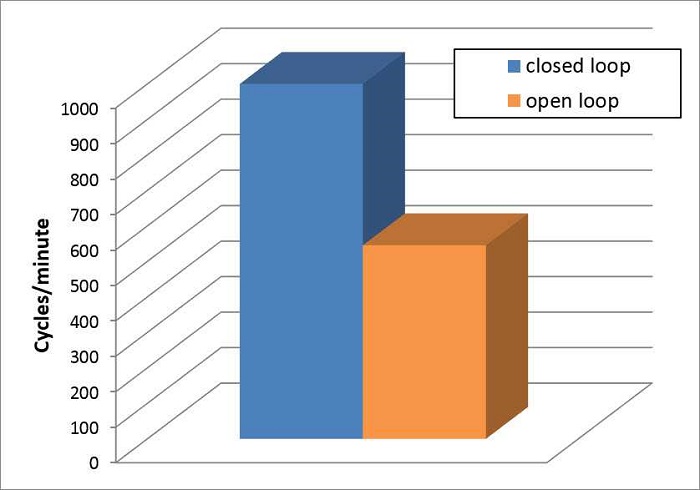

Torque, in turn, empowers acceleration. The open-loop system achieved a maximum acceleration rate of 1,000 revs/s2 up to 10 revs/s. The closed-loop stepper system produced much higher peak torque and higher torque at higher speeds than the open-loop stepper system, driving the same load at an acceleration rate of 2,000 revs/s2 and to a speed of 20 revs/s. Move duration also reduced to 60 ms. The faster move achieved nearly double the cycles/minute (see Fig. 2 ).

Fig. 2: Greater acceleration in the closed-loop system allows faster moves, achieving nearly double the cycles/minute.

Lower energy needs mean lower power consumption, less heat

Typically, increasing the speed and throughput of a machine means consuming more power. In the case of closed-loop stepper systems, however, the opposite is true. Closed-loop step motors actually consume less energy and waste less power as heat than their open-loop counterparts.

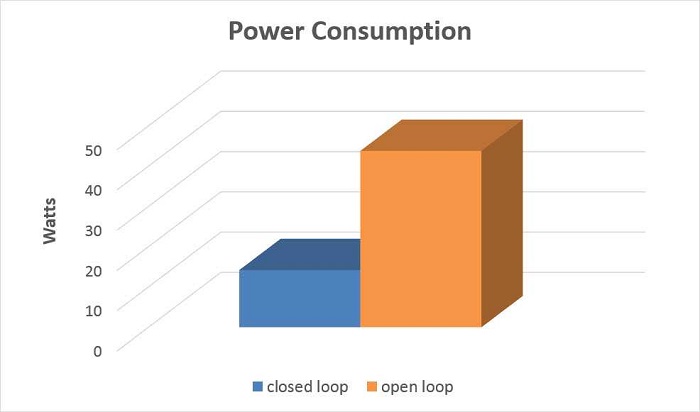

A side-by-side comparison using the same operating parameters measured the relative efficiency of an open-loop versus closed-loop stepper motor system. The test implemented the same move profile (see parameters listed below), load inertia, and rotor inertia for both systems. Both operated from a 48-Vdc power supply.

Move parameters included:

- Accel = 100 revs/s2

- Decel = 100 revs/s2

- Distance = 5 revs

- Speed = 10 revs/s

- Dwell time = 0.1 s

The test results (Fig. 3 ) show that the average power consumption of the open-loop stepper system was 43.8 W, while the closed-loop stepper system consumed only 14.2 W.

Fig. 3: The closed-loop stepper system requires less current consumption than an open-loop stepper system.

This reduced power consumption also means that less energy has been wasted as heat. Not only is this an energy savings, it improves reliability and simplifies thermal design. Heat affects the operation and life of machinery. Maintaining cool operating temperatures is often challenging for open-loop steppers that run at currents higher than necessary to produce the torque to run a motor.

The key to the energy reduction is the control that a closed-loop system provides. When setting the drive for a motor’s rated current, open-loop steppers continuously put that current into the motor whether or not it requires all the torque. When the load is not demanding torque, the additional current is lost as heat. Closed-loop step motor systems automatically reduce current to the motor when the load is not demanding torque. In fact, they only apply the current needed to drive the load.

A test that Applied Motion Products conducted compared the differences between an open-loop and closed-loop stepper system when commanded to continuously execute the same move. Both motors drove inertial loads of 460 g-cm2 , which is equal to their rotor inertia.

Move parameters included:

- Accel = 100 revs/s2

- Decel = 100 revs/s2

- Distance = 5 revs

- Speed = 10 revs/s

- Dwell time = 1 s

After running the test for 30 minutes, the case temperature of the open-loop stepper system rose to 76°C, while the closed-loop stepper system ran at a cool 36.9°C.

Reduction in noise

One feature of motors that many do not think about is the sounds that they make. Noisy machinery can be disruptive and adversely affect worker health and safety. Open-loop step motors make audible noise due to the high electrical frequency and rapid flux changes in the stator teeth and because they operate the motor at full rated current regardless of load. As closed-loop systems supply the motor with just enough current to control the load, its acoustic levels are lower. In fact, closed-loop systems provide a reduction of 10 dB in noise due to less current in the motor windings.

Based on these tests, results indicate that closed-loop step motor systems provide a better option for high-throughput machines due to faster acceleration, quieter operation, and higher overall system accuracy due to the elimination of stall conditions. Available in the same NEMA frame sizes as open-loop motors, they easily replace existing open-loop motors in both new and existing applications.

Advertisement

Learn more about Applied Motion Products