By Warren Miller, contributing writer

Robots can be designed to perform a variety of functions from assembling automobiles to performing simple surgeries. A team of researchers at Ben-Gurion University of the Negev have developed a robotic arm that can potentially repair satellites while still in orbit — or pick apples off a tree.

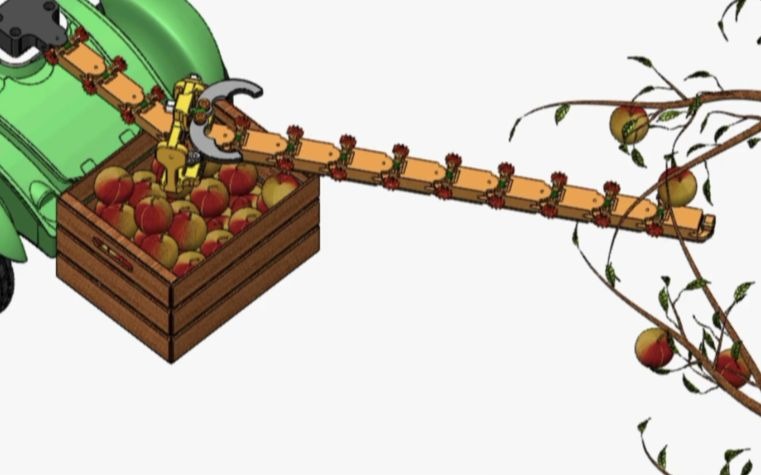

The minimally actuated serial robot’s (MASR’s) design is similar to that of a traditional snake robot except that, while snake robots are typically equipped with several motors, the Ben-Gurion mechanism only employs two. One motor runs up and down the length of the arm, while the other rotates the joint that requires flexing. The arm has multiple links all controlled by a single motor, but only one link can be actuated at a time.

“This unique minimalistic configuration, which can be applied to any serial robot with two or more links, reduces weight, size, and cost,” said David Zarrouk, head of BGU’s Bio-Inspired and Medical Robotics Lab. “This robot is easy to operate and likely has a number of applications including space, agriculture, and industry, as well as search and rescue.”

While Zarrouk admits that speed isn’t the arm’s strong suit, moving slowly isn’t much of a drawback in space. Its lightweight design, however, could make it ideal for space applications ranging from satellite construction and repair to docking and refueling.

Image source: Ben-Gurion University of the Negev.

Speed will be an issue in potential agricultural applications, however. According to Yael Edan, the head of BGU’s ABC Robotics Initiative devoted to cultivating robotic systems based on human and animal archetypes, the arm would have to pick at least one fruit every three seconds to make a commercial impact. While the BGU team hasn’t tested its speed in this regard as yet, Zarrouk pointed out that because of the arm’s extremely light weight, a vehicle could be outfitted with more than one (or even several) arms to increase efficiency. Researchers have also given thought to adding additional motors while still maintaining the arm’s light weight and basic design.

The idea of moving the motor to the spot where it is needed seems to be a useful innovation and ripe for a variety of applications. Consider situations in which a robot with many legs might need only a few motors that moved up and down the leg to the location where the leg needed to flex — could multiple motors be moved to the same location to provide additional power? Could multiple motors provide built-in redundancy so that if a motor failed, it could be discarded or perhaps kicked off the leg by a replacement motor? The possibilities are staggering.

Advertisement

Learn more about Electronic Products Magazine