By Warren Miller, contributing writer

As chips and electronic systems continue to cross thresholds of higher and higher performance, they need to manage an inevitable byproduct: heat. As more traditional cooling methods prove less effective, chip designers and manufacturers are looking for efficient, cost-effective solutions to their cooling problems. Imec, an international collaborative research hub, recently introduced an innovative new cooling technique that could provide an answer.

Current cooling solutions rely on heat exchangers and spreaders attached to the backs of chips to distribute the heat evenly along the surface of the chip. This is an important consideration — any temperature differential degrades performance and long-term viability, making direct cooling of the chip a less-than-ideal solution.

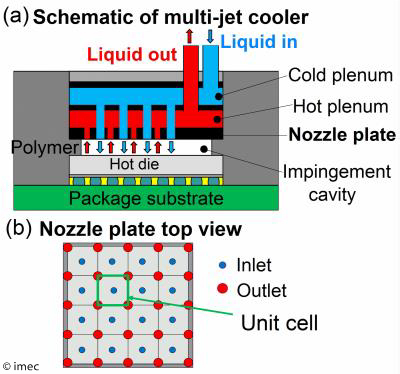

Liquid coolants must be distributed evenly across and perpendicular to the chip’s surface to maintain an equal temperature and to cut down cooling time — a process commonly performed by impingement coolers. These impingement-based cooling systems have typically been silicon-based, making them cost-inefficient to produce, said Imec.

Imec’s solution to this persistent problem is a polymer-based impingement chip cooler produced by a high-resolution stereolithography 3D printer that features nozzle sizes of only 300 µm. The nozzle pattern design can be customized to suit the specifications of a chip design. By using a 3D printer, the entire structure can be printed as a single part, significantly lessening both production time and costs, said Imec.

Image source: Imec.

The new design has outperformed industry standards by a significant margin. While more traditional cooling systems and thermal interface materials produce a temperature increase of anywhere from 20°C to 50°C, the Imec impingement cooler boasts a temperature increase of less than 15°C per 100 W/cm2 at a coolant flow rate of one liter per minute and delivers a pressure drop as low as 0.3 bar. In addition to its higher performance and lower cost, the Imec system is also physically smaller than existing solutions, making it more in line with the ever-miniaturizing world of chips and electronic systems.

Liquid cooling isn’t a new concept, however. The first big mainframe computers from IBM and Cray had complex liquid cooling systems that rivaled the complexity of the electronics. In fact, Cray had more patents on cooling innovations than on electronic ones for its biggest computers. These cooling systems took up much more space than the innovative approach that Imec has identified.

More efficient cooling means better, longer-lasting performance, which means that Imec’s design could become the industry standard in short order. Cooling is a central issue in high-resolution video and graphics systems, such as multimedia or augmented reality/virtual reality (AR/VR) platforms. If the polymer-based impingement cooler can find its way into those markets, it could become the proverbial pot of gold at the end of the rainbow.

Advertisement

Learn more about Electronic Products Magazine