By Giovanni Campanella, Systems Engineer, Factory Automation, Texas Instruments

Cost, safety, availability, and reliability are the main reasons why key industrial players are investing in predictive maintenance. Predictive maintenance allows factories to monitor the condition of in-service equipment by measuring key parameters like vibration, temperature, pressure, and current. Such monitoring requires connected smart sensors featuring a high-speed signal chain, powerful processing, and wired and/or wireless connectivity.

The current trend is leaning toward wireless connectivity because it is possible to cover remote locations and does not add extra wiring costs. Wireless connectivity converts existing equipment into smart equipment (rather than replacing it), enabling users to plan maintenance based on actual needs and increasing productivity and efficiency. That is the ultimate goal of Industry 4.0.

Why predictive maintenance?

According to the U.S. National Response Center, it costs approximately 50% more to repair a failed asset than if the problem had been addressed before failure.

In addition, if an asset such as a motor fails in an unpredictable way in a factory environment, it could hurt an operator working with it, possibly resulting in a lost-time incident, fines, or audits.

Finally, an unavailable asset can slow down or even stop production, causing the loss of millions of dollars and, in some cases, even customers.

Cost, safety, availability, and reliability are the main reasons why predictive maintenance is fundamental in Industry 4.0 , a trend whose goal is to make factories more productive, efficient, and flexible. A leading solution for predictive maintenance is condition monitoring.

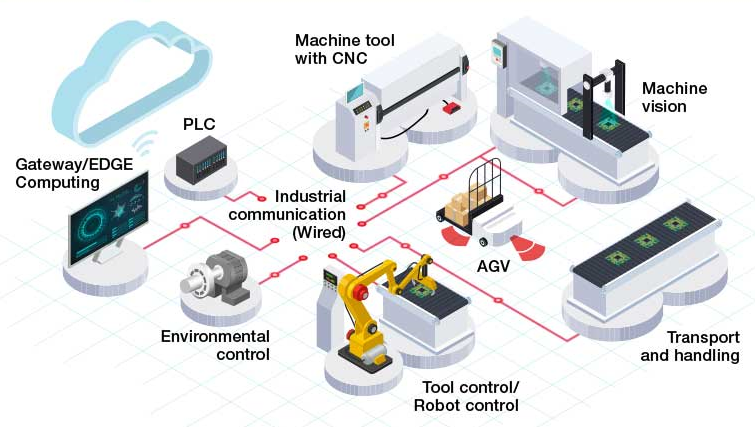

By monitoring the status of an asset and predicting its failure, factory workers will be able to replace or repair the asset before it breaks. This proactive approach avoids downtime and increases the mean time between failure (MTBF), which improves the production process and makes it more efficient. You can see an example of a production cell in Fig. 1 .

Fig. 1: Example of a production cell.

What is predictive maintenance?

Developing an effective monitoring system requires both hardware and software components, including condition monitoring sensors, gateways and modules that will handle data processing and transmission, and a secured cloud server to act as the software component and handle data storage and data analytics.

The sensor is the first and most important component of the entire system. Vibration, temperature, pressure, and current are only some of the parameters that can indicate equipment status. A low-power and small-footprint solution with high-resolution, high-speed conversion is needed for the condition monitoring sensor to obtain reliable data, which, when processed, can determine the machine health.

The processing part, which may entail efficient, scalable fast Fourier transform (FFT) calculation to predict potential equipment failures, can either occur at the sensor level or be outsourced to a gateway, module, or the cloud. It is important to keep in mind that edge processing done directly in the field will reduce system power and lower network bandwidth by taking some of the processing capabilities away from the control or operator level (the “core”) to the field level (the “edge”).

From the sensor, data will be transmitted via wire to either a gateway or module through standard interfaces such as 4–20 mA, Highway Addressable Remote Transducer (HART), IO-Link, or industrial Ethernet while leveraging the existing network or using other interfaces like Integrated Electronics Piezo-Electric (IEPE) for accelerometers based on a piezoelectric measurement principle.

Although a condition monitoring gateway allows data communication between multiple wired or wireless sensor nodes to a central condition monitoring system, a condition monitoring module has the same features as the gateway in addition to processing capabilities.

A wireless network such as a wireless mesh network (like Wireless HART), a wireless point-to-point network (like IO-Link wireless), or a star network (like sub-1 GHz) would be the best solution to transmit data when equipment is in a remote location or when using an existing wired network is not possible or not convenient.

Mesh networks make radio systems more reliable by allowing radios to forward messages to other radios. For example, if a node cannot send a message directly to another node, the mesh network forwards the message through one or more intermediary nodes.

Other protocols such as Wi-Fi or Bluetooth are used for configuration purposes, allowing operators to interact with the equipment wirelessly instead of through a standard touch panel.

From the gateway, data will be transmitted either to a condition monitoring module, a factory control system data monitor, or to a secured cloud server. This is the last chain link where, based on the monitored data, a decision would be taken if equipment needs to be maintained or not. However, the ability to accurately interpret and communicate this data with a deep-learning algorithm is essential for system reliability. Indeed, a condition monitoring solution with deep learning would reduce the human error and makes predictive maintenance solutions smarter and more effective.

How predictive maintenance is implemented?

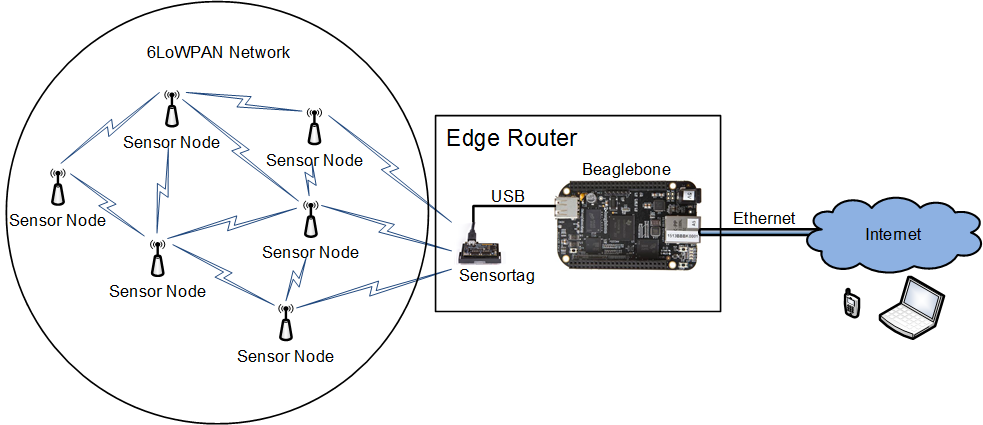

Texas Instruments (TI) implemented predictive maintenance in one of its factories by equipping several vacuum pumps with a sensor node, a reference design developed by TI, which measures and collects data from the pump, such as temperature, motor current, nitrogen flow, and water flow, transmitting the data to the internet through a gateway as depicted in Fig. 2 .

TI can easily access the data through the internet for continuous monitoring and analysis, giving operators of the pumps insight into operating conditions. For example, independent of the usual maintenance schedule, operators could identify defective equipment that might cause a system shutdown and replace it before any damage occurs.

Fig. 2: Example of a wireless mesh network for predictive maintenance.

With this practical example, TI has been able to upgrade its own factory to a smart factory enabling predictive maintenance by monitoring the condition of in-service equipment.

Indeed, predictive maintenance is one of the main factors that will drive the Fourth Industrial Revolution, making factories more efficient and productive, reducing unplanned downtime, improving reliability, and saving maintenance costs.

Advertisement

Learn more about Texas Instruments