By Daniel West, Field Application Engineer, AVX

To date, the evolution of electronic components such as capacitors, resistors, diodes, and RF filters has trended toward continued miniaturization and, where possible, added functionality. Material advancements, alternative terminations, and improved processing technologies have led to the development of even smaller, ultraminiature capacitors. Ultraminiature multilayer ceramic capacitors (MLCCs), for example, were achieved through material advancements including smaller particle size, thinner dielectrics, and alternative termination technologies.

Capacitor size reductions can also be achieved by increasing the functionality of a same-sized capacitor with fewer capabilities. Physical miniaturization can pose significant component design challenges, and pushing the limits of electronic component functionality can be even more difficult.

Improvements across multiple scientific fields have contributed to these designs, but the most notable progress includes purer ceramic, tantalum, and thin-film materials and improved processes, such as closed-loop manufacturing (CLM). The improved ability to remove impurities from raw materials and process them using CLM techniques plays a key role in component capabilities, reliability, and electrical and thermal stability.

These shifts have enabled extremely accurate computer-aided design (CAD) models, which can be translated into marketable, real-world parts. Inventive combinations of other techniques, including packaging designs, fine copper terminations, and photolithography have further expanded components for miniature circuit designs.

Key drivers

OEMs and their electronics designers are looking for miniaturized parts to optimize circuit and system performance, satisfy physical design requirements, and improve product aesthetics. Smaller parts also typically operate at higher speeds with lower parasitics, making them more compatible with integrated circuit (IC) advancements.

Miniaturized capacitor use has evolved from very specialized applications to more mainstream markets. Some highlights include:

- Defense: The Torpedo Data Computer (TDC) was one of the first electromechanical analog computers small enough to fit within a submarine and was used during WWII (1939–1945) to automatically track targets.

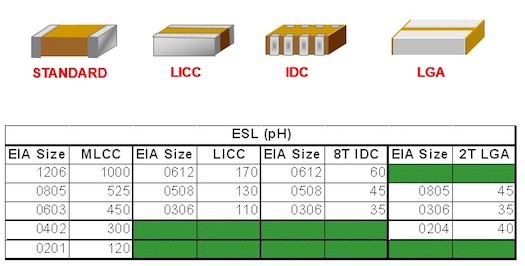

This chart depicts decreasing parasitic inductance (ESL) by case size and packaging type.

This chart depicts decreasing parasitic inductance (ESL) by case size and packaging type.

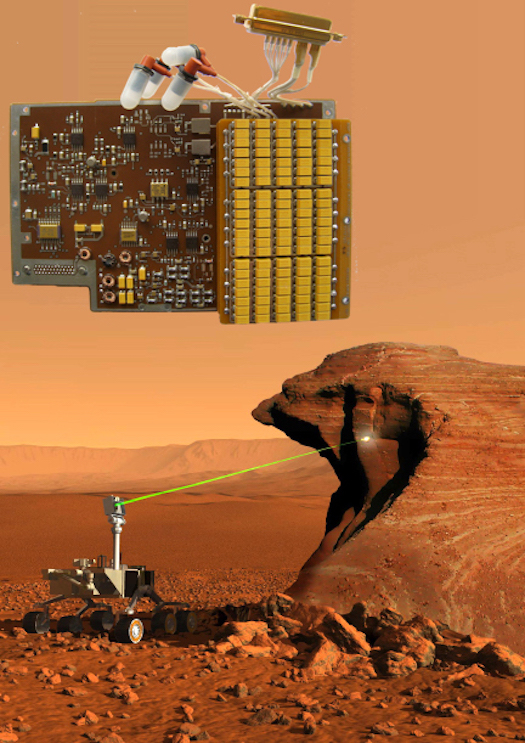

- Aerospace: Launch costs of roughly $10,000 per pound, extreme operating conditions, and the potential risk to human lives required capacitors to deliver improved functionality and utmost reliability in the most size- and weight-efficient packages possible.

AVX developed and supplied the 630 space-level, SRC9000 TBM Series ultra-low-ESR, multi-anode tantalum capacitors that are responsible for powering Curiosity’s ChemCam laser module.

- Consumer: Commercial versions of advanced defense, space-grade, and other high-reliability capacitors shrank living-room radios down to portable boomboxes and then cassettes, CDs, and MP3 players; turned vacuum-tube televisions into flat screens; and rotary phones into wireless, mobile, and now smartphones, which contain about 1,000 MLCCs in slim and lightweight form factors with high functionality.

In this slideshow, EBN looks at the ongoing development of miniaturized capacitors and the technology behind them. Click on the image below to read the rest.

Advertisement

Learn more about Electronic Products Magazine